Key Technology

關鍵技術

ECOVE Wins Environmental Protection Awards

The industrial manufacturing processes in Tainan Science Park are rapidly evolving. Numerous types of waste require processing and are complicated in nature. The processing procedures include incineration, solidification, physico-chemical treatment, and landfill. There has been no pollution, disputes, violations, or any other disputes since ECOVE took over the Tainan Science Park Resource Recycling Center. ECOVE has also advanced various energy conservation and carbon reduction measures to contribute to the Park's advancement into a low-carbon and sustainable industrial park and become the paradigm of energy conservation and carbon reduction measures for privately-operated waste processing plants in Taiwan.

Figure 2. ECOVE employees execute waste solvent disposal and collection at the Tainan Science Park Resource Recycling Center.

ECOVE Provides Proprietors with a Total Solution for Industrial Waste

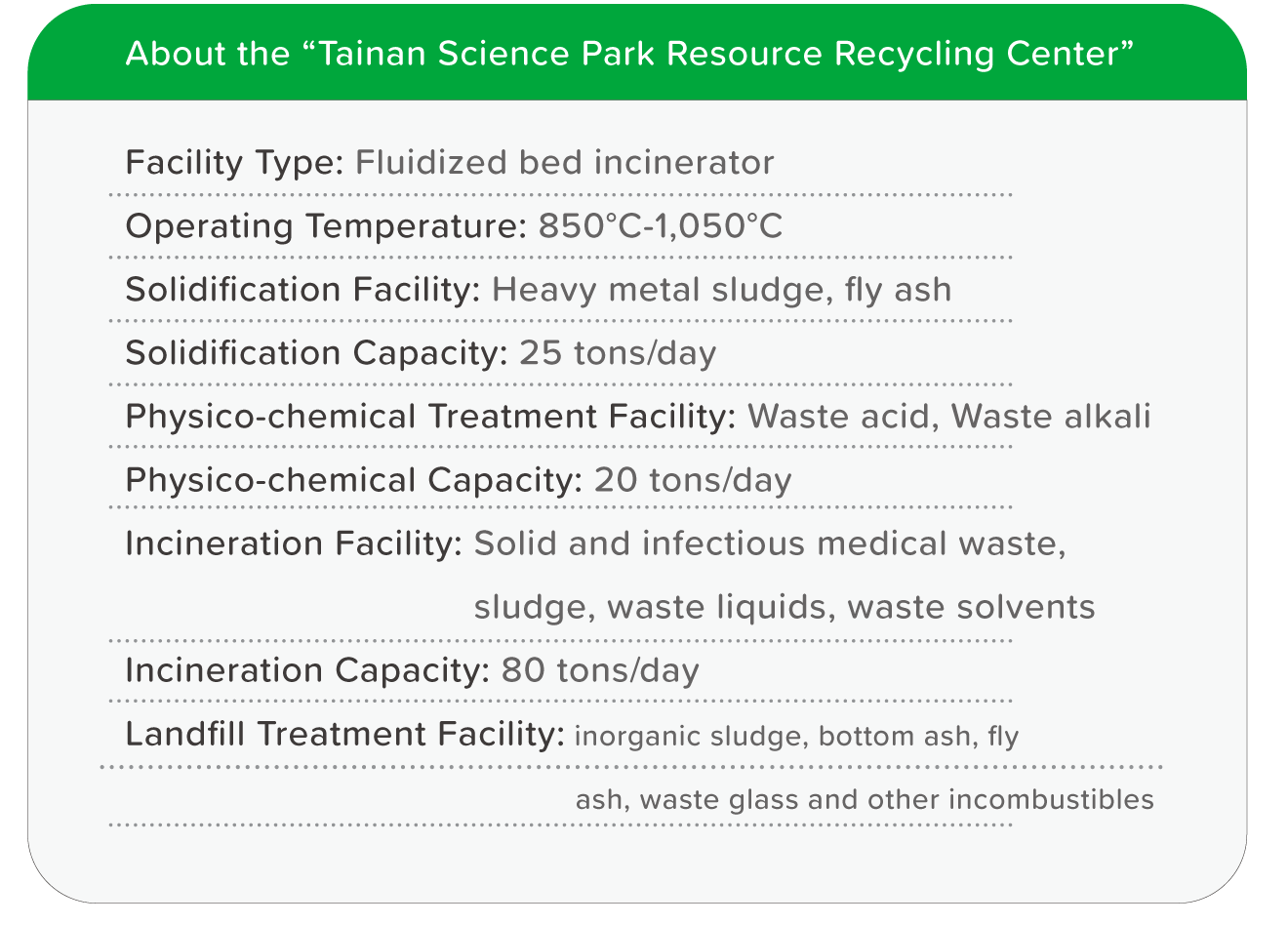

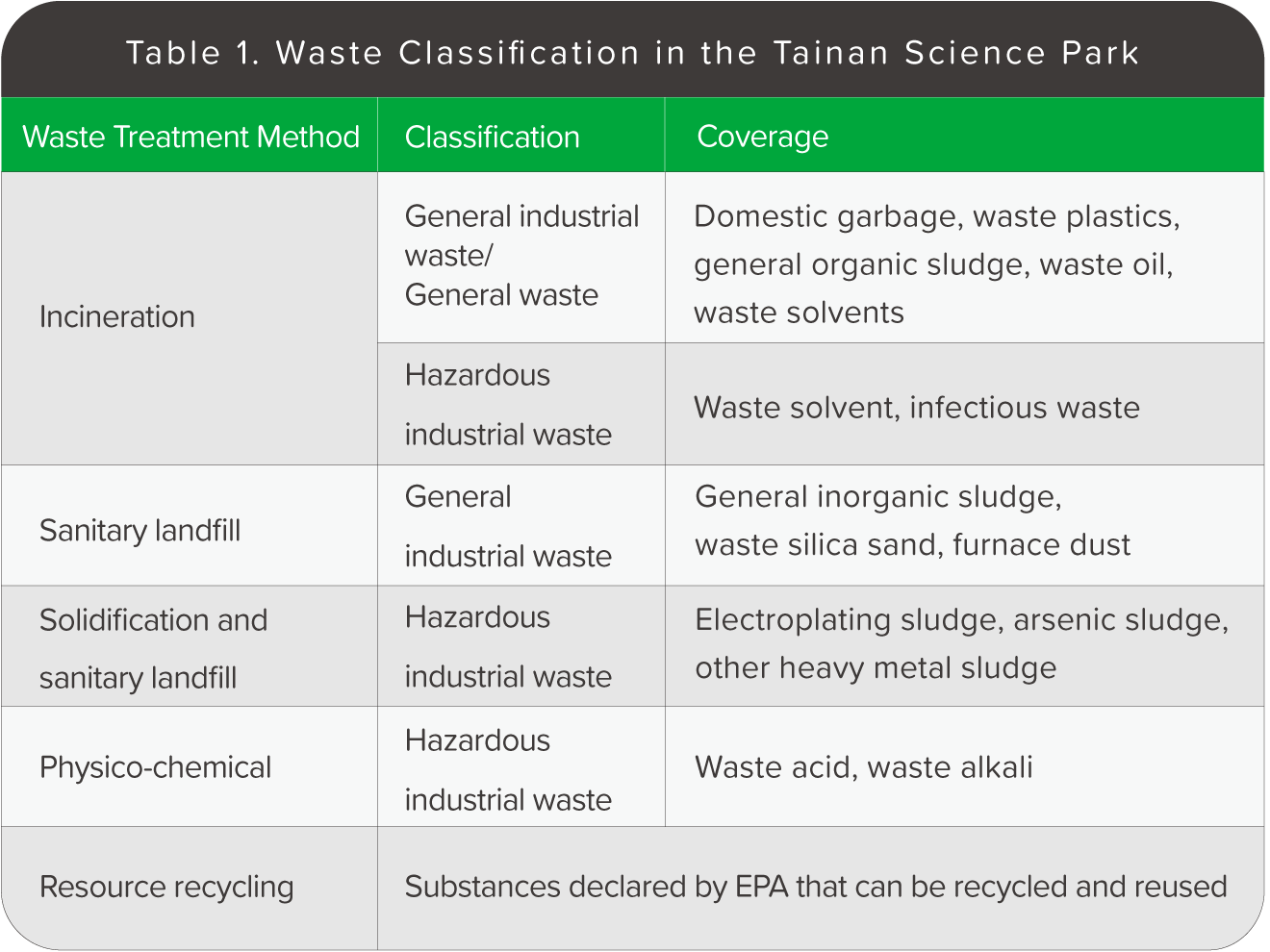

The daily operations of Tainan Science Park (hereinafter referred to as "the Park") include general domestic waste as well as general industrial waste and hazardous industrial waste. There are more than one hundred types of waste and the forms of waste encompass solids, fluids, and sludge (as shown in Table 1). The waste is diverse and complicated in nature, particularly the storage, processing, and transportation of waste solvents. The Park must consider the safety of storage, compatibility of solvents, corrosiveness, production volume of the source, frequency of disposal, and the issue of non-flammable items in the waste. These issues all contribute to difficulties in operations.

The processing facilities of the Tainan Science Park Resource Recycling Center(hereinafter referred to as "the Center") must include the preliminary processing, incineration, solidification, physico-chemical treatment, and landfill functions (the procedures are specified in Figure 2) to adequately resolve all types of industrial waste with complicated properties. During construction, the Center adopted a “fluidized bed incinerator” that can process solids, liquids, and sludge at the same time. This type of fluidized bed has a wide surface and achieves high combustion efficiency for crushed solid waste. The bed concentrates high volumes of heat and it can complete incineration of different items at the same time. ECOVE has accumulated more than twenty years of experience in operating incinerators and it provides flexible adjustments to parameters for waste processing to achieve optimal performance of fluidized bed incinerators.

Figure 3. Waste processing procedures of the center.

Establishment of a Smart System to Improve O&M Quality

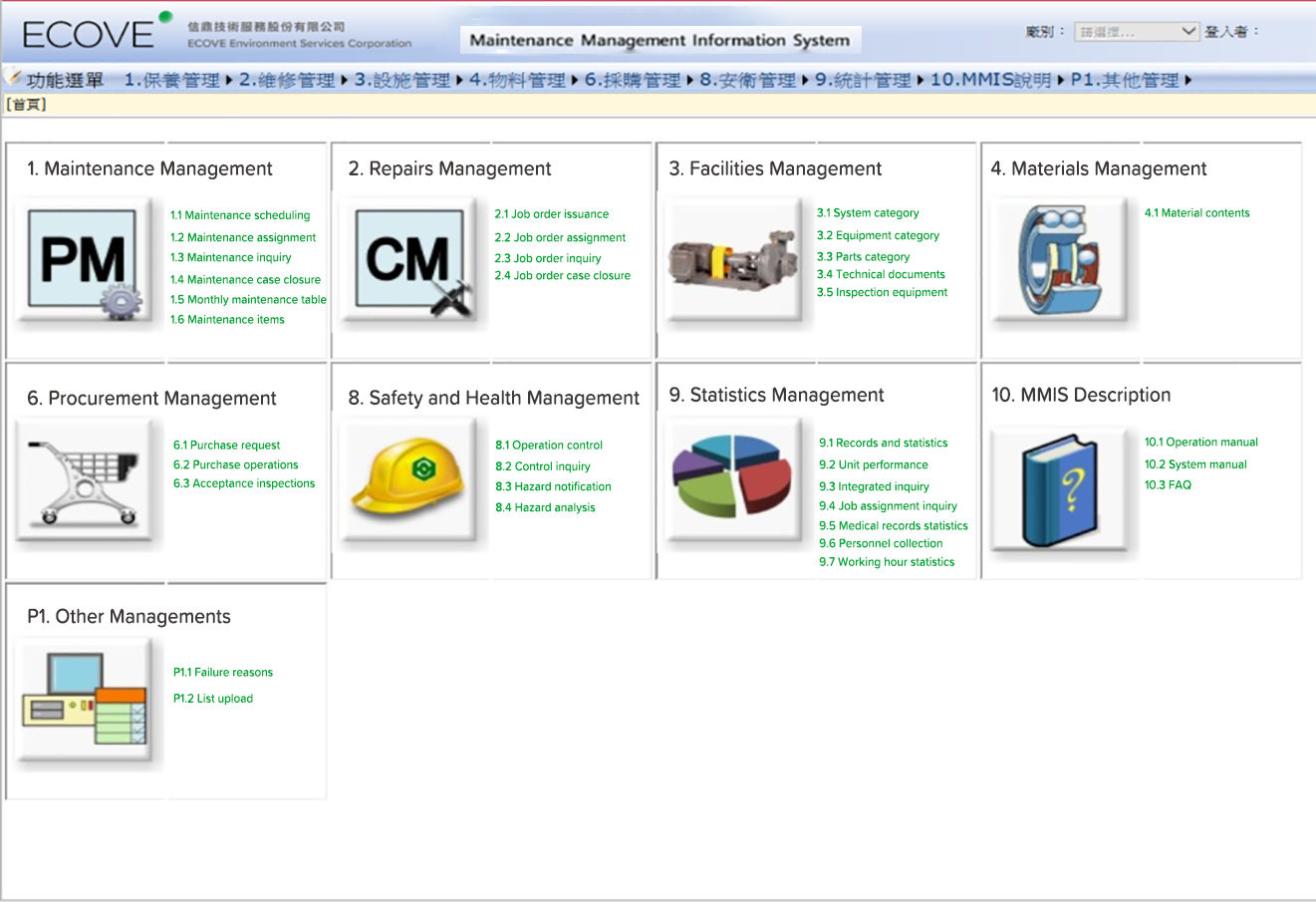

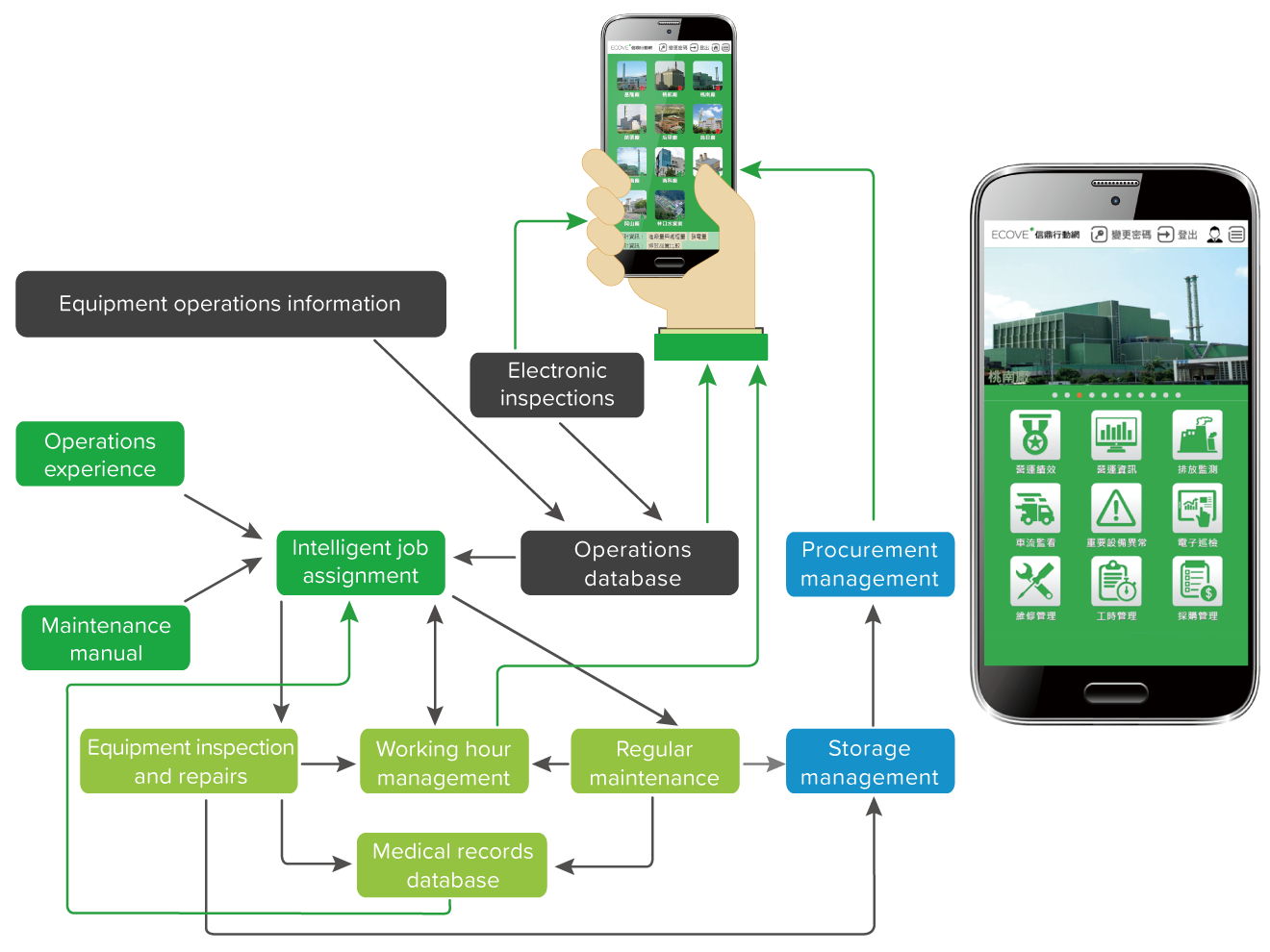

To adequately process industrial waste in the Park, ECOVE has established rigorous management measures for the entry of waste in the plant, including waste entry application, entry control procedures, waste storage control, control of processing destination, and operations based on reports and forms. In addition, ECOVE works tirelessly for the maintenance and servicing of plant equipment. In addition to periodic maintenance plans, it has also established the Maintenance Management Information System (MMIS), electronic inspections, and IOI intelligent monitoring system to process waste, improve production efficiency, resolve materials degrading, and improve the reliable of equipment operations.

Figure 4. ECOVE established the “Intelligent Maintenance Management Information System” that includes a database for maintenance, repairs, facilities, materials, procurement, and safety and sanitation.

Figure 5. ECOVE goes beyond time and spatial restrictions and uses cloud management to view anomaly reports and information for various plants.

Active Promotion of Source Reduction to Improve Resource Recycling Rates for Enterprises in the Park

ECOVE also advances the government’s “zero landfill” policy to actively advance waste reduction and reuse for various industries and uses Park assistance and verification mechanisms to promote source reduction and resource recycling concepts. ECOVE also provides diverse consultation and assistance channels that include onsite conversations, telephone, fax, and email. The recycling rate of the Park in 2017 reached 85.86% and 100% of the waste delivered to the Center was properly processed.

Full-capacity Operations for Five Consecutive Years to Promote Industrial, Economic, and Environmental Sustainability

Waste processing is an important task for the country’s environmental protection. ECOVE has more than twenty years of professional experience in the operations of incineration plants and it has operated urban refuse incineration plants to waste disposal and management of multiple hazardous industrial waste in the Tainan Science Park. The company is familiar with environmental protection laws and the characteristics of various hazardous waste, which satisfies the requirements for waste cleaning by competent authorities in the Park and various enterprises. With outstanding management experience, the Center has operated at full capacity for five consecutive years under ECOVE without any “unplanned downtime” and all operations have been normal. ECOVE adequately processes industrial waste for all enterprises in the Park to concentrate on R&D and production with peace of mind and indirectly contribute to the development of the national economy. ECOVE aims to become "the most reliable provider of industry-leading resource cycling services.” In addition to full dedication to the normal operations of the Center, it also actively contributes to an ecological environment in the Park. It has won the silver award for “ROC Enterprise Environmental Protection Award” for three consecutive years, and it was also the first waste processing center in a science park in Taiwan to be awarded the “Honorary Environmental Protection Enterprise Award”. The company made positive contributions to the image of the owner (Southern Taiwan Science Park Bureau, Ministry of Science and Technology) and the Park, and it also made the Center the demonstration plant for energy conservation and carbon reduction for all waste processing plants in Taiwan while making the Tainan Science Park the role model for sustainable green science parks.