Key Technology

關鍵技術

ECOVE Provides Recycling & Reusing Service for Waste Solvents

ECOVE strives to improve "resource cycling" efficiency™ by focusing on reducing the consumption of petrochemical resources and raising the resources usage rate based on the solvent recycling. Therefore, ECOVE Solvent Recycling Corp. was founded in 2018 to increase the quality of waste IPAs recycling by improving process equipment and provide recycling and reusing service for chemical solvents and waste solvents. It will not only help expand the layout of ECOVE in the area of a circular economy but also make a specific contribution to recycling and reuse of waste solvents in Taiwan.

Reusing of Recoverable Waste IPAs

The electronic components industry is the main force of Taiwan exporter. During their production process, a massive amount of chemical agents and solvents are used, such as photoresists, developing the solution, etchants, acetone, isopropyl alcohol, etc. It is considered as waste after usage and to be combusted in incinerators. These effluents, in practice, are reusable. It is wasteful to discard them as disposable commodities. Take isopropyl alcohol, it is often used for the development process and substrate cleaning in the electronics industry. However, isopropyl alcohol effluents can be recycled and reused after the concentration. With the development of advanced semiconductor processes in Taiwan, the amount of isopropyl alcohol required is projected to increase progressively, generating market demands for the disposal and reusing of waste IPAs.

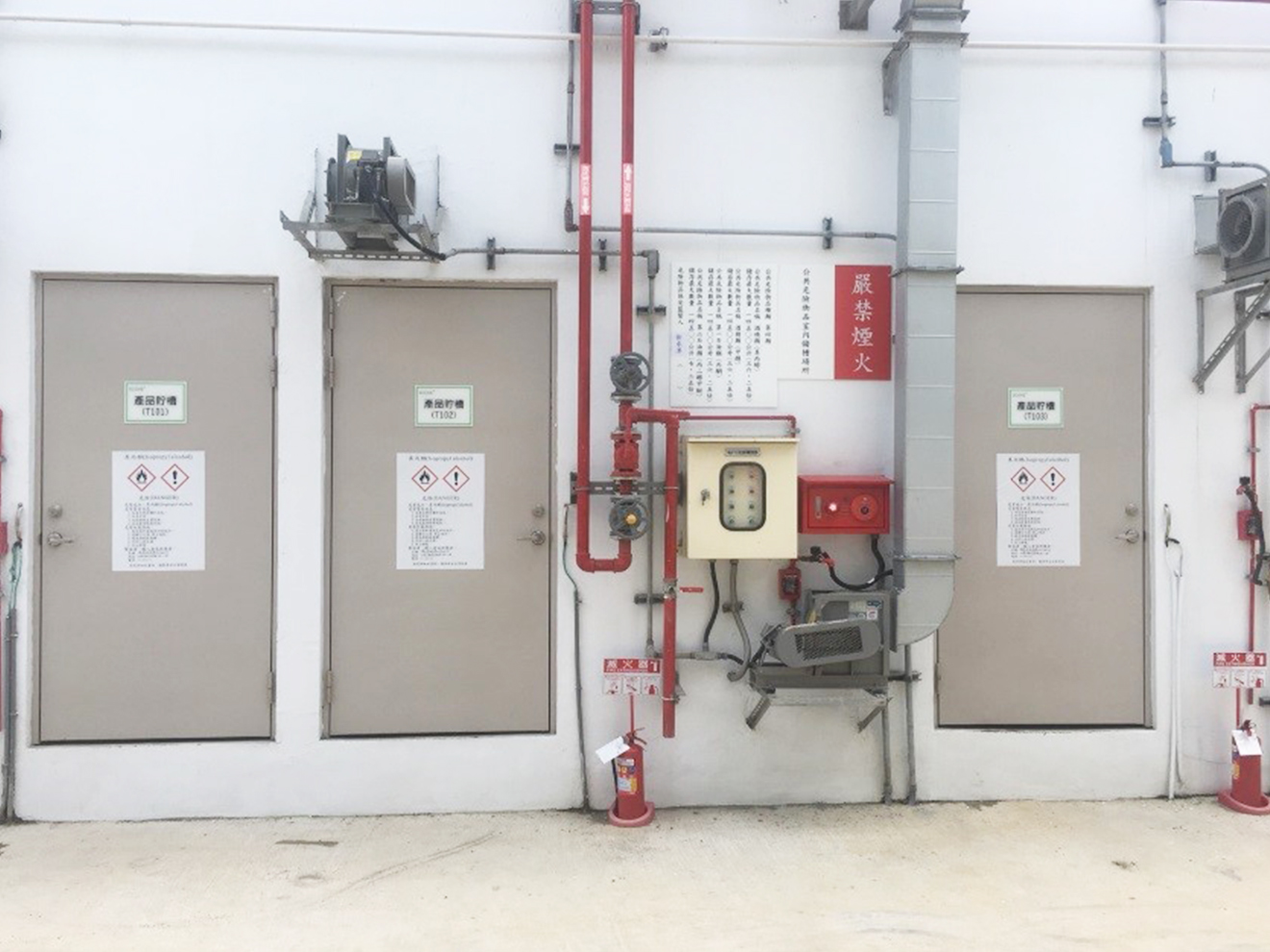

Figure 1. The outdoor scene of ECOVE Solvent Recycling Corp.

Industrial Safety Comes First Create a Safe Operating Environment

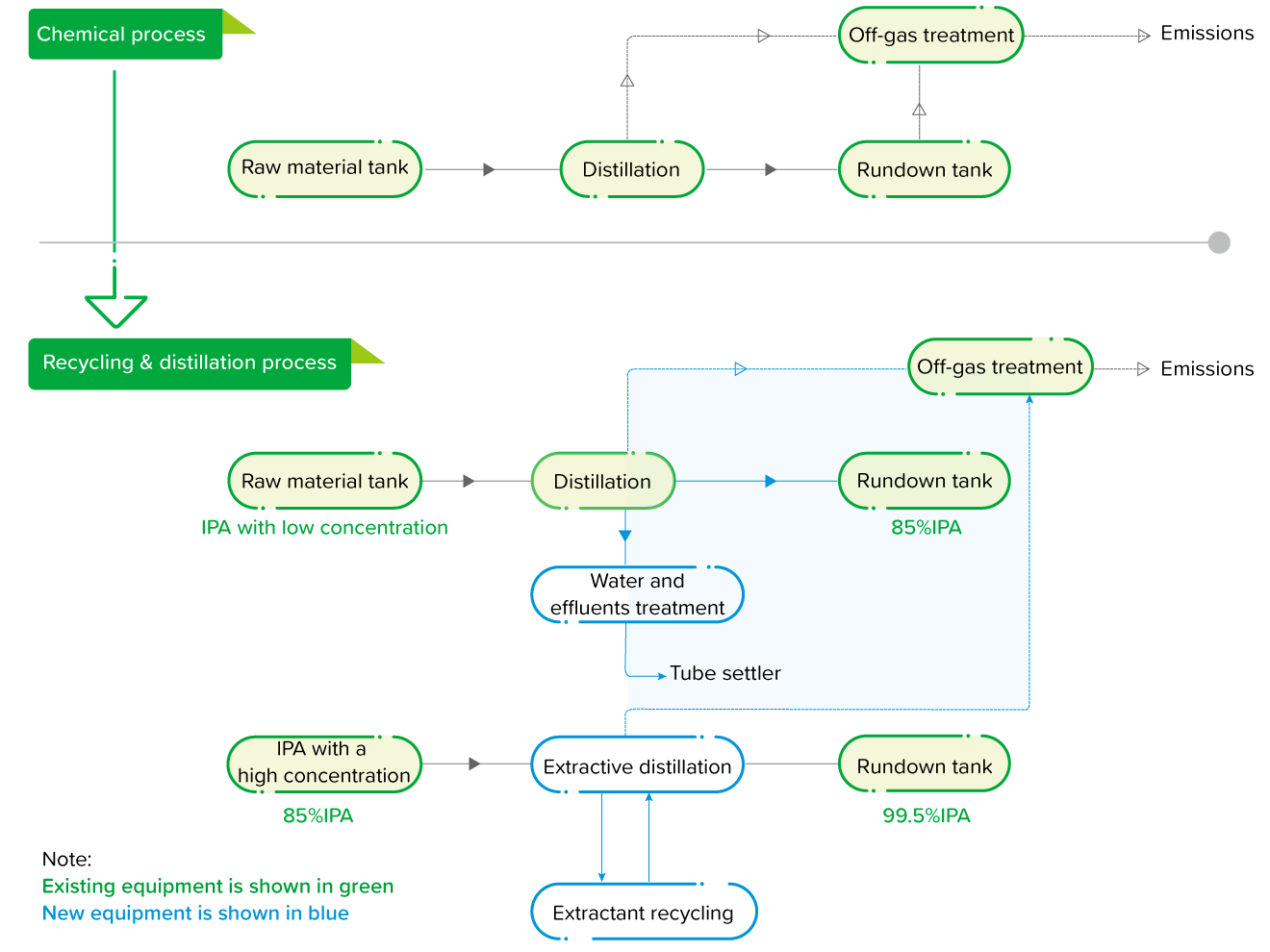

Established by ECOVE, ECOVE Solvent Recycling Corp. mainly works on dewatering and condensing solvents through the original chemical process (e.g. increase isopropyl alcohol concentration from 85% to 99.5%). And now, we combine the reusing process to increase the low concentration of waste isopropyl alcohol (15%) to 85% concentration, making waste isopropyl alcohol become renewable resources.

Figure 2. Waste solvent recycling and reusing process in ECOVE Solvent Recycling Corp.

Due to the complicated composition of waste isopropyl alcohol, its steam and liquid are usually inflammable and explosive, which may cause the tempering if exposed to ignition sources. As the most reliable practitioner of sustainable resource cycling, ECOVE gives priority to fire fighting and safety since ECOVE Solvent Recycling Corp. was established. Through integration and management systems from professional team and applied them to design, reformation and each phase of operations of ECOVE Solvent Recycling Corp.'s plants, ECOVE started Hazard and Operability Study (HAZOP) of safety and firefighting on the entire plant to establish perfect firefighting and safety facilities to closely prevent, reduce and even control hazards (Figure 3). Furthermore, a nitrogen blanketing was added to storage tanks to avoid the effusion of waste isopropyl alcohol with air. The design aims at preventing any harm from the environment and human health by filling nitrogen in storage facilities to form an inert gas cover and combining with a water seal system to prevent effusion and diffusion of Isopropyl alcohol steam(Figure 4). Besides, VOCs, a kind of air pollutant will be generated from the distillation process for waste isopropyl alcohol. Considering that, ECOVE introduced pollution control equipment and constructed it with a combination of activated carbon adsorption and scrubbing towers. Because scrubbing towers and process equipment for waste isopropyl alcohol produce effluents, we redesigned and re-set the sewage treatment system so as to properly prevent the pollution and create a friendly and safe working environment based on the integration of process equipment and pollution prevention facilities. In terms of personnel practice, special training is launched by ECOVE to strengthen employees’ safety awareness and keep the loss and damage to the minimum, which covers emergency management related to about natural disasters, contingencies and safety concerns that may occur during operation.

Figure 3. Product storage tanks were constructed based on the explosion-proof specifications.

Figure 4. A nitrogen blanketing was installed for safety reasons.

Figure 5. Emergency measures of leakage and instructions of protective equipment.

ECOVE Optimizes Cycling Efficiency by Intelligent Management

ECOVE, known as a Taiwan leading brand in the resource cycling industry, has expected the global trend of intelligent management therefore already implemented it internally. The integrated intelligent monitoring and early warning system are used in three main business areas, including Energy from Waste (EfW), solar power and recycling and reusing to improve the operating efficiency. As ECOVE Solvent Recycling Corp. was founded, ECOVE introduced a self-developed maintenance management information system (MMIS) to integrate the big data of material management, equipment maintenance, man-hour management, purchase progress, warehouse management, etc. With the management purpose for waste isopropyl alcohol inbound and purified isopropyl alcohol outbound to increase the operational stability of equipment in ECOVE Solvent Recycling Corp.'s plants. “Recycling resources and turning waste into renewable resources” is the core of the circular economy. ECOVE has engaged in the incineration power plants operation and waste disposal for over 20 years. On the basis of operation and reformation experience of incineration plants, we optimized the equipment and systems of distillation separation of waste solvents, improving the reusing process of waste solvents, while increasing the "resource cycling" efficiency™. In the future, ECOVE will strive to broaden expertise in waste management, introduce state-of-the-art technologies for converting waste into renewable resources and put the philosophy of resource cycling and reuse into practice in order to slow down resource consumption and sustain our natural environment.