Outlook

趨勢展望

Towards Zero-Waste: ECOVE Strives to Build a Circular Economy

The traditional linear economy operates under the model of “excavate, manufacture, use and dispose”. Mass consumption and disposal means that raw materials are being depleted in an unprecedented rate. ECOVE understands that Earth’s resources are limited in both sense of access and quantity and that is why we have been extending our reach into resource recycling and green energy, recycling PET bottles for manufacturing of synthetic fibers, setting up solar power farms for clean energy and recycling wastewater for reuse. These operations meet the objectives of the global initiative of “Circular Economy” and have positive impact on the sustainability of the environment.

Every Resource Counts: Innovative Business Model in Circular Economy

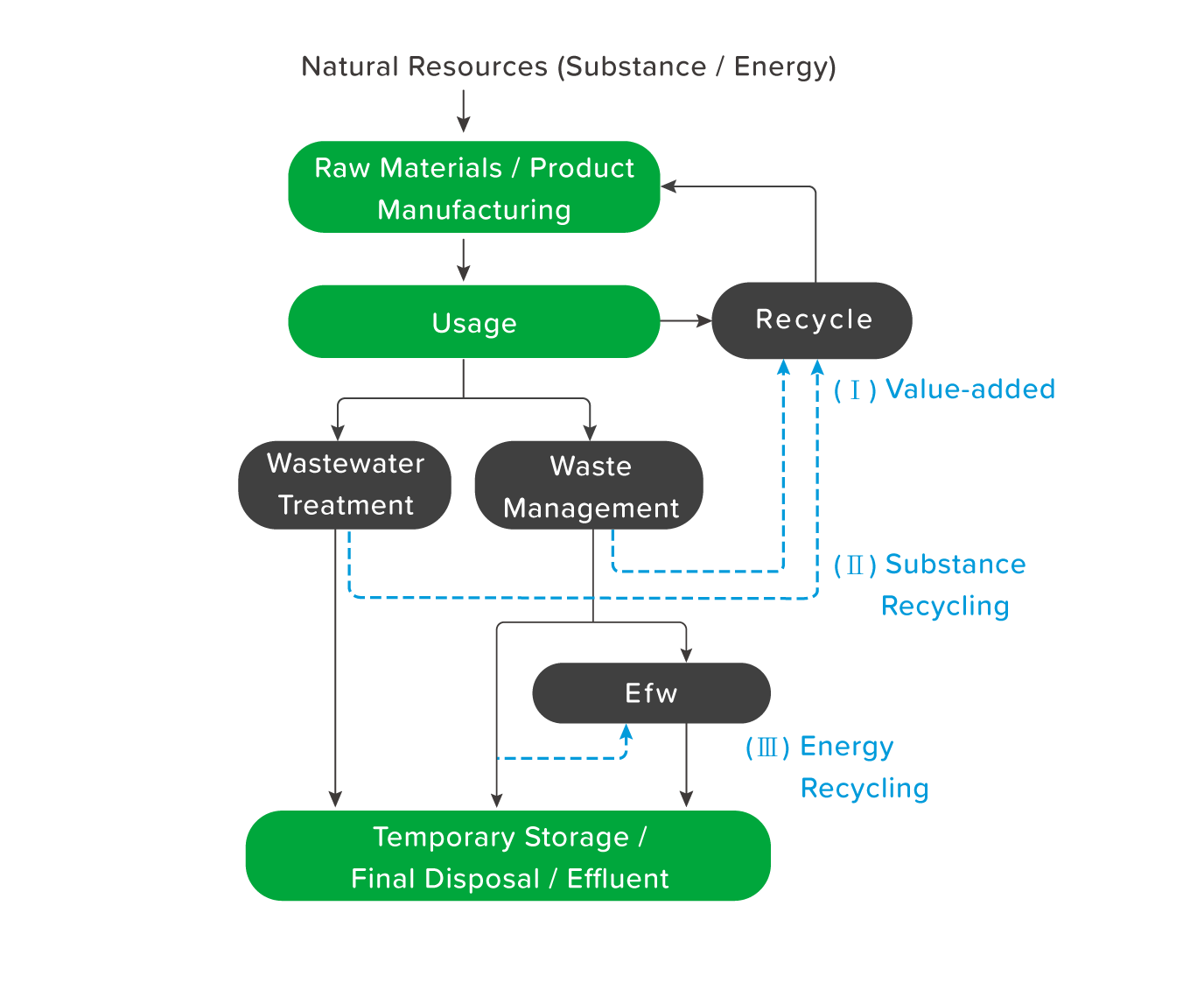

ECOVE started its development of circular economy from energy-from-waste (EfW) and waste management, which are embodied in the innovative operations of resource recycling, substance recycling and value-added reuse, sprung from the model of “extending life cycle, re-manufacture and reuse (Figure 1).

Figure 1. The circulation of substances / energy.

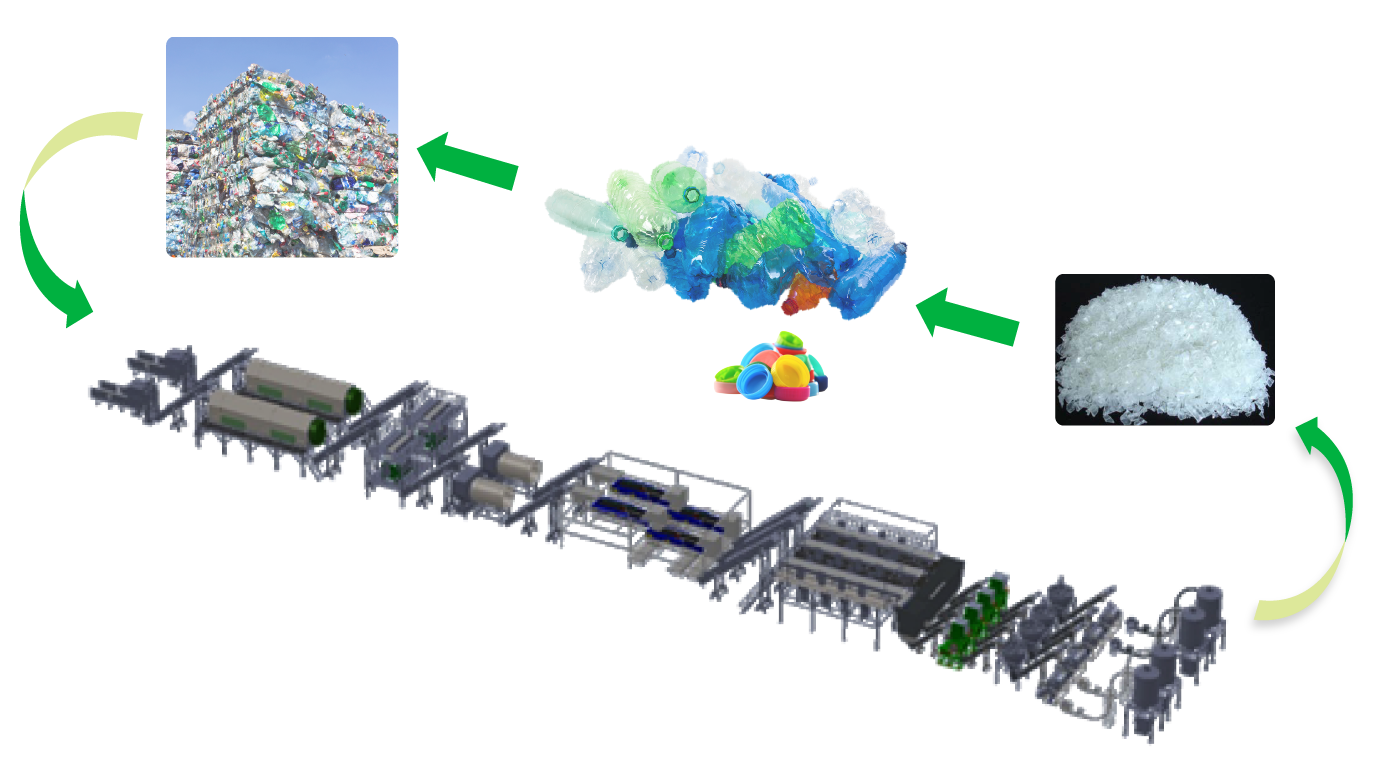

Take “Value-added (I)” in Figure 1 above for an example: The technical-based industry in Taiwan continues to innovate, which brings advanced manufacturing processes and expansion of production that generate massive and complex wastes in mixed forms of solids, sludge, solvents, acid/alkaline wastes and other liquids. Due to limited mature technology most recycling practices can only do secondary reuse in the current stage, which means that it is very difficult for these recycled substances to return to the original manufacturing processes. Currently, ECOVE is actively upgrading the existing recycling technology or seeking cooperation opportunities with research institutions worldwide that have already had mature technology to increase the value of recycled waste solvents. “Substance recycling (II)” in the figure above can be demonstrated by “PET bottle recycle”. At the current stage, ECOVE already has sufficient technology to separate the refuse from the path to the incinerator and process (cleansing and granulation) these bottles into varied substances for different manufacturing processes, such as fibers for functional, fireproof and sanitary garments and products. The recycled plastic can even be re-manufactured into PET bottle again. This has effectively reduced the use of raw materials for the manufacturers of synthetic fibers and cut down the reliance on primary raw material sources (as shown in Figure 2 below).

Figure 2. The waste PET bottle recycling: recycled products can be used for manufacturing PET bottles and synthetic fibers after the process of cleansing, cutting and granulation.

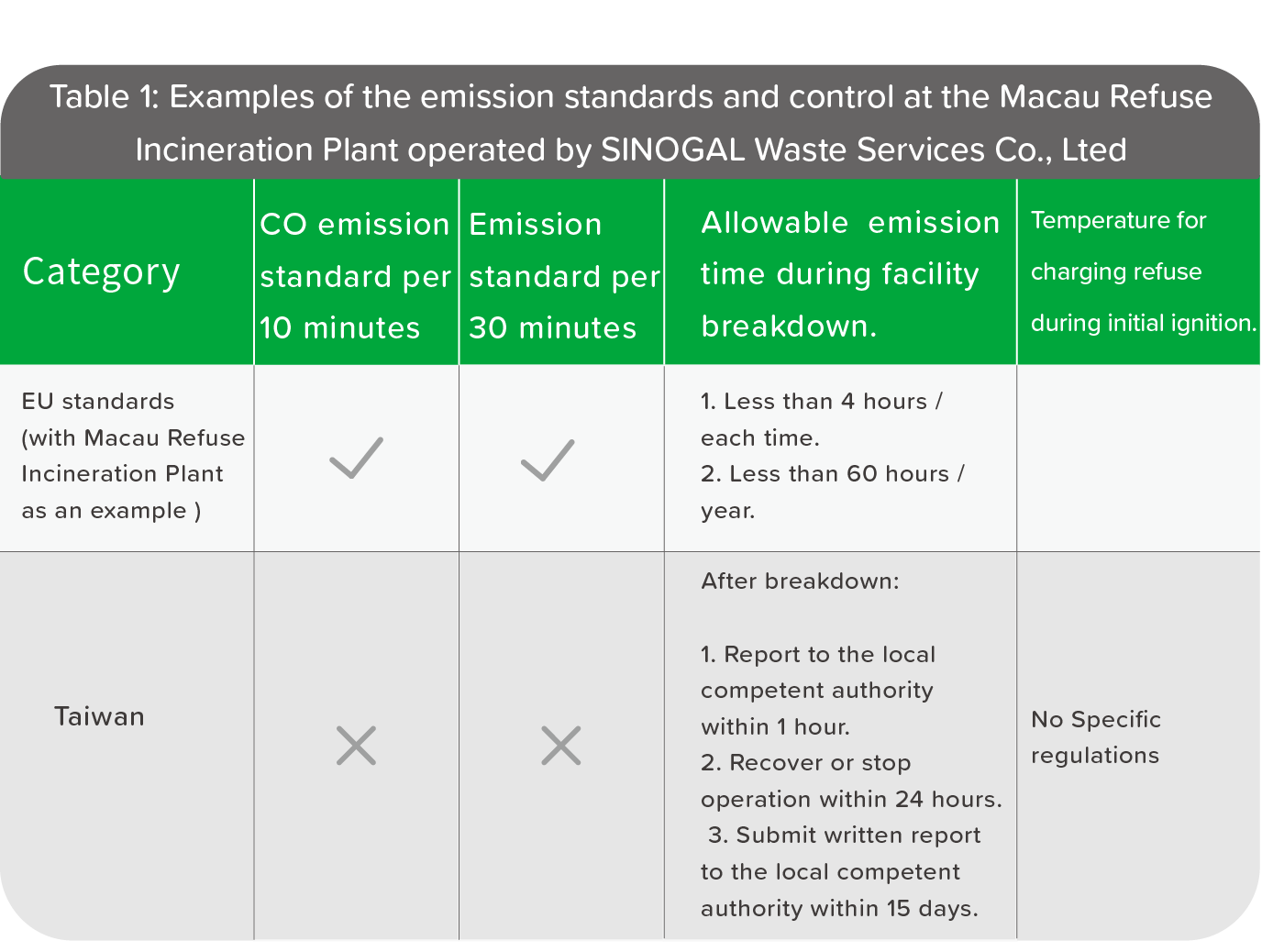

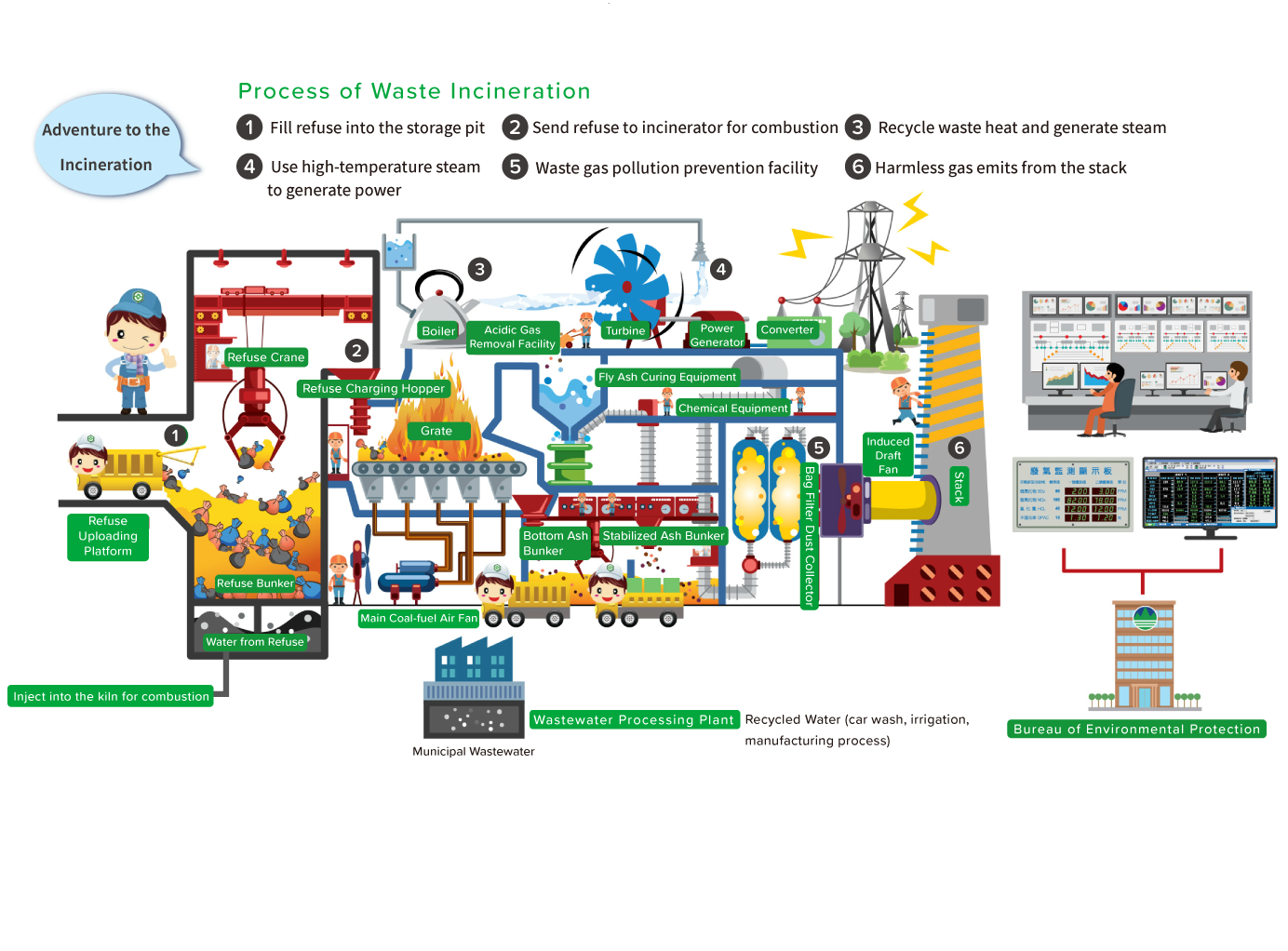

For “Energy recycling (III)” in Figure 1, abstracting heat from the incineration process and turning it into power has been a specialty of ECOVE. This power has been supplied to the industries for production or to the public for household use (as shown in Figure 3). This technology enables effective use of the final value of the refuses and replaced the traditional mode of fossil-fuel based power generation. At the same time, ECOVE actively seeks innovative breakthroughs in technology and operations. The first EU-standard EfW plant in Asia, Macau Refuse Incineration Plant, is operated by SINOGAL-Waste Services Corporation, a subsidiary of ECOVE Environment Corp. This testifies that ECOVE Environment Corp. has become one of the best energy-from-waste (EfW) operators in Asia’s energy recycle industry.

A New Record: SINOGAL Operates the Only EU Standard EfW Plant in Asia

Currently, the EU standards are benchmarks for incineration power plants worldwide. Achieving compliance with the stringent EU standards means that the operator has the capabilities to control hazardous substances and minimize the risks to human body and the environment. In 2009, SINOGAL took over the operation of Macau Refuse Incineration Plant, the only EU-standard (2010/75/EU) incineration center in Asia, which operates under a set of emission standards that is more stringent than the standards required in Taiwan.

Figure 3. The process of waste incineration and energy-from-waste(EFW).

To ensure that the Macau Refuse Incineration Plant meets the EU requirements, SINOGAL and its affiliated companies carried out a full-scale revamp on the facility, drawing knowledge and skills from nearly 20 years of experiences in incinerator operation, service and upgrade. The team began from confirming the start and stop mechanisms of the burner and improving the chemical dosing logics for the flue gas treatment system and, at the same time, established standard operating procedures for stocking and mixing the refuse in bunker and stirring of the refuse. An intelligent management and waste discharge warning system was also added to the central control room to provide the operators adequate alerts for timely responses. Since SINOGAL took over the operations, its performance has been highly recognized and the Macau Refuse Incineration Plant has been operating smoothly. On February 8, 2018, SINOGAL was further commissioned to implement the “Macau Refuse Incineration Plant Major Facility Upgrade Project”. This upgrade project is expected to extend the service life of the equipment and facilities and ensure continuous and stable operation of the Macau Refuse Incineration Plant. Looking into the future, ECOVE will continue to focus on applying technical knowhow to advance efficiencies in resource cycling, actively participating in national/regional policy, community collaboration and contribution. Along the development of the market we are seeking solutions to promote the practices of “circular economy” in the society. We strive to become the most reliable provider of industry-leading “resource cycling” services.