Innovation

企業創新

ECOVE Continuously Implements Blood Dioxin Tracking and Testing to Safeguard the Health of Employees

We at ECOVE respect employees as the company's biggest asset. Not only has the company invested resources to establish a safe and worry-free work environment, but we have also commissioned the Research Center of Environmental Trace Toxic Substances at National Cheng Kung University (NCKU) to conduct blood dioxin monitoring since 2008. Employees who work in incineration plants are categorized based on their work environment, exposure time, and years of work. Representative workers from the categories are then selected for blood dioxin level monitoring. Every four years, blood is taken from the selected employees for follow-up testing and tracking. The fourth test was conducted at the end of last year (2020). We are not only the first company in Taiwan to monitor the blood dioxin level for our incineration plant workers, but are also one of the very few companies in the world to continuously track, analyze, and study dioxin levels in workers.

Implementing Blood Testing, Tracking, and Management Measures to Safeguard the Health of Employees

We conducted the fourth round of blood dioxin testing and tracking at the end of 2020 of our employees. During the testing, doctors also conducted a survey on the health, diet, and work exposure of employees, and these were used for making a cross-comparison. Related health advocacy and care were also offered to the workers. The test results came out in February 2021, and it showed that the dioxin concentration in the blood samples of ECOVE employees was lower than that of the average person in Taiwan and at the level recommended by the World Health Organization. This result showed that the incineration plants operated and managed by ECOVE had comprehensive and effective air pollution prevention equipment and management mechanisms, which are able to collect, break down, and remove dioxin. These equipment and mechanisms supplement the automated incineration control technology, which strictly monitors and controls burning temperature, retention time, CO concentration, as well as oxygen content to reduce or prevent the generation of dioxin. Furthermore, ECOVE has implemented employee health and safety training and other related management and prevention measures to safeguard their health.

Test Results and Analysis

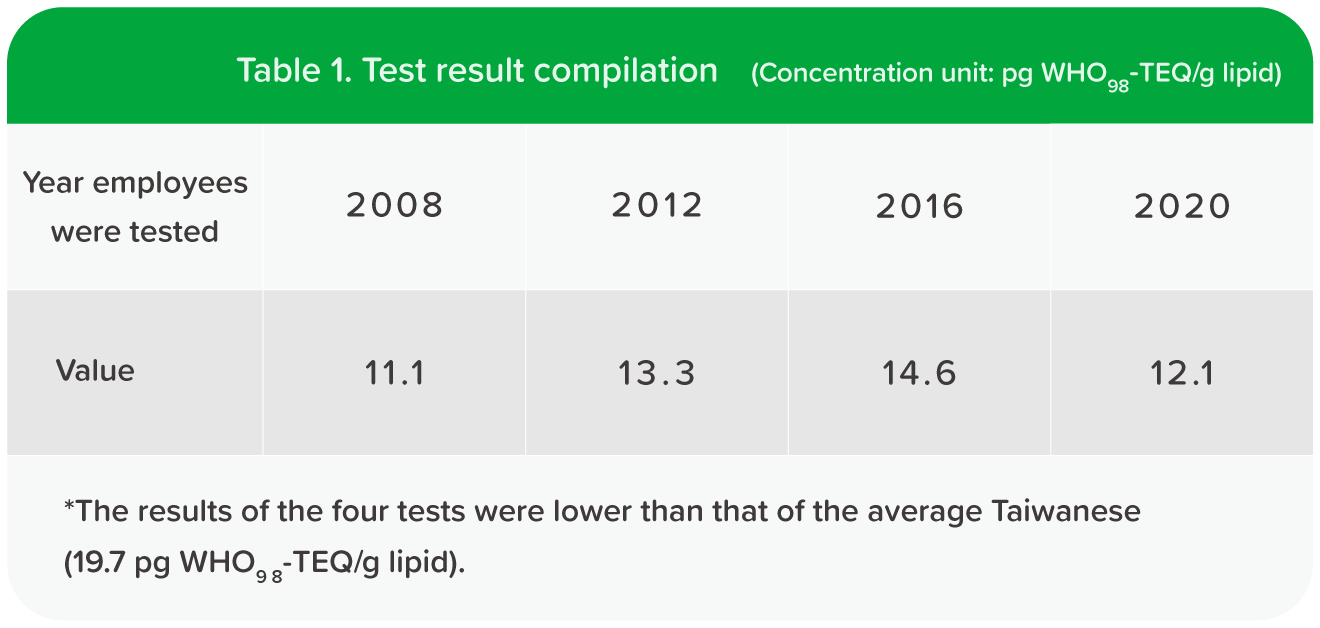

ECOVE places high emphasis on blood dioxin tests. For this test, 38 employees were selected (although there were employee changes due to reassignment, resignation, and retirement, there were still 13 people who have participated in all four tests). Test items include sampling and analysis of 17 types of polychlorinated dibenzo-p-dioxins (PCDDs)/polychlorinated dibenzo-p-furans (PCDFs) in the blood of employees, 14 biochemical testing items, a survey of the health, diet, and work hours of operating personnel, and compilation/analysis of the data. The test results for this round of tracking are shown in Table 1, which included all waste incinerator site workers in ECOVE operated plants across Taiwan. The data showed that the average blood dioxin concentration level was 12.1 pg WHO9 8 -TEQ/g lipid, which was lower than the 19.7(3.4-89.2) pg WHO9 8- TEQ/g lipid of the average Taiwanese . This goes to show that although the incinerator operators have been working in the incinerator for a long time, there was no increase in the blood dioxin concentration.

Table 1. Test result compilation

ECOVE's Prevention and Management

Dioxins are colorless, odorless, and highly toxic lipophilic chemicals that can be stored stably in animal lipids. Thus, it has been known as the "poison of the century." Because of the dangers dioxin poses to the human body and to the environment, the emission monitoring values of the incineration plants managed by ECOVE are similar to that of Europe, the United States, and Japan, in order to avoid dioxin generation caused by incomplete combustion. In addition, ECOVE boasts excellent management and prevention measures that effectively prevent dioxin from entering the human body, including:

- Implementing waste incinerator combustion temperature monitoring and control (a combustion temperature higher than 850℃ will destroy dioxin).

- Utilizing intelligent management to establish a comprehensive maintenance plan, adequately maintaining waste gas emission pollution prevention equipment, and allowing waste gas emission and pollution prevention equipment to operate 24 hours a day without interruption.

- Providing sufficient and effective personal protective equipment (PPE) such as protective clothing, N95 masks, and half-cover gas masks. Workers and contractors are strictly required to wear the PPE in high-risk exposure areas. Compliance is ensured through on-site patrolling and audits.

- Setting up washing facilities for workers to shower immediately after work. This lowers the body's contact with dioxin.

- Providing work uniforms and offering centralized laundry washing within the plant. This is to prevent work clothes from being taken home and getting mixed up with home laundry, indirectly causing contamination.

- Regularly organizing employee health checks; Using blood dioxin tests and cross-comparisons to understand whether test values of employees have increased or changed. Professional medical personnel engage with employees to understand the cause of the problem, as well as remind employees to take better care of themselves and track their health at all times.

- Studies show that 90% of human blood dioxin accumulation is caused by food intake. ECOVE regularly hosts health seminars to teach employees how to eat a healthy diet, such as reducing meat and dairy-type lipid intake, and eating high fiber foods like fruits and vegetables. Employees are also taught to wash their hands immediately after smoking and work to prevent the ingestion of dioxins.

We at ECOVE take a serious attitude towards the dangers of dioxin in the worker's environment. To prevent employees from being exposed to environmental dioxin, the Company organizes workplace safety and health training prior to periodical repair work, which is when exposure is at its peak. This training teaches employees how to correctly put on safety and protective equipment. Workplace safety management is also conducted daily, where workers are required to wear protective equipment and inspections are conducted. Managers and supervisors use a "mobile management" supervisory method to strictly implement worker health and safety standards. To us, "giving employees and their families peace of mind; letting there be no concerns about workplace safety and leading a healthy life" has never been just a slogan. It is at the core of what we do, and a commitment to our employees, contractors, and their families. We believe that how our employees and their families feel will eventually be a reflection of the company and will help drive ECOVE's sustainable development.