Key Technology

關鍵技術

Optimizing Combustion Quality and Reducing Carbon Emissions: ECOVE’s Advanced EfW Plant Solution for Airport Waste

For more than a decade, ECOVE Environment Corporation (ECOVE) has been the operation and maintenance (O&M) contractor for Taoyuan International Airport Incineration Plant (TIAIP), an Energy-from-Waste plant responsible for treating waste generated at the airport. Through sound management and overall solution provision, ECOVE has effectively improved TIAIP’s operation performance. Waste combustion reaches higher quality, while fuel consumption is reduced. Overall, disposal capacity has increased from 4,700 tons to 11,000 tons per year to cope with the amount of waste forecast to grow due to surging passenger volume at Taoyuan International Airport, a major gateway to Taiwan. Consequently, ECOVE has greatly enhanced energy conservation and reduced carbon emissions.

Total solutions provider: Optimizing combustion system to improve efficiency

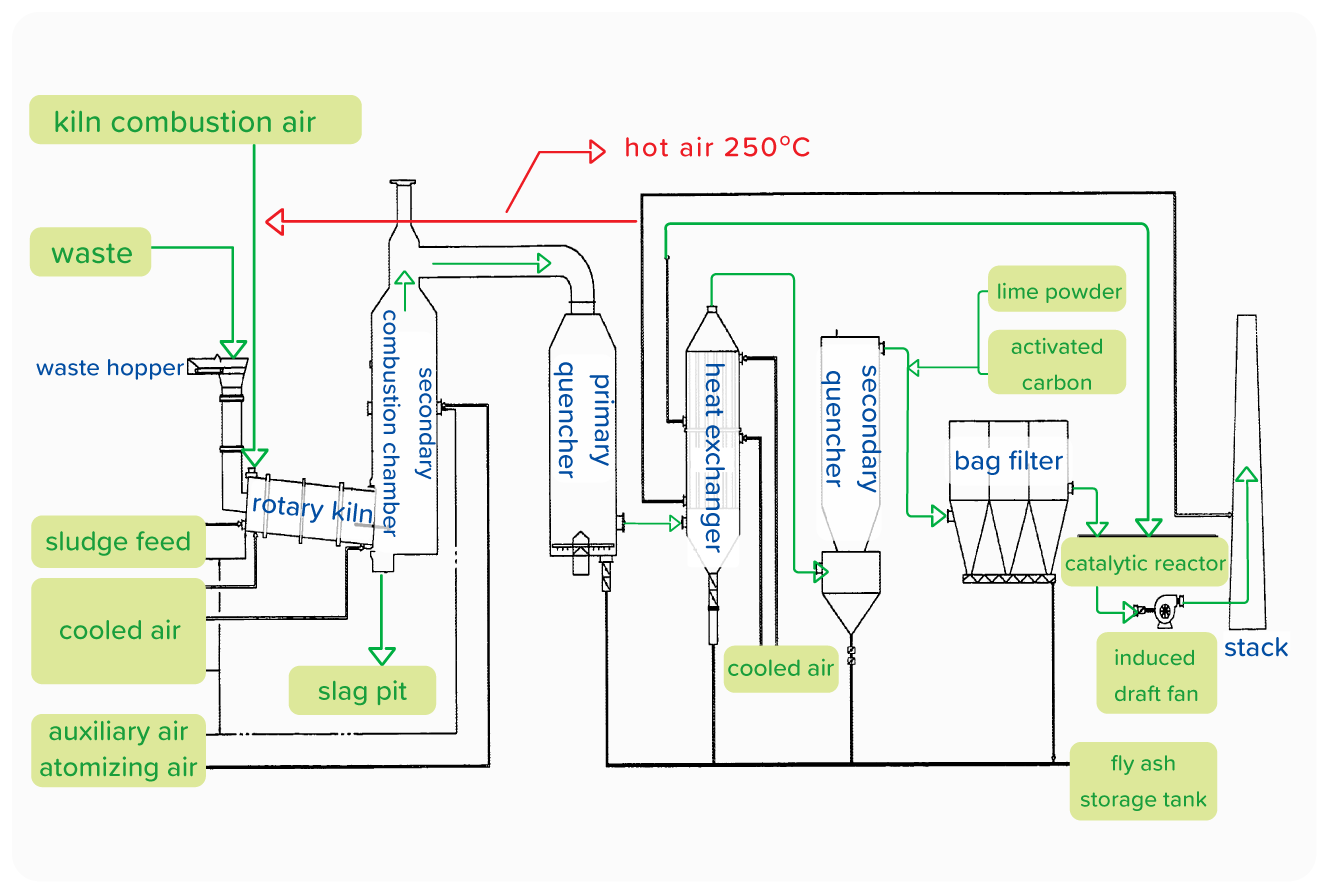

Having established a firm foothold in waste disposal management and EfW plants for over 20 years, ECOVE has been tasked with managing operations, carrying out annual repairs and revamps or improving system and equipment functions at more than two-thirds of the 24 energy-from-waste (EfW) plants in Taiwan. It is also the first company in Taiwan to export local EfW technology overseas. Equipped with professional experience in EfW, ECOVE offers technological solutions and O&M services. It also offers bespoke solutions involving equipment upgrade and efficiency enhancement for EfW plants that come with different incinerator types and designs. As a result, ECOVE helps local authorities and proprietors in addressing waste disposal issues. TIAIP has been in operation since 2004. It is equipped with rotary kiln-type incinerators that mainly process waste generated in Taoyuan International Airport Park. The sources of waste include airport terminals, aircrafts, TIAP administrative units, airline companies, kitchen waste from airline catering companies, sludge from the airport's wastewater treatment plant, and agricultural products or destroyed products that fail to comply with customs requirements.

Taoyuan International Airport Incineration Plant (TIAIP), an Energy-from-Waste plant

Due to the complexity and high moisture of waste content, as well as the nature of rotary kilns, TIAIP requires ongoing heat supply from combustion engines to ensure that the temperature of incineration chamber meets regulatory standards. As a result, problems such as low disposing capacity, high auxiliary fuel consumption, poor slag ignition quality, and high equipment failure rate have long plagued TIAIP since operation. Full combustion of waste relies on three factors: Temperature, time, and turbulent flow. Turbulent flow is kiln combustion air channeled into the rotary kiln to ensure full mixture of air and waste. The stronger the turbulent flow, the better the mixture of air and waste. This helps waste to be fully combusted, hence reducing reliance on auxiliary fuels. TIAIP’s rotary kiln has a poorer waste combustion efficiency because the amount of turbulent flow is inadequate to allow full mixture of kiln combustion air and waste. The inadequate amount of turbulent flow is the result of rotary kiln design: Combusted air comes from air drawn by primary air fans from storage pits and enters the rotary kiln through hole-like air gaps on the front wall and ring-shaped air gaps surrounding the front wall. Most of the air enters the rotary kiln through the surrounding ring-shaped air gaps, with air volume evenly dispersed around the incinerator body. Since air pressure is low, the amount of turbulent flow generated is inadequate. To cope with this problem, TIAIP needs additional heat supply from combustion engines to meet combustion quality. But since additional heat supply would require more fuel, which is against TIAIP’s goal of carbon reduction and energy conservation, TIAIP also needs an effective solution to raise combustion air pressure inside the rotary kiln, so as to increase turbulent flow. Therefore, ECOVE introduced a dual-method total solution that optimizes the combustion system at TIAIP:

- Recycle waste heat from heat exchangers and channeled the heat to the primary air fan system. At 250°C (see Fig. 1), kiln combustion air temperature is raised to speed up the waste drying process.

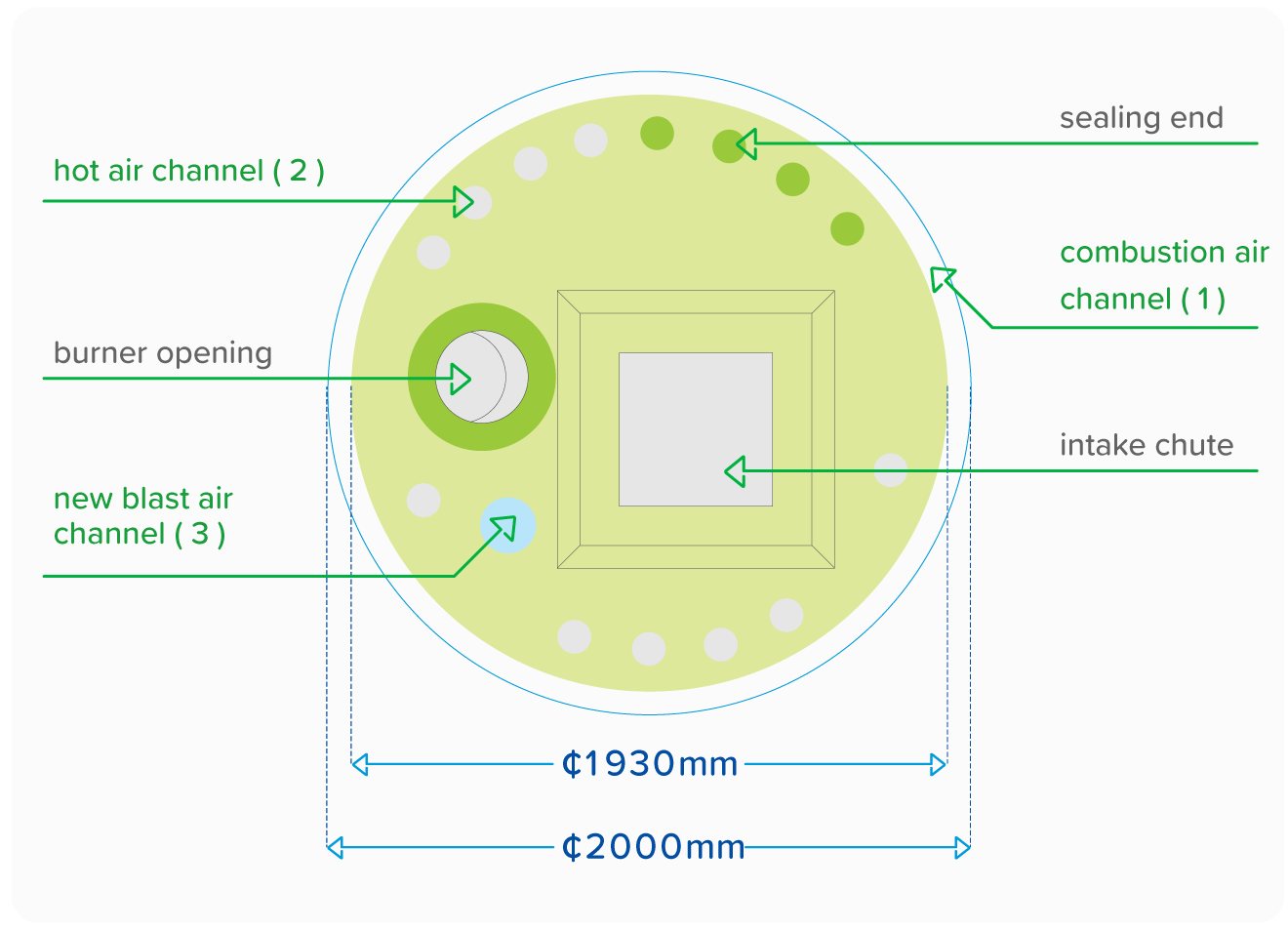

- Reconfigure kiln combustion air intake by using a three-air flow supply mode in place of the originally designed kiln combustion air supply method (see Fig. 2). The first air flow involves air from the ring-shaped air gaps surrounding the front wall. The second air flow involves air from small air gaps on the front wall, with a number of air gaps on the upper right corner being sealed so that the air volume becomes unevenly distributed. As air enters the incinerator, it will flow spirally clockwise along the incinerator wall. The first two air flows are provided by primary air fans. Idle blowers below the incinerator provide an additional, third air flow at pressure of between 500 and 600 mmH₂O, which is very strong combustion-supporting air (also known as blast air). The combustion-supporting air is now concentrated in the waste feeding area to increase the amount of air turbulent flow, thus effectively addressing insufficient air pressure problem and speeds up waste combustion.

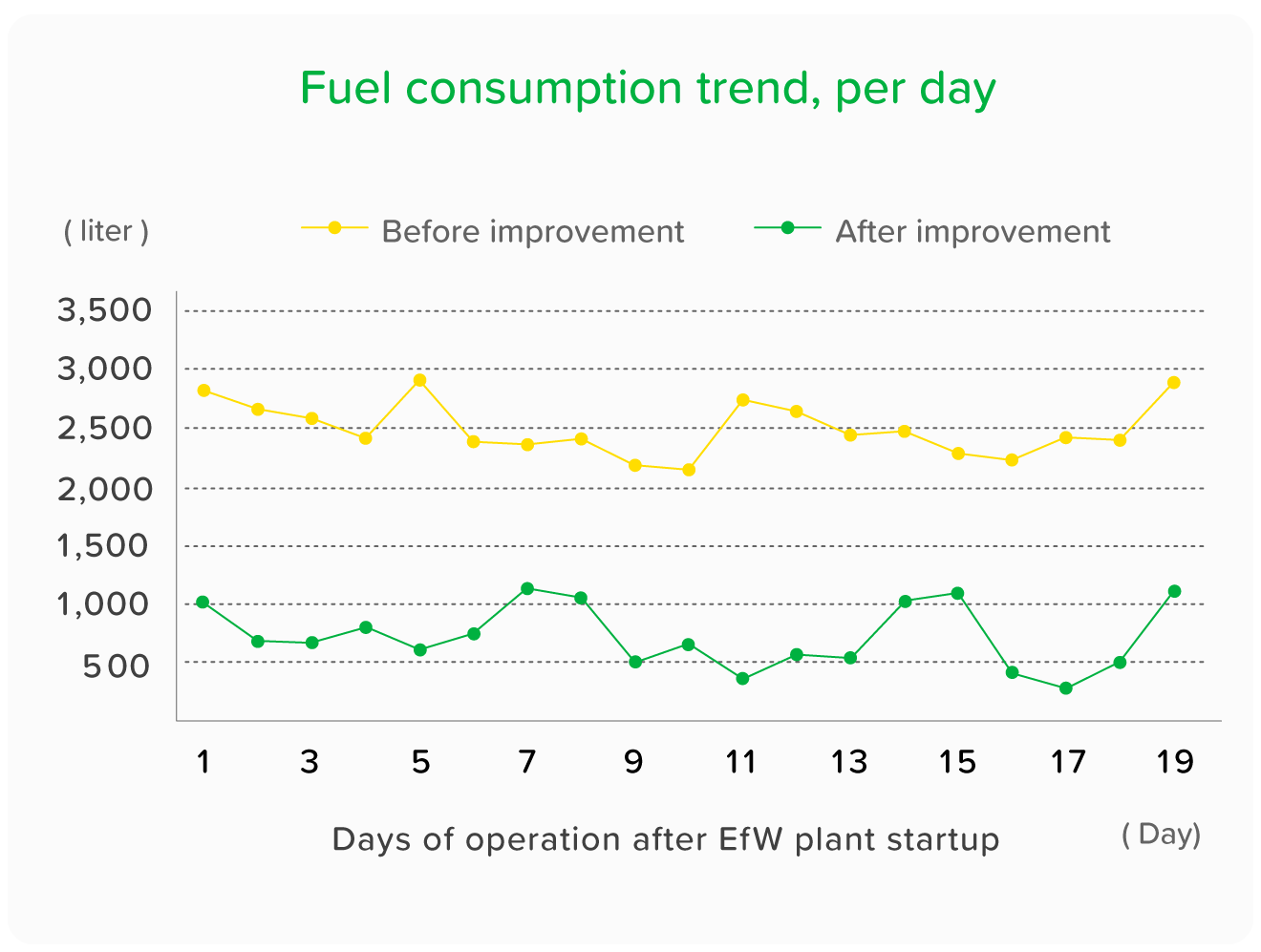

By employing these two methods, ECOVE has effectively increased the temperature and turbulent flow of combustion air inside the kiln. Combustion-supporting air inside the rotary kiln flows like a vortex, mixes with heat energy released from waste incineration process, and thus forces waste inside to dry and burn on its own. Coupled with reconfiguration of air preheating and distribution, TIAIP no longer needs to consume too much amount of auxiliary fuel (see Fig. 3).

Fig. 1 Waste heat is recycled to effectively speed up waste drying.

Fig. 2 To increase turbulent flow, some air gaps are sealed so that kiln combustion air is distributed unevenly.

Fig. 3 Diesel consumption drops drastically after improvement of combustion system.

Controlling waste composition variation to optimize combustion quality

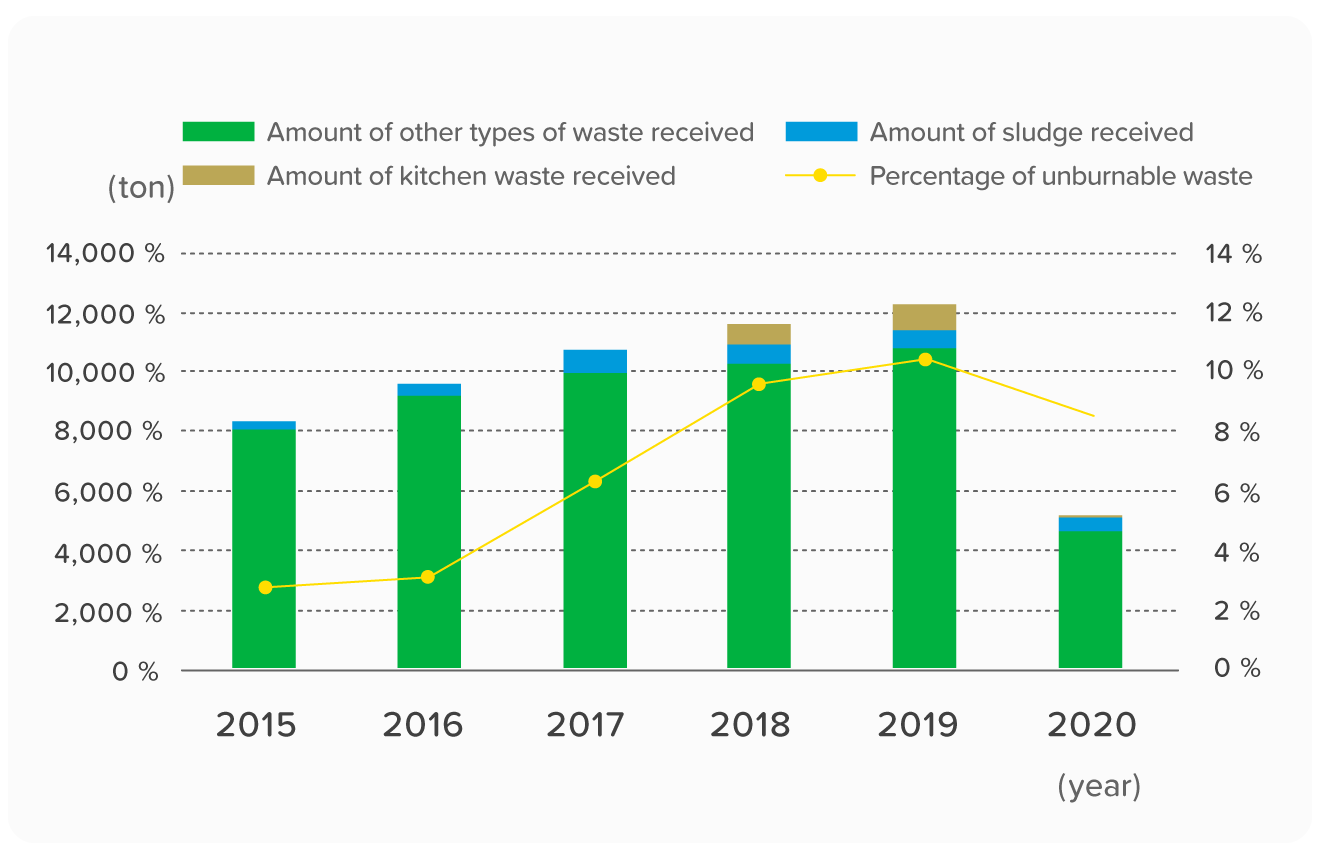

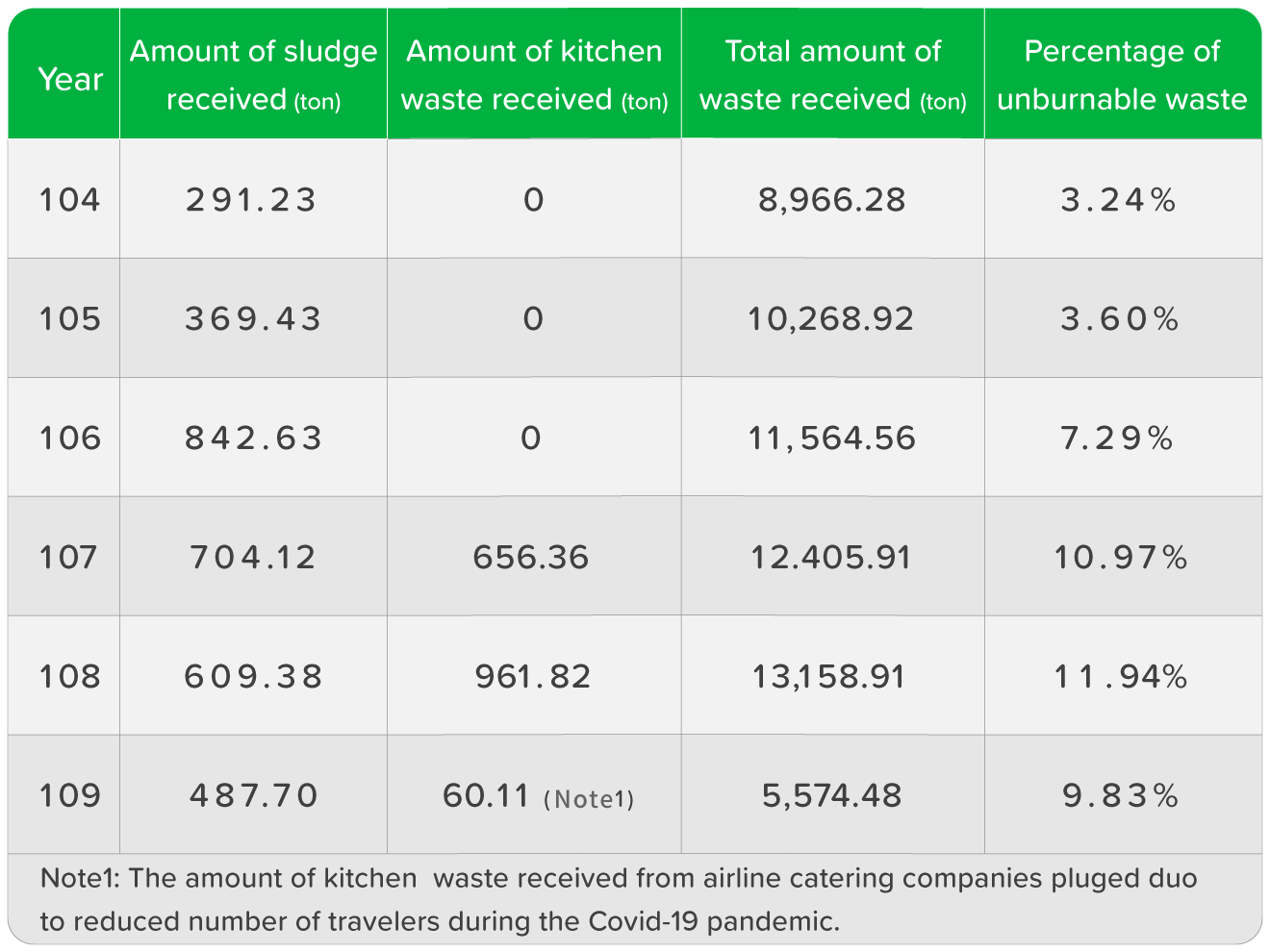

Among all waste inside the airport park, some waste are unsuitable for incineration, which includes wastewater treatment sludge, kitchen waste from airport restaurants and airline catering companies. As passenger volume at Taoyuan International Airport hit record high in recent years, there has been a rise in the amount of airport waste and unburnable waste (see Fig. 4 and Table 1). Unburnable waste contains high moisture content and has low calorific values, and is the main reason behind waste unbalance. Without proper management of storage pits and thorough waste mixing to ensure homogenization, it is easy to run out of enough storage pits, thus requiring more frequent startups and shutdowns. Without proper control over waste combustion, fuel consumption would increase. ECOVE addresses this problem by optimizing O&M practices to ensure more stable incineration quality. This includes monitoring startup and shutdown schedule, as well as reducing fluctuations of waste properties. Specifically, we did the following:

- Set up an appropriate waste collection schedule for TIAP. Avoid kitchen waste and sludge mixing with dry waste through separate collection. Wastewater from garbage trucks is also collected separately to reduce the amount of water entering storage pits.

- Crush waste in storage pits twice to increase surface area, which helps speeding up combustion process.

- Divide the storage pit into various zones for waste stacking: sludge zone, kitchen waste zone, waste storage zone, and waste mixing zone. This is a good way to ensure full utilization of storage pits.

- Fully mix dry waste with sludge and kitchen waste before incineration. The mixture is then fed into the incinerator in stable manner and with controlled quantity. This ensures stable calorific values for combustion.

Due to Covid-19 and the plunge of inbound and outbound passengers since 2020, there has been a massive change in the amount of waste generated, as well as waste properties. Compared to 2019, total amount of waste received by TIAIP is now down to 40%. The amount of kitchen waste from aircrafts and sludge dropped to about 1% and 3%, respectively. An increase in border quarantine medical waste, coupled with huge decrease in kitchen waste and sludge, have led to a continuous rise of waste calorific values. Moreover, due to insufficient amount of waste to be burned, incinerators are forced to shut down, and waste needs to be temporarily stored in storage pits, which makes waste stacking and storage even more important. ECOVE helps TIAIP improve incineration quality by adjusting operation parameters based on the variations of waste composition. Parameters include: waste mixture and distribution ratios, kiln combustion air distribution, startup and shutdown time for auxiliary combustion engines, and rotational speed of rotary kilns. These prove to be the key to optimization. Enhanced waste incineration efficiency means much better incineration quality, which reduces pollutants and carbon emissions.

Fig. 4 Variations in Taoyuan International Airport Park’s Waste Composition

Table 1 Details of Unburnable Waste

Keeping Covid-19 at bay, caring for community

For 11 years, ECOVE has kept improving waste treatment efficiency for TIAIP, bringing new life to an aging plant. Thanks to continuous optimization of combustion quality and equipment upgrade, TIAIP now consumes lower diesel in incineration and more than doubles the annual waste disposal capacity from 4,700 tons—when ECOVE first took over O&M for TIAIP— to 11,000 tons. This will be sufficient to meet the surging disposal demand for waste once Terminal 3 begins commercial operation. ECOVE plays an important role in protecting communities from Covid-19 by handling industrial waste generated from international flights, such as worn personal protective clothing. The company also works with airport authority and local Environmental Protection Agency to dispose local household waste where treatment capacity of TIAIP allows, fulfilling corporate social responsibility. Looking forward, ECOVE will strive to become “the most reliable provider of sustainable resource cycling services.”