Innovation

企業創新

ECOVE Introduces the EGR Technology to Optimize the Effectiveness of Air Pollution Control

Wujih Energy-from-Waste (EfW) Plant is the first BOT plant in Taiwan. It is invested, developed, and operated by ECOVE Wujih Energy Corporation; Operation and maintenance are carried out by ECOVE Environment Services Corporation. In recent years, numerous awards had been won in the national EfW plant audit in recognition of it's strict environmental and safety standards including” Excellence Award” in 2017 and” Special Award for Energy Saving Technology” in 2016. In addition to striving to improve the ” resource cycling efficiency™ ", ECOVE embraces it's responsibility to environmental protection by promoting international environmental awareness and environmental sustainability. It is a precedent in the Taiwanese industry. The EGR technology used at the Wujih EfW Plant helped reducing Nitrogen Oxides(NOx) formation and made a concrete contribution to the prevention and control of air pollution in the central region.

ECOVE Takes the Lead in Adopting EGR Technology

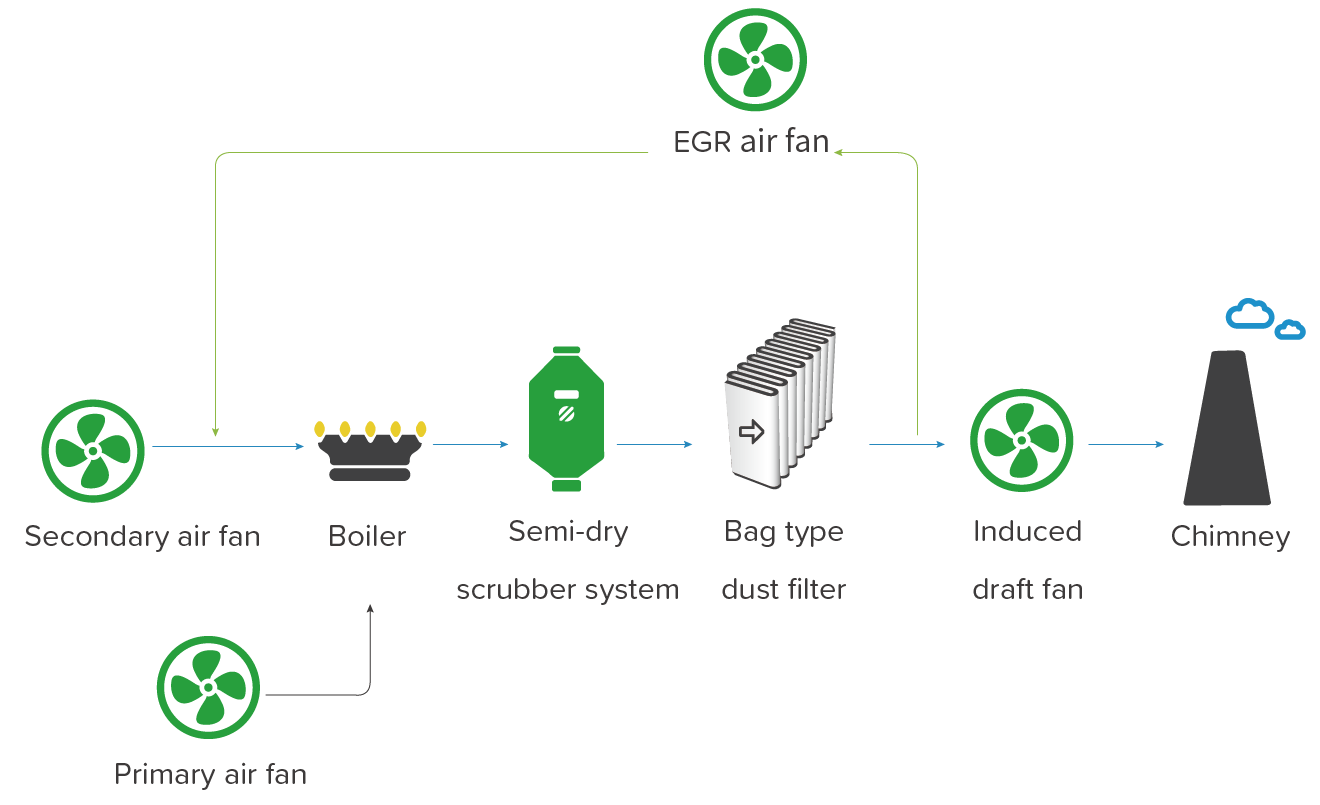

Burning of waste in high-temperature generates nitrogen oxides. Nitrogen oxides can be classified into three different types according to their formations: (A) Thermal-NOx: formed in the reaction of nitrogen and oxygen during high-temperature combustio; (B) Rapid type nitrogen oxides. (Prompt-NOx): The molecular bonding of waste materials at the moment of high-temperature destruction produces highly reactive free radicals (reaction intermediates) which react with nitrogen in the combustion air; (C) Fuel nitrogen oxides (Fuel-NOx): The nitrogen component of the waste itself reacts with oxygen. Discharging these nitrogen oxides will cause environmental hazards such as acid rain and photochemical smog. Therefore, it is necessary to strictly control its emissions. Nitrogen oxides generation in the waste incineration process is almost unpreventable. In general, Energy-from-Waste (EfW) plants use flue gas treatment technologies such as "selective catalyst reduction method" or "selective non-catalytic reduction method" to reduce nitrogen oxides to harmless. Wujih EfW Plant is built to use the selective non-catalyst reduction method where ammonia water is injected as a reducing agent to create the reaction with nitrogen oxides. Once treated, the harmless air is then discharged to the atmosphere. To meet the regulatory requirements, large amounts of ammonia water are needed to remove the nitrogen oxides from these incineration processes. ECOVE thus embarked on a new EGR technology development program and applied the technology to the EfW plants it operated. The program has achieved gradual results in air quality maintenance. The so-called EGR can be interpreted as "exhaust gas recirculation technology". As the name suggests, a certain proportion of exhaust gas is "reflowed" to the combustion zone in place of the fresh secondary wind. With low oxygen content, low temperature and high inert gas composition, the exhaust gas is able to suppress the genetic condition of nitrogen oxides. ECOVE uses this principle to set up an EGR fan between the bag filter and the induced draft fan in the Wujih EfW Plant to draw some of the exhaust gas back into the secondary combustion air circuit. The secondary air duct is injected into the combustion zone to perform "reflow" of the exhaust gas.

Figure 1. Schematic diagram of the EGR system of the ECOVE Wujih EfW Plant.

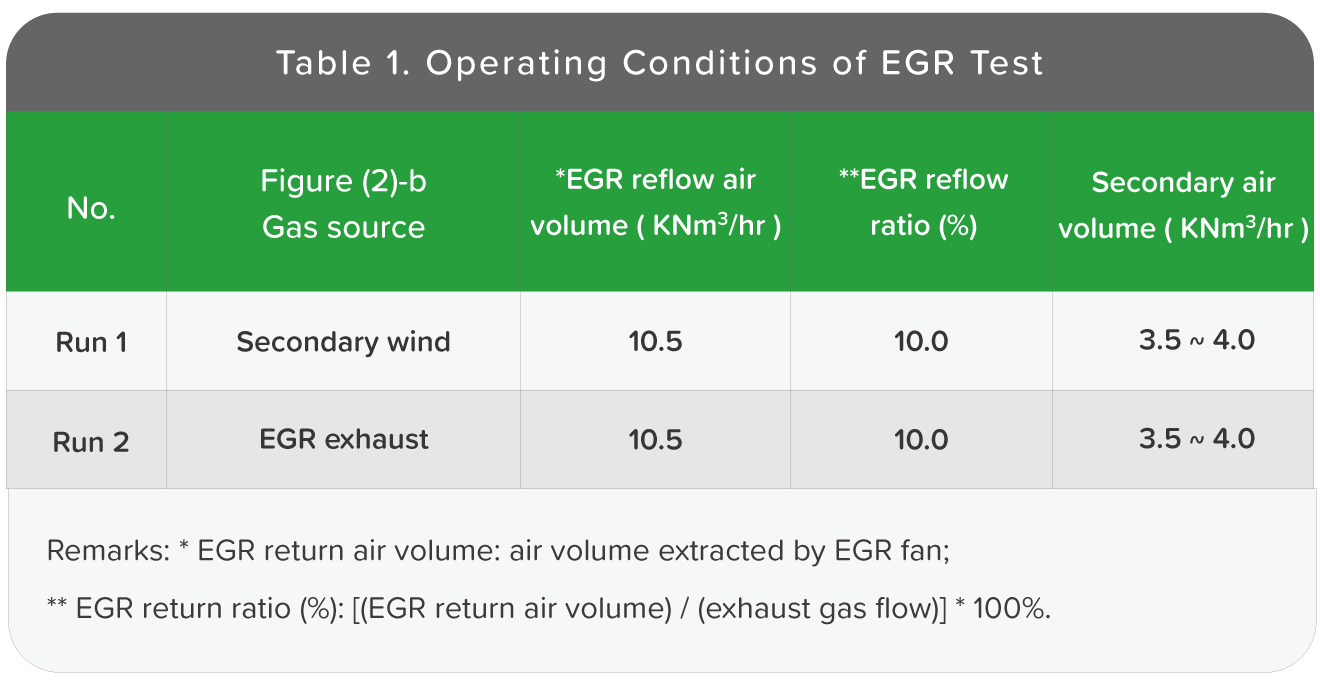

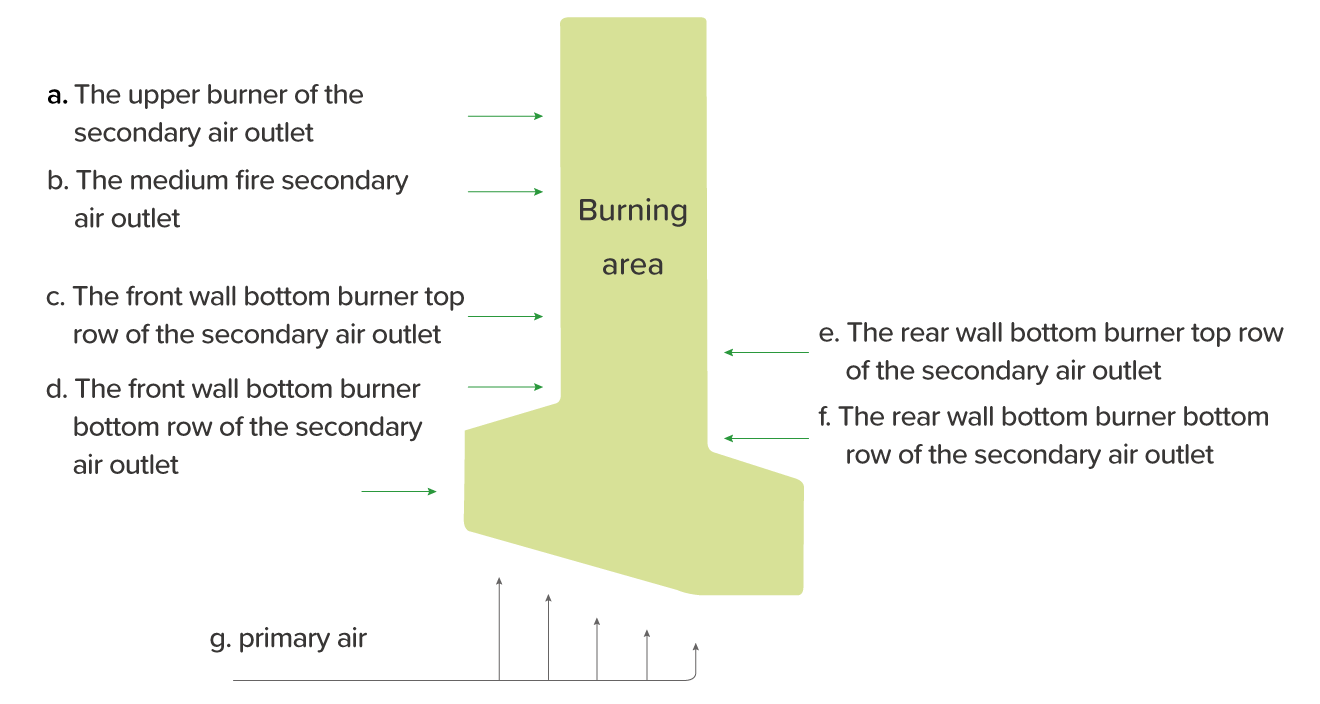

The EGR system enters the combustion chamber after passing through the secondary air duct. The distribution ratio of the secondary air and the EGR exhaust air volume will affect the effectiveness of the EGR system. As shown in Table 1, Run1 and Run2 are used to test the return air supply under the front wall bottom burner as well as the difference between the fresh secondary winds. The results showed that (Run2) the front wall bottom burner supplied a better amount of ammonia water. After establishing the secondary air and EGR exhaust gas distribution position, the different EGR recirculation ratio tests were carried out. The results show that the optimal ammonia water consumption can be obtained when the return flow rate is controlled at 10%, which is 25% lower than that before the EGR system is activated.

Figure 2. Location of the EGR gas injected into the secondary tuyere in the combustion zone of the incinerator.

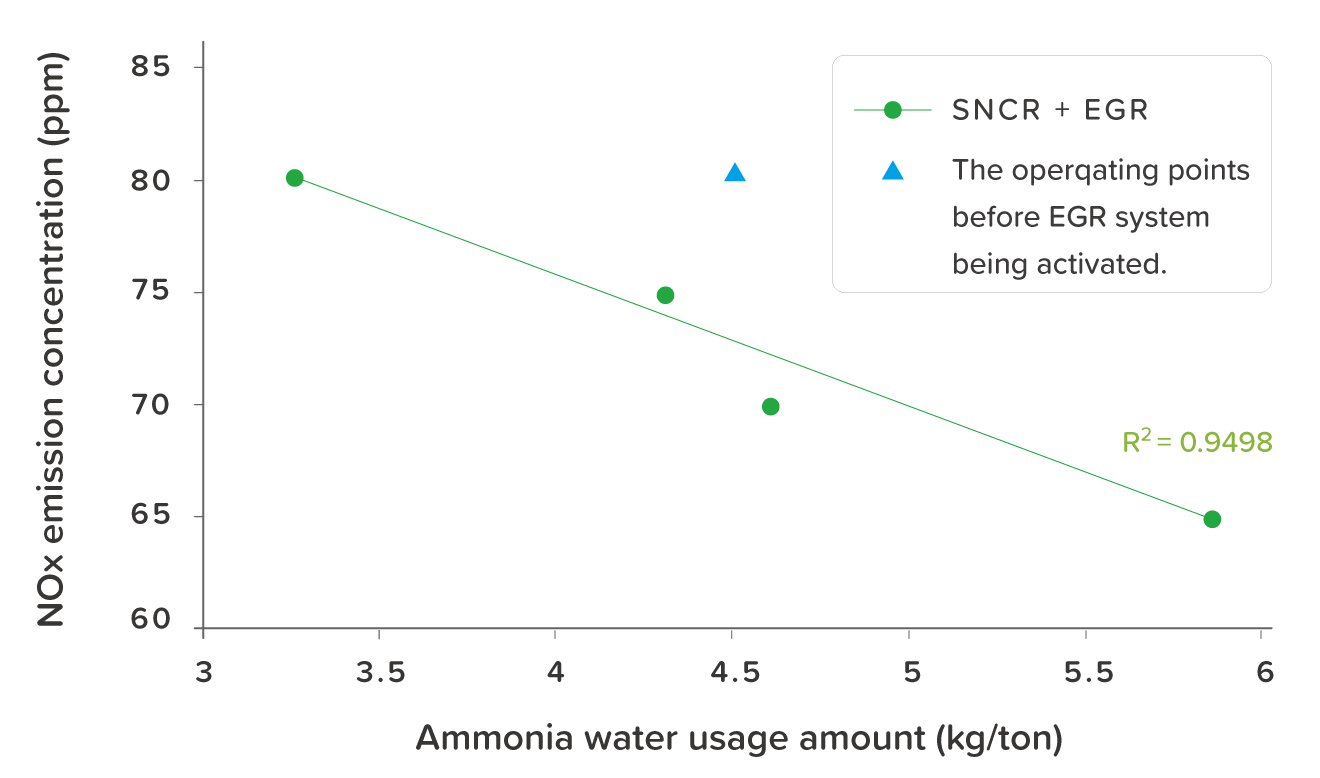

Secondly, regarding the air pollution improvement, The operation condition before and after EGR being activated are compared through statistical regression analysis. At the same ammonia water usage amount, NOx concentration can be reduced from 81.2 ppm to 72.5 ppm after the EGR system is activated, proving the effectiveness of EGR system.

Figure 3. Relationship between ammonia water usage amount and NOx emission concentration.

ECOVE Improves EGR Technology to Refine Pollution Control Effectiveness

EGR technology had been applied to EfW plant in foreign countries. Believing in the concept of ‘Resource cycling’ efficiency™ and air pollution prevention, ECOVE hopes to inspire existing stationary sources to upgrade and update their equipment by introducing it to Taiwan. It is a feat of domestic operation innovation. According to the test results: (A) When the EGR reflux ratio is controlled at 10%, the ammonia water dosage can be reduced by an average of 25%; (B) Under the same ammonia water usage amount, nitrogen oxide emission concentrations can be reduced from 81.2 ppm to 72.5 ppm with the EGR system is activated. (C) The decrease in fresh secondary air volume reduces the total exhaust volume of the chimney, resulting in a reduction in total nitrogen oxide emission from the chimney. From the above three points, EGR system has can effectively suppress the formation of nitrogen oxides, but the concentration of nitrogen oxides is inhibited due to the limitation of 6% oxygen content required by the dioxin control of the incinerator and the requirements of Article 7 of the emission standard. The effect is not as significant as the literature example of foreign EGR systems used in EfW plants. In the future, ECOVE will continue to advance in EGR technology focusing on EGR exhaust, primary and secondary air injection, distribution ratio and airflow disturbance. Under the effluent standards, a breakthrough to the current EGR technology will be found so more reduction of nitrogen oxides can be achieved.