Outlook

趨勢展望

Highlight of Renewable Energy:

The Outlook for New Generation of EfW

Energy-from-Waste(EfW) is an important part of the circular economy. At ECOVE Environment Service Corp., we strive to implement the concept of circular economy development and evaluate the possibility of extending the operational life of aging EfW plants. Evaluations include margin inspection according to regulations, overall performance evaluation, and comprehensive equipment examination. We hope to use this opportunity to introduce advanced technologies into the existing EfW plants not only to improve the overall energy recovery efficiency but also to extend the amount of waste incinerated and take pollution prevention and control efficiency into consideration. We expect this new generation of EfW power technology to become a highlight for our country's renewable energy industry.

EfW Becomes Main Source of Renewable Energy

The EfW plant uses high-temperature incinerator to make the refuse harmless and stable. The heat generated by the incinerator can be recovered and reused for electric power generation. It is the main source of renewable energy in our country, together with hydroelectric power, wind power, and photovoltaic power. According to the 2017 annual statistics, the EfW plant generated 3.18 billion kWh of electric power, accounting for 20.3% of the total renewable energy generation in Taiwan. It is equivalent to one-third of the electric power supply by Taiwan’s first nuclear plant which can provide enough electric power to about 970,000 households per year. These statistics show that EfW plants play an important role in the field of renewable energy.

Figure 1. The main sources of renewable energy in Taiwan.

Although EfW plant for electric power generation accounts for a high proportion of the total renewable energy, most 24 EfW plants in Taiwan have been in operation for almost 20 years, and the average efficiency has decreased from 21.8% of the original design to 19.0% in 2017 in actual operation. Compared with the advanced countries such as Europe and the United States, the energy recovery efficiency of newly established EfW plants has exceeded 25% or even more than 30%. This shows that energy recovery efficiency still has room for improvement in Taiwan. If the energy recovery efficiency of each plant can be upgraded to 25% pursuant to "Regulations for Installation and Management of Renewable Energy Generation Equipment," an additional 1 billion kWh of electricity can be generated each year.

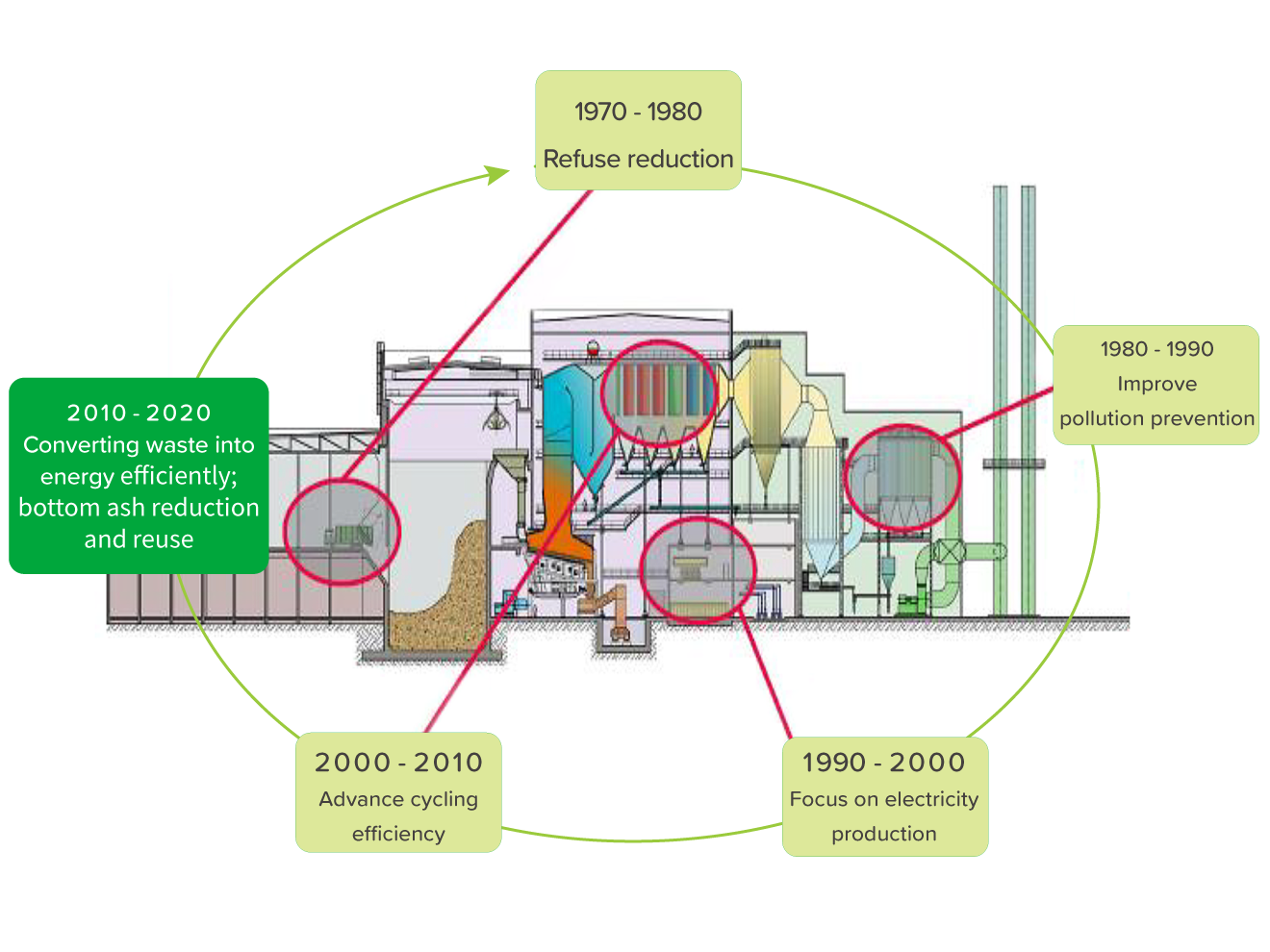

In response to the inefficiency of EfW plants, Environmental Protection Administration (EPA), Executive Yuan issued “Multiple Waste Disposal Plan” in June 2017, announcing that the central and local governments would invest NT$15.3 billion to upgrade the EfW plants by introducing new technologies such as advanced combustion, high-energy recovery efficiency, better pollution prevention. ECOVE has accumulated more than 20 years of experience in the field of EfW. With reference to the domestic situation and advanced foreign technology, it is suggested that the energy recovery efficiency can be improved in the following directions:

Figure 5. The timetable and content of the EPA's Multiple Waste Disposal Plan.

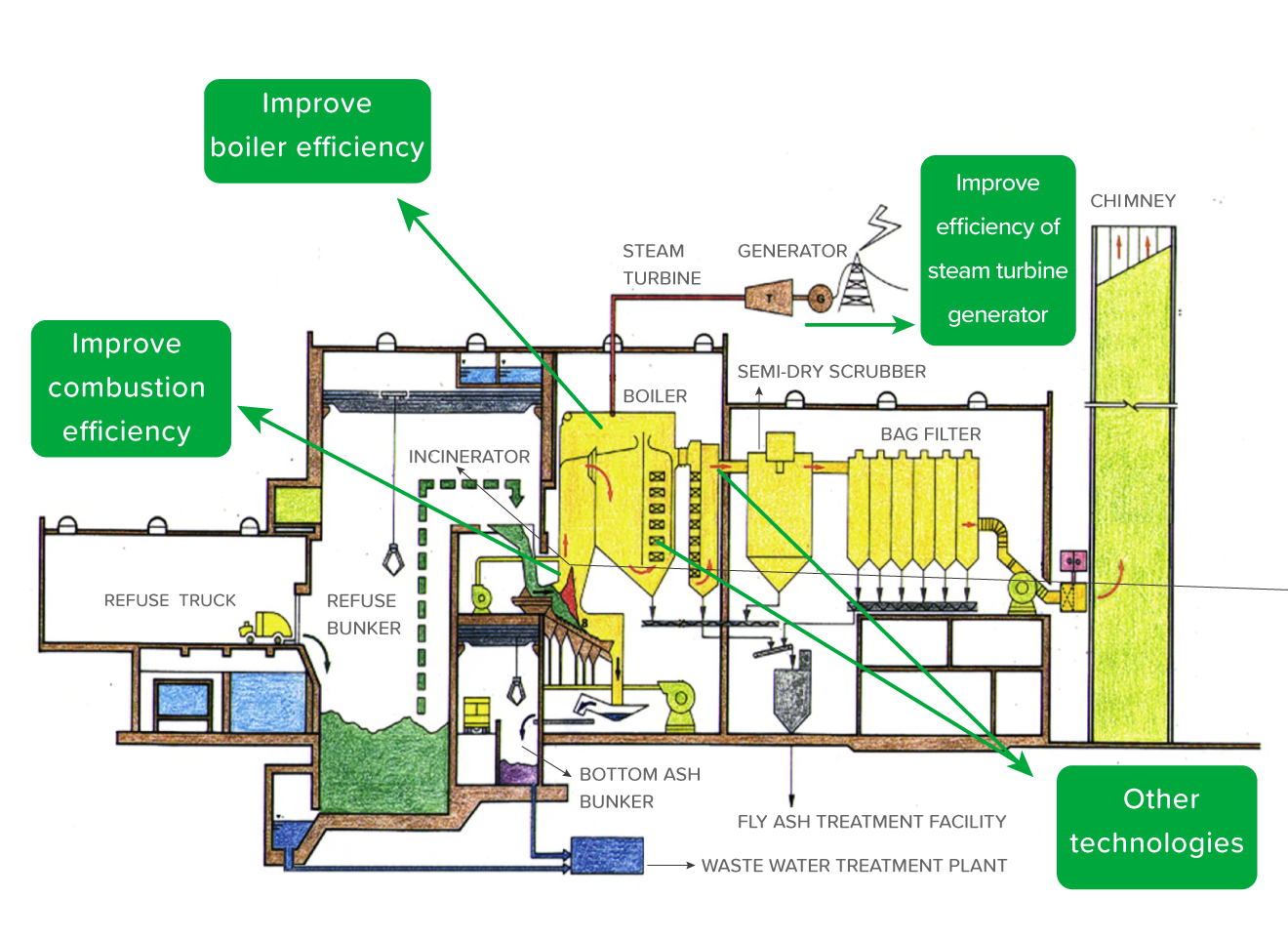

To Improve Combustion&Boiler Efficiency

In line with increasing heating value in Taiwan, the overall all combustion efficiency can be increased with the new type of grate technology and the combustion air volume ratio adjustment; at the same time, the water-cooled wall can be added beside the grate which can effectively reduce the clinkers, improve the boiler efficiency, increase the production of steam, reduce the temperature of the boiler exhaust gas and reduce the water consumption for flue gas treatment. In terms of the advanced foreign technology, boiler efficiency can be increased from the current 75 ~ 80% to more than 85%.

To Boost Efficiency of Steam Turbine Generators

With reference to advanced foreign technology, ECOVE suggests that increasing the efficiency of steam turbine generator can be achieved by improving the quality of the inlet steam and reducing the temperature and pressure of the outlet steam. The higher the steam quality of the steam turbine generator, the more electric power can be received. However, due to the boiler design and material changes, the steam turbine and generator must also be updated. Although the overall planning is more effective, the investment cost is high. The construction is difficult and the construction period is long. Therefore, it is also necessary to consider suitable ways of refuse disposal deployment in/between different counties and cities when building new plants. In addition, due to the generally insufficient capacity of air-cooled condensers designed in earlier Taiwan, many plants had high temperature and pressure at the exit of steam turbine, and heat energy couldn't be effectively converted into electrical energy. The limited plant space also restricted improvement; however, with the advancement of air-cooled condenser technology in recent years, the possibility of improvement is foreseeable.

Enhanced Performance Technologies

Shock wave cleaning device can be used for the boiler tubes replacing the traditional steam soot blowing, which would effectively maintain the boiler efficiency and the overall power productivity because there is no steam consumption. In addition, strengthening the low-temperature heat energy recovery in the plant such as boiler exhaust gas heat and heat pump application would help increase heat reuse. Besides increasing the electric power generation, electric power saving can also be implemented by replacing old motors with new energy-saving motors; inverter can be installed as well on fans with large power consumption to further enhance the energy recovery efficiency of the whole plant.

Figure 6. Energy recovery efficiency improvement methods for incineration plants, as illustrated in the green circles.

Other than the above-mentioned hardware improvements, most domestic and international Energy-from-Waste plants have adopted advanced automatic combustion control technology and intelligent management. The parameter of feed and combustion air volume can be automatically adjusted via the system to improve operational stability and energy recovery efficiency. As a leader in the EfWaste operation and maintenance industry in Taiwan, ECOVE has placed great importance in the technological development of intelligent management. Through the integration of upstream and downstream sectors and Big Data analysis, ECOVE has already developed a system to feedback all EfW plant information to the terminal interfaces. By combining aspects of the operation, maintenance, and management, the system improves the stability of the overall production and ensures that the overall renewable energy recovery efficiency remains at a high level.

Breaking through the Limits&Look forward to the Future

ECOVE's parent company, CTCI Group, formed a cooperation alliance with Evergreen Steel in 2018 to obtain the “Taoyuan City Biomass Energy Center BOT Case”, which will increase the overall energy recovery efficiency to over 28% by implementing advanced technology, overall plant organization, utilization of combustion efficiency, waste heat utilization,high-temperature steam, the exhaust gas heat energy recovery, high-efficiency steam turbine generator, and high-efficiency air-cooled condenser. It sets the best example for Taiwan's EfW plant that uses advanced technology to create an energy recovery efficiency breakthrough.

However, compared with the overall organization of the new plants, the existing EfW plants face issues such as appropriation budget, existing space, existing civil structure, and pressure of handling refuse treatment, which leads to the limitation of construction period, and limits the possibility of efficiency improvement, making it difficult to achieve 25% energy recovery efficiency. Once the energy recovery efficiency of the existing plants cannot reach the threshold of 25%, the rate of concession in “Regulations on the Management of Renewable Energy Power Generation Equipment” (NTD3.8945 per kWh) will not be applied, and the willingness to improve the efficiency of rectification will be reduced. It would be a pity if the energy from waste is not properly used. It is suggested that the competent authority may consider lowering the power recovery efficiency of 25%, allowing old plants to apply for a higher renewable energy purchase rate after the renovation to support the high cost of construction. What's more, due to a long time for rectification, the pressure of handling refuse disposal in various counties and cities may occur during construction. The concept of regional defense of the Environmental Protection Agency must be established at this time, and the rectification schedule of each plant should be carefully planned. The central government should coordinate the deployment with counties and cities supporting the plan to create a more flexible timetable for rectification of the construction period.