Outlook

趨勢展望

ECOVE Puts Circular Economy into Practice & Promotes Resource Cycling

ECOVE operates under three main business, including Energy from Waste (EfW), solar power as well as recycling and reusing. By incorporating the circular economy and sustainable innovation into the foregoing business areas, ECOVE endeavors to build the circular economy that featured " sustainable resources" for Taiwan.

ECOVE Innovates Resource Cycling Business Model

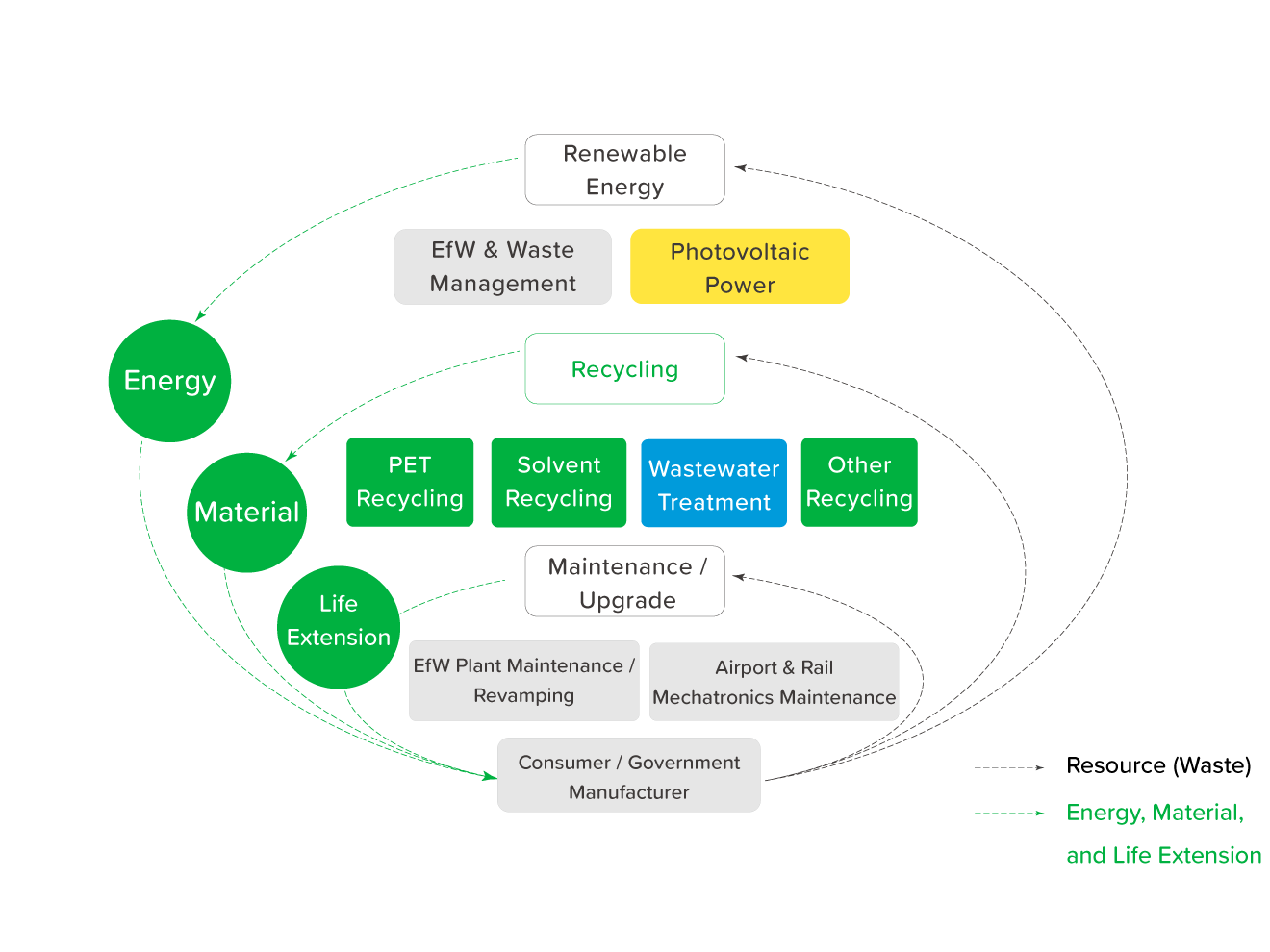

The traditional linear economy is carried out based on the model of "exploration, manufacture, utilization, and discarding". Its large consumption generates massive waste, causing fast exhaustion of raw materials. On the contrary, "circular economy" is the economy and industry system that resources are recoverable and renewable, it attaches great importance to resource utilization efficiency and manages to create greater value with fewer resources to ensure limited resources on earth can be utilized in a renewable and sustainable manner. ECOVE realized the earth resources are limited and hard-earned. Given this, we insist on converting waste into resources while we optimize "resource cycling" efficiency™ and develop an innovative business model of the circular economy through integration and application of intelligent big data management and sophisticated technologies (shown in Figure 1). Among them, for the "maintenance/updates cycle" part, ECOVE strives to extend the service life of the equipment to cut down expenditures for proprietors building new plants and setting new equipment. Such a goal is achieved by reforming incineration plants, maintaining electromechanical equipment in airports and rail stations. ECOVE also promotes the "energy regeneration cycle" through the Energy from Waste (EfW) and the installation of photovoltaic panels. And for the "recycling and reusing cycle" part, ECOVE recycles PET bottles and turns them into chemical fiber materials while purifying wastewater into industrial water. ECOVE also has the key technologies for waste solvents concentration to bring the waste solvents back to the supply chain market as industrial raw materials in order to decrease the depletion of petrochemical raw materials and resources on earth. Our business hits the mark of circular economy initiated globally, which has a positive impact on resource cycling and environmentally sustainable development. ECOVE becomes the first company awarded with BS8001 verification.

Figure 1. Business model and approach of circular economy in ECOVE.

ECOVE Optimizes Resource Cycling" Efficiency™

Taking the area of Energy from Waste (EfW), ECOVE has been engaged in incineration plant operation and waste management with more than 20 years of accumulated experience. By now, we provide services, including commissioning, operation & maintenance, overhaul, revamping and upgrade system and equipment for over two-thirds of 24 municipal incineration plants running in Taiwan. With the successful experience and professional expertise in the operation and maintenance of incineration plants, intelligent data management, equipment upgrade, etc. ECOVE successively acquires patents for many new technologies and applies o plants at home and abroad. Take Macau Refuse Incineration Plant for instance, (shown in Figure 2), it has been operating up to 27 years so far. With the support of maintenance/ updates, ECOVE successfully extended the equipment’s service life of the incineration plant, maintained stable operation, and improved the electricity generation efficiency of the incineration plant. Upon these solutions, electricity per waste is increased by over 20%, which maximizes the efficiency of waste per ton, making it one of the successful cases in resource cycling.

Figure 2. Macau Refuse Incineration Plant greatly increases electricity generation efficiency of incineration plants under the operation of ECOVE.

By upholding the fulfillment of circular economy concept, ECOVE then applies the technologies to electromechanical services and rail transportation, which covers public transportation system, such as Kaohsiung MRT, Taipei MRT and Taoyuan Airport MRT as well as large-scale public facilities, such as hospitals and international airports to provide services, including operation and maintenance of equipment in plants and sites, testing on railway system, etc. ECOVE does proper equipment maintenance daily to extend service life and assists the mass transportation system and national airports for their stable operation, providing safe means of public transportation for the public.

ECOVE Implements Corporation Social Responsibilities

Taiwan, the major manufacture base of semiconductor in the world, produces various forms of industrial wastes every year during the manufacturing processes, such as solid, sludge, solvents, acid-base matters and other liquids. Being as a circular economy practitioner, ECOVE is devoted to research technologies that can convert waste into recoverable matters. In 2018, ECOVE established ECOVE Solvent Recycling Corporation. It is expected to recycle over 6,000 tons of waste solvents every year in the future and turn them into the industrial raw materials through the concentration process, bringing the recycled products back to supply chain markets. Meanwhile, over 5,000 tons of carbon dioxide emissions, equaling to the annual carbon absorption of 13 Da’an Forest Parks, will be reduced every year. This is the contribution ECOVE makes to the topic of responsible consumers and the production cycle. In terms of PET bottle reuse, ECOVE picks PET bottles out from the original path of the incineration process and produces functional fibers after washing and slicing to make high-tech functional clothes, making it a specific contribution to reducing dependence on petrochemical raw materials and the relevant usage amount. Moreover, ECOVE assisted the Macau government to convert food waste into resources recently. Food waste should have been burned away in incineration plants, but now they can be converted into absorbable plant fertilizers with new technologies, turning organic waste into valuable organic fertilizers back to earth in the manner of a circular economy with success.

Figure 4. Cooked food waste (left) became organic fertilizers (middle) after the new technical process. The packed organic fertilizers were sent to civilians in Macao for use (right).

ECOVE started its development of a circular economy from Energy-from-Waste (EfW) and waste management, which are embodied in the innovative circular economy of resource recycling, substance recycling, and value-added reuse, sprung from the model of “extending life cycle, re-manufacture and reuse". ECOVE looks forward to constantly introducing new technologies in the foreseeable future to offer highly efficient resource management services with the integration of technologies to reuse wastes, builds a sustainable country that can provide energy, clean water, and sanitation and become the most reliable provider of industry-leading ‘resource cycling’ services.