Key Technology

關鍵技術

Drones with Infrared Cameras Can Help Improve Solar Farm Maintenance

Located in the subtropical zone, Taiwan is blessed with abundant sunlight, making it ideal for developing solar power. ECOVE has years of experience in constructing, operating, and maintaining solar photovoltaic (PV) farms, both in Taiwan and the United Sates. So far, more than 70 PV projects have been connected to grid. This article will discuss how ECOVE uses infrared cameras mounted on drones to improve solar farm inspection, timely detect equipment abnormalities, and raise overall solar power output.

Solar Power Generation in Taiwan: Current Status and Target

Most of the raw materials used for conventional, non-renewable power generation in Taiwan are imported, as the nation has limited resources for such type of power generation. Following a global trend in green energy, Taiwan began pushing for solar power since 2000. The Renewable Energy Development Act (REDA)— the parent law guiding green energy development in Taiwan— was passed in 2009, dictating the Ministry of Economic Affairs to be the central competent authority, while the Bureau of Energy acts as implementer. Under REDA, the target for cumulative installed PV capacity is 20 GW by 2025, accounting for at least 66% of renewable energy. Thanks to the 20-year Feed-In Tariff offered by the government as well as advancement in technologies, solar power installation capacity grew significantly. As of December 2020, total installation capacity reached 5.8 GW. However, installation capacity is only part of the picture. What is equally important is maintaining the functionality of equipment and facilities for solar power generation. In this respect, infrared camera can help operators detect potential problems and improve power generation efficacy.

Using multi-axis drones with infrared cameras to detect problems

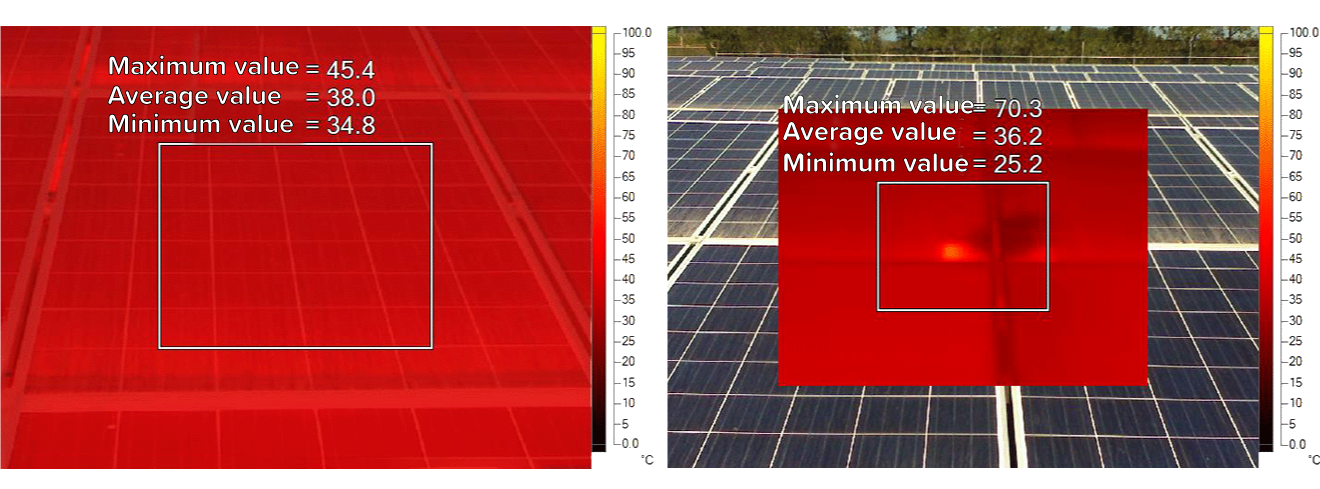

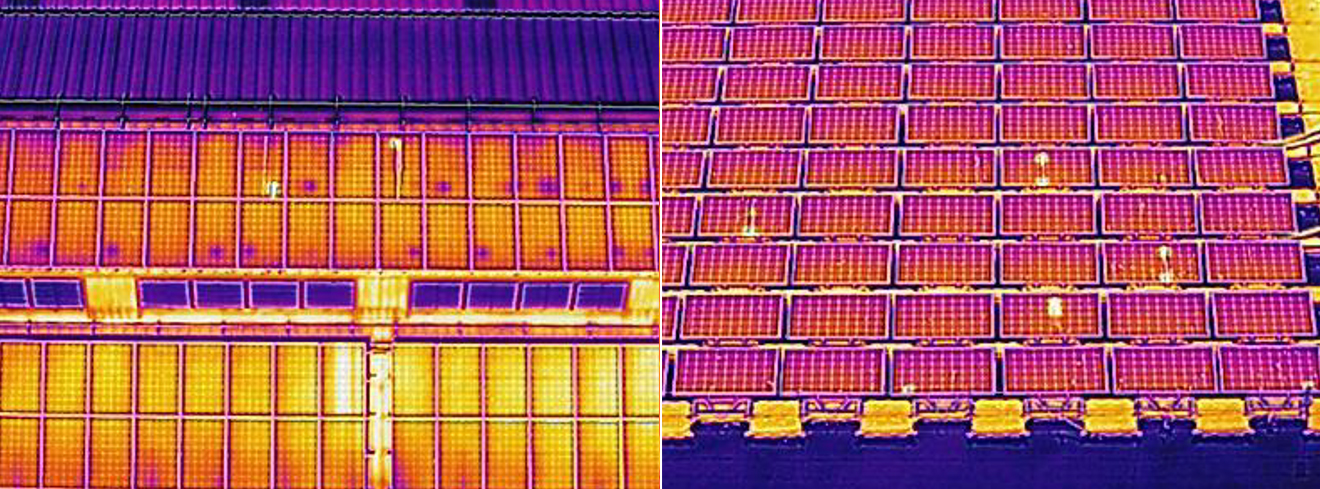

Infrared thermal inspections are conducted with multi-axis drones that have visible light and infrared dual function camera modules. Besides taking thermal images, these modules can also capture synchronized visible-light images, allowing comparison of defective areas to avoid misjudgments and help analyze the causes of defects. Drones can cut 50% of the time needed for manual inspection. Moreover, drones can fly on auto-mode according to preset routes, ensuring each spot to be precisely and repetitively checked, avoiding potential errors by human operations. After each inspection, abnormalities will be recorded in an imagery database for future smart analysis. Inspecting PV modules with conventional handheld thermal cameras suffer from a couple of drawbacks: 1. Inspections can only be done in smaller chunks and in phases (Figure 1). 2. Inspections are inefficient, can miss out some parts, and the results cannot be accurately interpreted.

Figure 1 PV modules seen through handheld thermal cameras.

Due to these drawbacks, all of the solar farms operated by ECOVE are examined and maintained through thermal images taken by infrared cameras mounted on multi-axis drones (Figure 2). With an aerial view, we can overcome terrain challenges, conveniently and swiftly spot abnormal PV modules by screening larger areas at fixed height and versatile lens angles. These drones are also widely applied to all sorts of thermal-related studies or inspections due to their unique perspectives.

Examples of abnormality inspections

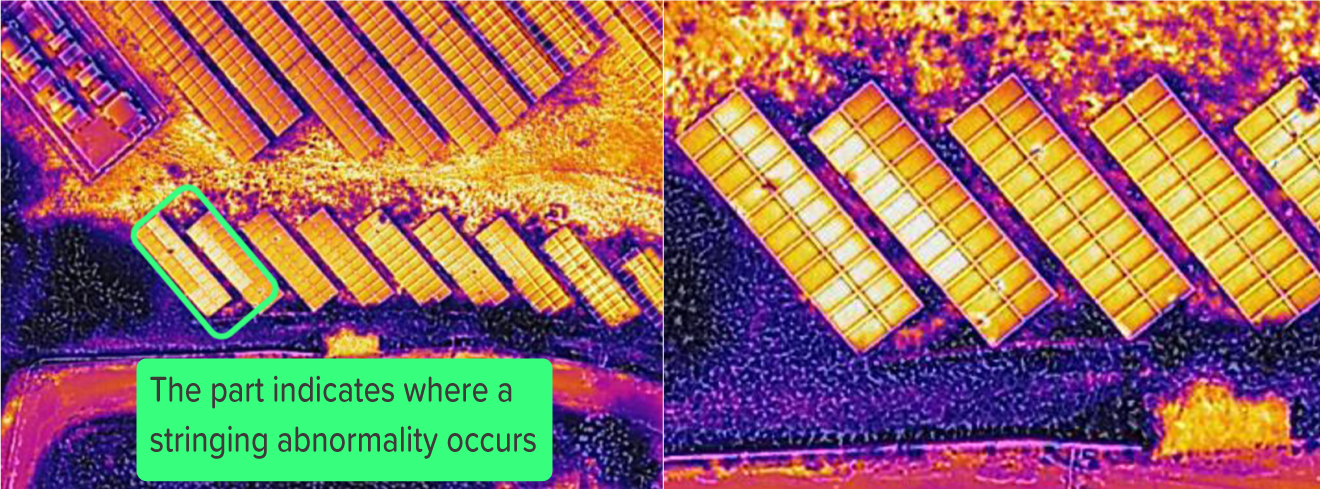

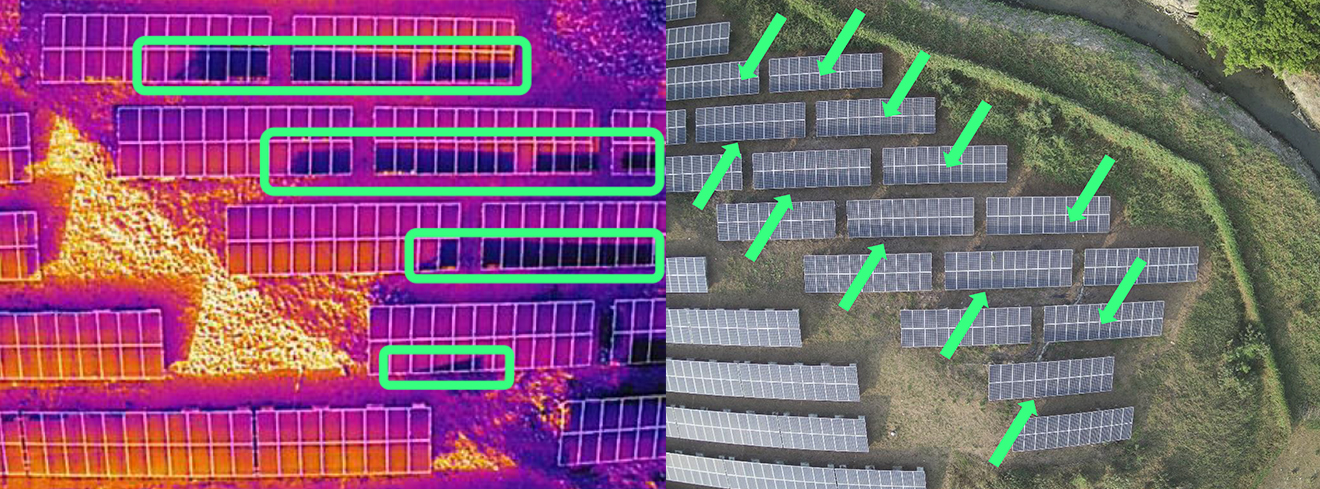

Because multi-axis drones can conduct large-scale inspections at designated height, they can quickly and accurately spot larger spans of abnormalities, thereby enhancing inspection efficacy. The following are some examples of the abnormalities detected with infrared cameras mounted on drones. 1. Stringing abnormality (Figure 3) This type of abnormality is not easy to detect from the ground with manual inspection. Moreover, it does not generally pose severe impact on power generation in a larger farm, so unless string monitoring devices are installed, such abnormality is hard to detect.

Figure 3 Thermal image of PV modules where a stringing abnormality occurs.

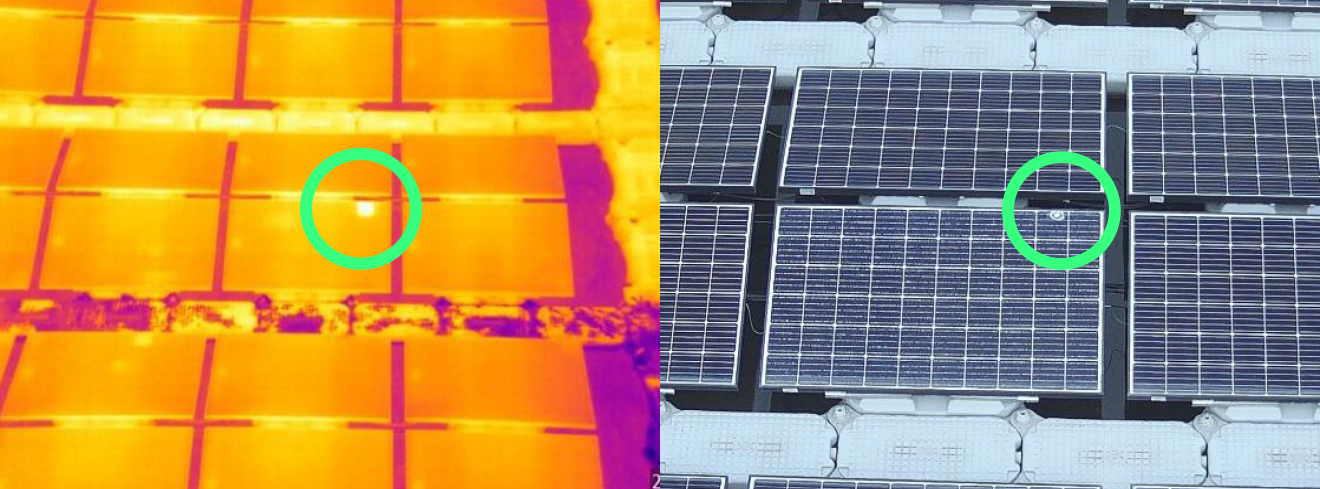

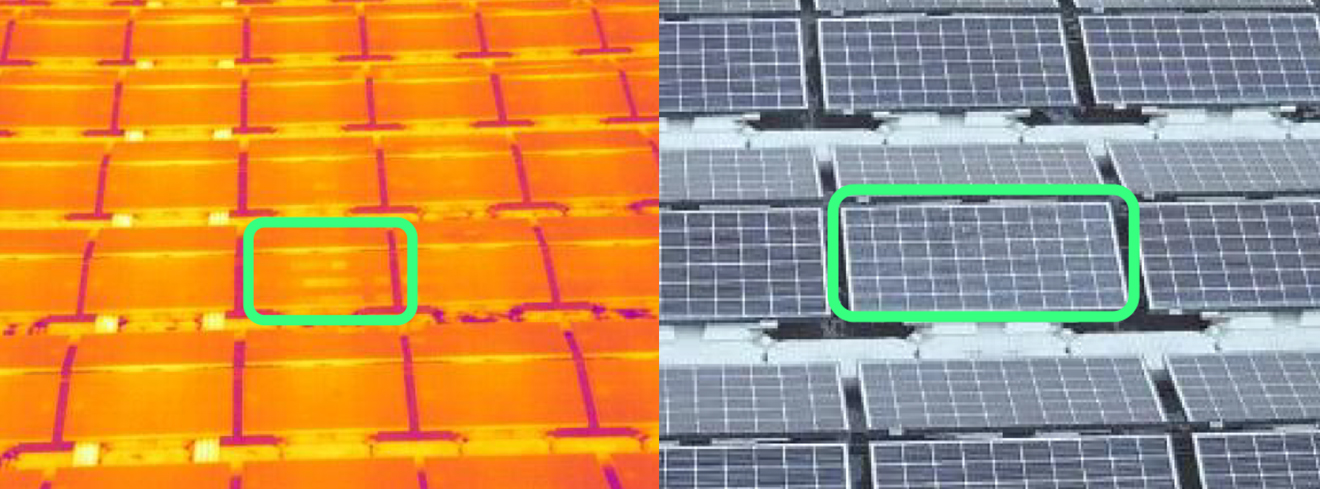

2. Cracked PV modules (Figure 4 and 5) This is one of the most common abnormalities seen on solar farms. With drones, cracks can be quickly spotted.

Figure 4 Thermal images of cracked PV modules.

Figure 5 Thermal images of cracked PV modules.

3. Module stain/shading This is also a major factor that affects power generation. Stains include biological stains and environmental shading. Thermal images taken by drones are a fast way to determine the type of stain or shading (Figure 6 and 7). Combined with the farm’s power generation data, one can effectively evaluate and conduct module cleaning and vegetation removal. Environmental shading can also be used for simulation data comparisons for subsequent farm constructions.

Figure 6 Thermal images indicating biological stains.

Figure 7 Thermal images indicating PV module shadowing.

Conclusion

As solar power increasingly plays a major role in renewable energy output, it is critical that solar farm inspections be carried out effectively. With a mission to “improve technological integration and applications, as well as optimize resource cycling efficiency,” ECOVE will keep improving its technologies to ensure power is generated efficiently on solar PV farms. It will also implement circular economy and help the government gradually reach energy transition and energy diversification targets, ushering in a low-carbon future for Taiwan.