Key Technology

關鍵技術

A Case Study of Smart O&M for Water Treatment at Linkou Water Resource Recycling Center

Linkou Water Resource Recycling Center (Linkou Center) is the first class-2 sewage treatment plant built and operated by the New Taipei City Government, which has been in operation for more than 10 years. In 2018, ECOVE became the operation and maintenance (O&M) contractor for the Linkou Center. In addition to rigorously completing all tasks at every stage as required, ECOVE is committed to making technological improvements in water management by referring to smart solution cases at home and abroad. In the end, ECOVE set up an intelligent solution system that features water level and water quality monitoring instruments, as well as data transmission, database construction, and data analysis. This helps it create a smart prototype of sewerage management system for the district, thus allowing Linkou Center to progress from automation towards intelligence solutions, becoming a smart sewage treatment plant.

From Automation to Intelligence Solutions

Water treatment systems face complicated problems during operations and maintenance. Most of the existing water treatment systems are equipped with programmable logic controllers (PLC) that aim to achieve "automatic" equipment operations, yet in fact, such systems still rely on human judgments and manual adjustments. Currently, many efforts at home and abroad have been geared to finding intelligent solutions for operating water treatment systems in order to minimize the differences in human judgements as well as raising the quality of operation management. The hope is to use smart technologies to help achieve optimal adjustment in real time, such as by installing sensor instruments to existing systems and equipment, collecting data, and making model analyses. As Linkou District has grown rapidly over the years, the amount of wastewater has increased. With better and convenient technologies, Linkou Center’s operational efficacy has improved, allowing it to play an increasingly important role. The center primarily collects wastewater from households through 9 wastewater lift stations (Figure 1). A lift station serves to raise the level of water that is flowing in a waterway. To improve O&M efficiency, ECOVE continues to optimize and introduce a number of application systems. One example is the "electronic inspection system," which allows staff to send inspection records to the management center in real time. By real time it means the team can immediately know the equipment conditions and carry out analyses, thus improving inspection efficiency. Another example is the Maintenance Management Information System (MMIS), which is developed by ECOVE. This system can help arrange maintenance schedules based on equipment conditions and ensure the availability of equipment. Moreover, it allows all operations become truly digitalized, real-time, and paperless.

Figure 1. Distribution map of wastewater lift stations in Linkou.

Other notable examples of smart solutions for lift stations include intelligent pipeline network monitoring, automatic dosing, and intelligent diagnosis solutions for rotating equipment. The intelligent pipeline network system’s purpose is to allow the team to analyze the trends and changes of flow volume to help better control equipment at lift stations. The reason is that the amount of domestic wastewater differ greatly at peak hours and off-peak hours, and it is critical to ensure a stable inflow of wastewater to maximize the effectiveness of the water treatment system in the center. To this end, ECOVE looked up cases abroad and carried out an aggressive assessment on designing such system in Linkou District. Before the days of intelligent pipeline network analysis, pipeline network analysis was commonly used for tap water supply system. It aids the management and maintenance of the water distribution pipelines by providing predictions on the changes in water pressure, flow volume, and water quality in the pipeline network of the water supply area. In recent years, it has also been applied to sewerage systems to help design and control inlet or outlet piping. However, due to factors such as the diameter of sewerage pipelines, the means of inflow, the difference in horsepower of power transmission equipment, and the impact of extreme weather due to climate change, most of these systems can only set conditions for control using formulas and PLC. Once we add in an intelligent feature with artificial intelligence, such calculations and analyses can allow room for more complex and diverse adjustments and controls, which brings more efficient results and more stable flows. The following is an overview of Linkou Center’s intelligent pipeline network monitoring system at lift stations, automatic dosing system, and intelligent diagnosis solutions for rotating equipment.

Intelligent Pipeline Network Monitoring System for Wastewater Lift Stations

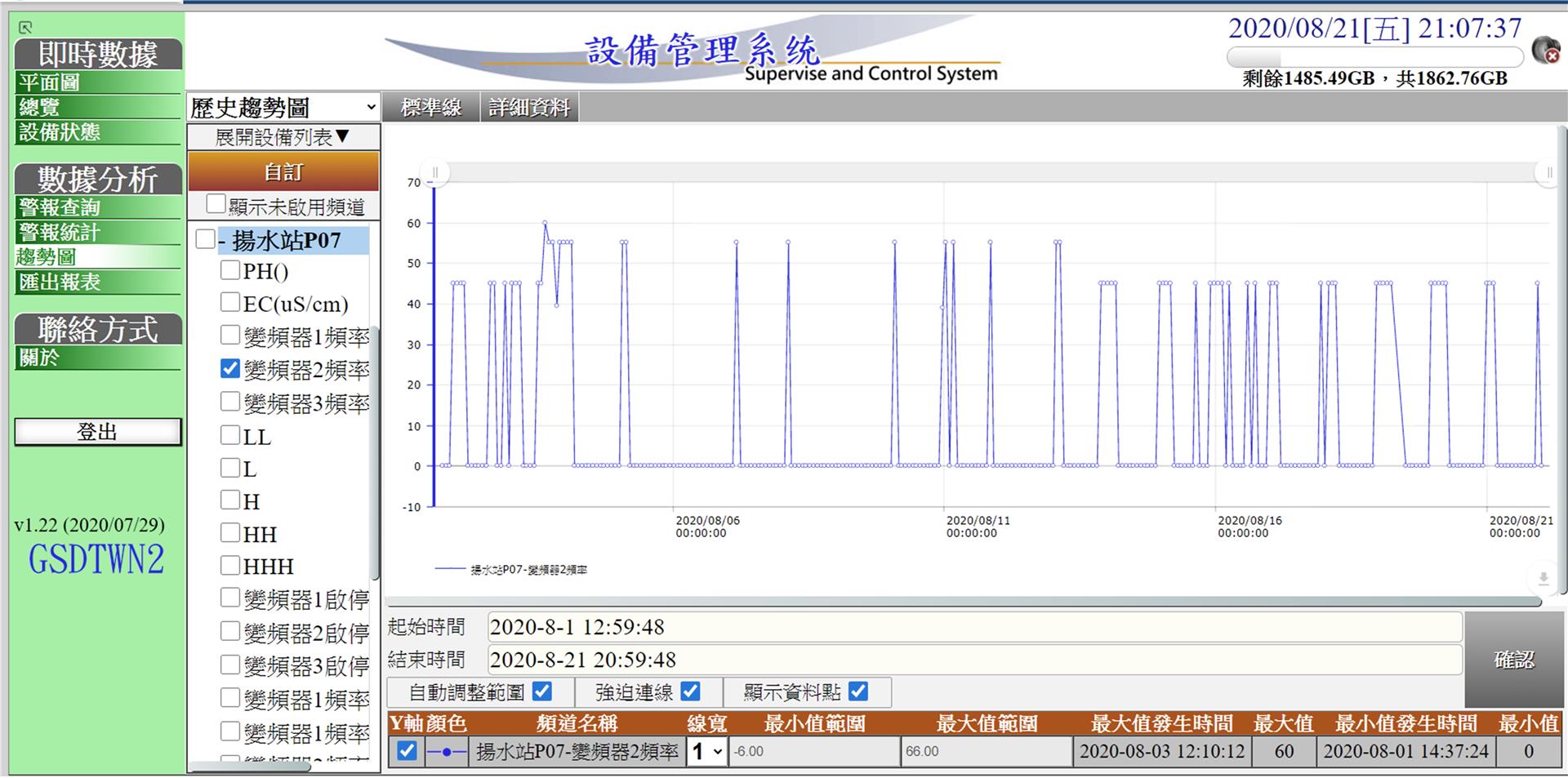

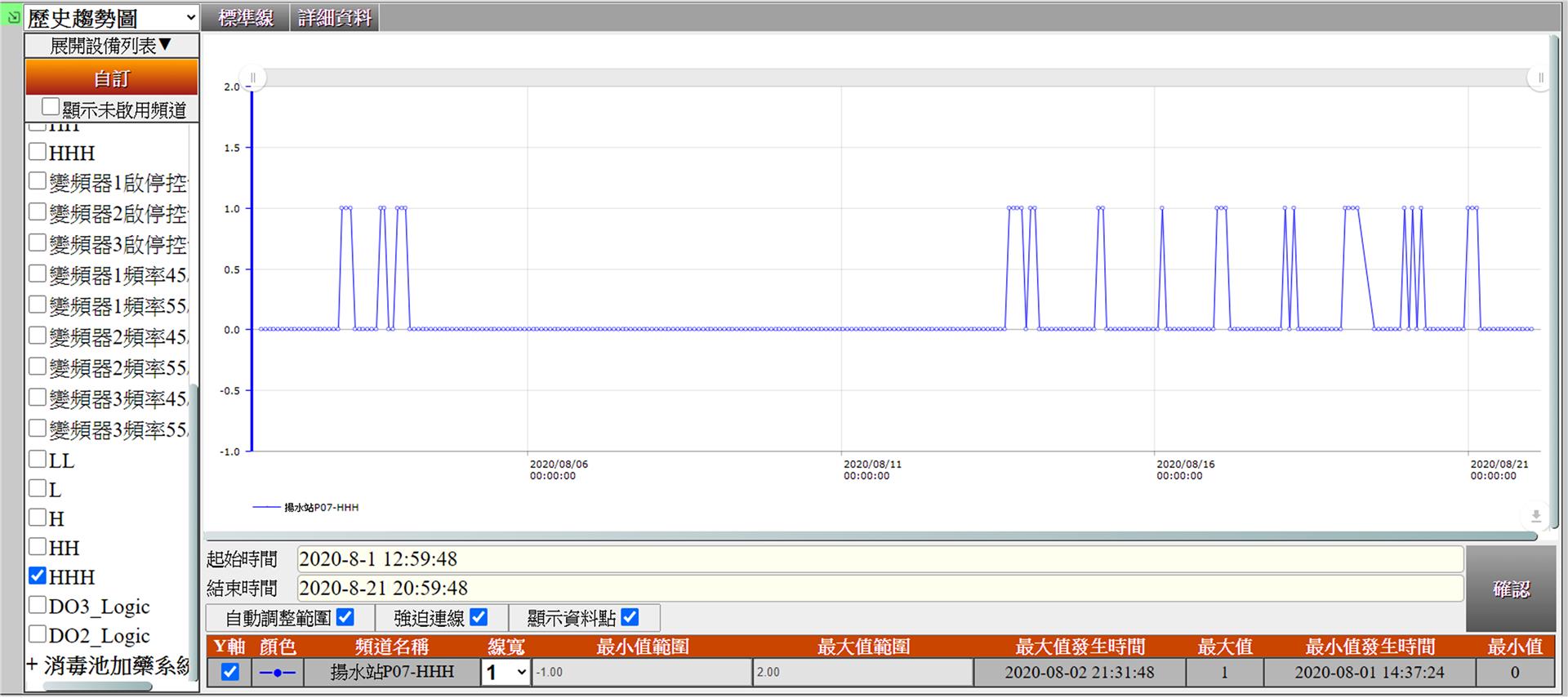

The wastewater lift station is an important part of the sewerage pipeline network. To achieve better management, ECOVE made a pipeline network monitoring system in Linkou and installed sensor instruments (for water level, water volume, water quality detections, etc.) Then ECOVE takes the data fed back from these instruments and rainfall forecasts for further analysis on the parameters of the pipeline network. This serves as reference for operation management to decide when to reduce the peak load of the center's sewage inflow, when to increase the off-peak load, so that the center's load capacity and the operational stability of the system can be increased. The system also allows the center to have a real-time understanding on the water levels at wastewater lift stations, which can be used as a reference for decision-making in disaster prevention preparations and help strengthen disaster response capabilities. Currently, the system for the primary wastewater lift station P07 has been completed. The overall inflow volume from pumps makes up 70% of overall inflow volume of this site. The monitoring system monitors the sensor instruments such as those for water level and water quality and equipment operation status. The system transmits monitoring data through 3G SIM card IoT module and remotely monitors the operation status of the pumps at the wastewater lift stations. Once the entire intelligent pipeline network monitoring system for the lift stations in Linkou District is completed, it is expected to bring benefits such as stable wastewater inflow, stable operation of equipment, energy conservation, prolonged equipment life cycle, among others.

Figure 2. Graphical monitoring screen.

Figure 3. Equipment operation trends chart.

Figure 4. Water level trends chart.

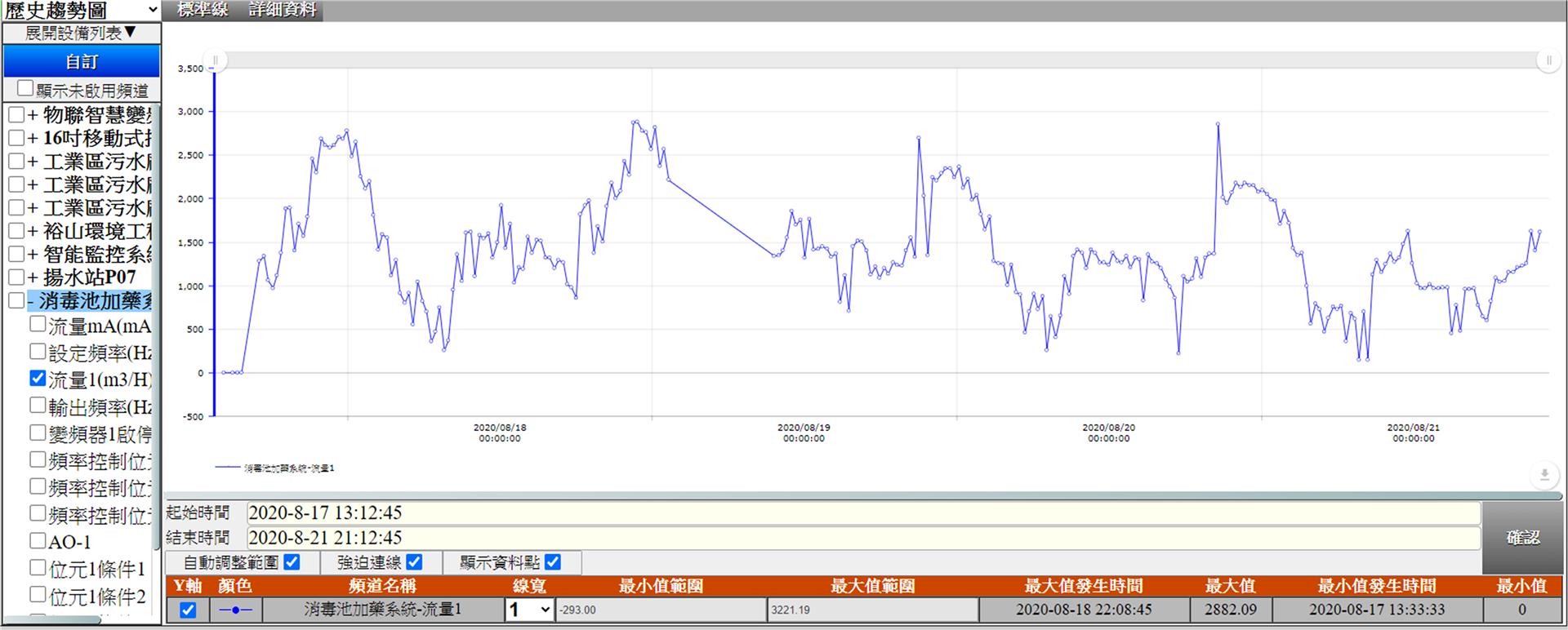

Automatic Dosing Control System

Chlorination is one common and indispensable process of treating wastewater. As soon as ECOVE took over Linkou Center, the company began to work on the automatic dosing control system. The new control system uses instruments and cloud data computing to replace manual dosing, which allows the dosing process to be optimized and no chemical would go wasted. In the past, due to equipment constraints, the dosage level could only be determined with lab test results and the operator’s experience, and could not allow real time dosage adjustments, which often led to over-dosage. Now, with an automatic dosing control system in place, such problem is solved, taking the center a step closer to becoming an intelligent water treatment plant.

Figure 5. Graphical monitoring screen.

Figure 6. Flow volume trends chart.

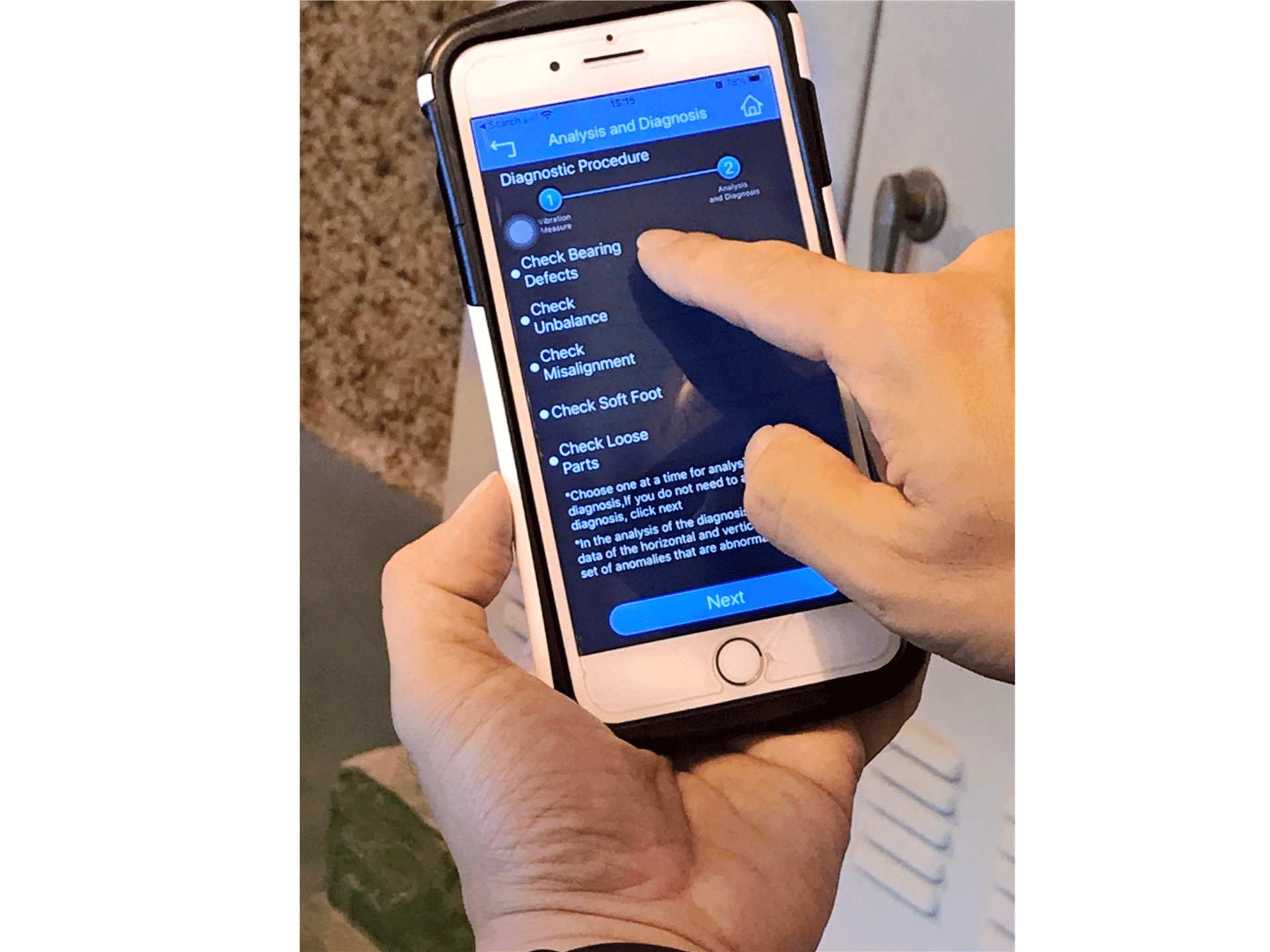

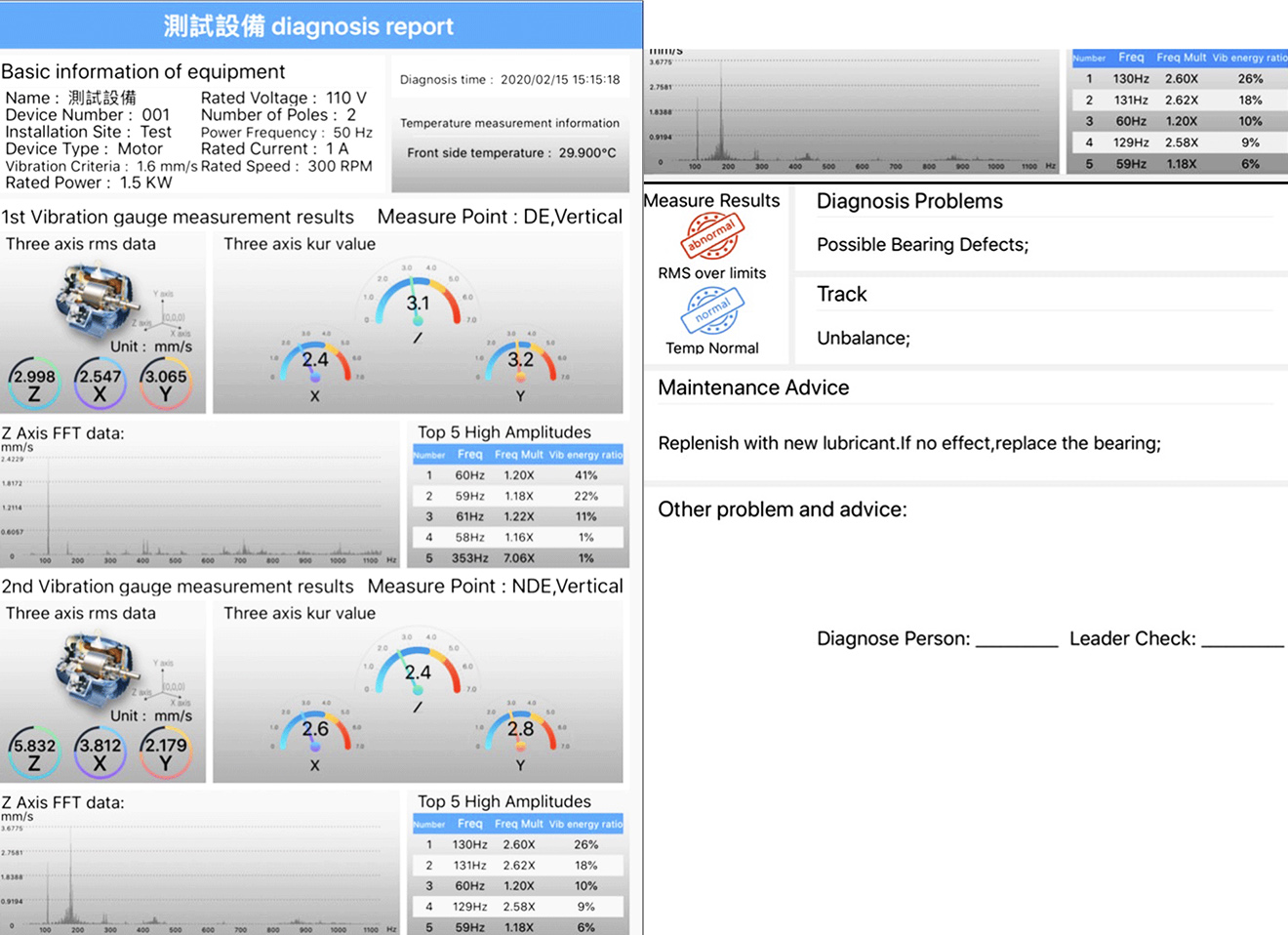

Intelligent Diagnosis Solutions for Rotating Equipment

Linkou Center relies on power equipment to maintain high treatment efficiency and high quality of discharged water. Such power equipment are mostly rotating equipment. In the past, maintenance was conducted in accordance with the maintenance schedule recommended by the vendors, while repairs were only conducted when there was an apparent malfunction. In actual practice, however, malfunctions can be foreseen before they occur. For example, diagnoses can be conducted by analyzing the vibration. But these diagnostic analyses are time-consuming, labor-intensive, and require experienced mechanical engineers, producing limited effectiveness. To this end, ECOVE has introduced an intelligent diagnosis solution for rotating equipment in the center to aid judgment. This system not only measures the vibration of the equipment, but also analyzes the historic diagnostic data through the cloud system, and generates a diagnostic report to serve as a reference for equipment maintenance. By arranging preventive maintenance for equipment that have been diagnosed as equipment subject to a risk, the goal of predictive maintenance and prolonged equipment life cycle can be achieved.

Figure 7. The result of real-time rotating equipment diagnostic analysis.

Figure 8. The rotating equipment diagnostic analysis report.

To realize the vision of an intelligent water treatment plant, ECOVE will continue to refine its intelligent solutions application at Linkou Center with intelligent solutions systems and data management. The company will also support the development and recycling of global water resources with concrete actions, and respond to the “clean water and sanitation” goal as dictated in the United Nations’ sustainable development goals. By living up to the ideal of "Every Resource Counts," ECOVE is, and continues to be, the most reliable provider of industry-leading “resource cycling” services.