Innovation

企業創新

Reducing Air Pollution and Protecting the Environment—Discussion on Stability Improvement of Semi-dry Acid Gas Removal System of EfW Plants

At ECOVE, we have been deeply engaged in the field of EfW plants and mechatronics system maintenance for more than 20 years, assisting local governments and business owners to solve the livelihood issues of waste treatment. Among the 24 large-scale municipal waste incineration plants in Taiwan, we have assisted more than two-thirds of these plants in operation and maintenance, overhaul and revamping, and system as well as equipment effectiveness upgrade. In recent years, with the rise of environmental protection awareness, there is an increase in demand for air quality monitoring. Here, we would like to take the semi-dry acid removal system as an example to share how ECOVE can solve the problems encountered by existing equipment and enhance the performance of waste gas treatment through professional waste gas treatment technology. We have obtained the patent of "device for enhancing the performance stability of semi-dry waste gas treatment system" for this technology, effectively reducing air pollution and achieving the goals of energy conservation, carbon reduction and environmental friendliness.

Common Problems Encountered by Semi-dry Acid Removal System

At present, there are 24 incineration plants in operation in Taiwan, and more than two-thirds of the waste gas treatment equipment adopt semi-dry acid removal system, which uses the atomizer wheel to atomize the cooling water and slaked lime slurry into droplets through distributor with high-speed rotation. These droplets were then sprayed into the waste gas, to reduce the temperature of the waste gas and will react with the acid gas to remove harmful gas. As the system has the advantages of high removal efficiency and economized operating cost, it has become the mainstream system when these incineration plants were built. Since only one set of atomizer wheel is installed per each boiler on the semi-dry system for these incinerators, when something goes wrong, load-shedding or even maintenance shutdown are often inevitable, which not only increases operating cost, but also puts pressure on waste treatment for counties/cities with insufficient waste treatment capacity. Common system problems may include:

- The pipeline is prone to clogging, resulting in insufficient dosage

The pipeline of slaked lime slurry is easily clogged. In serious cases, it will lead to insufficient flow of lime slurry, rise of waste gas temperature and difficult control of acid gas emission concentration. - The change of waste property deviates from the original design value

In recent years, the waste property has changed significantly due to the promotion of policies such as mandatory classification, resource recovery, mixed combustion of general industrial waste and general waste, waste screening for activation of landfills, etc. When the waste property changes significantly, it may occur that while the semi-dry system reaches the upper limit of slurry flow, it is unable to effectively control the acid gas emission concentration, resulting in operational difficulty for combustion control. - When the atomizer wheel undergoes regular maintenance and replacement, it is necessary to shut down to replace with reserve set

The atomizer wheel has no redundant unit, it is thus necessary to shut down and replace with the reserve set during maintenance, resulting in a short period of time when the acid gas cannot be controlled through dosing, putting pressure on emission control.

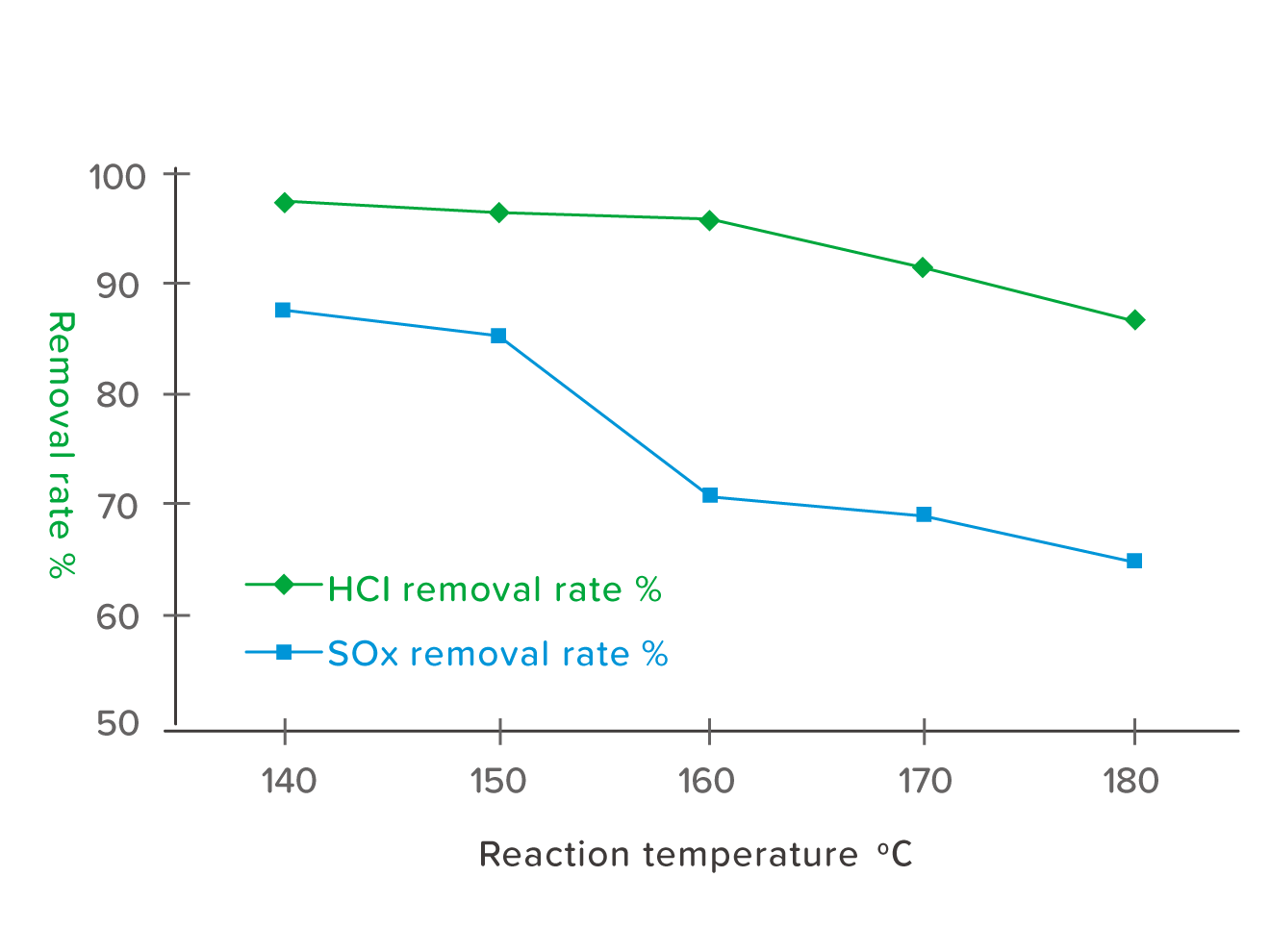

Figure 1 Effect of reaction temperature on acid gas removal rate of waste gas for semi-dry scrubbing tower.

Optimal Improvement Plan for Semi-dry Acid Removal System

In view of the above common bottlenecks in operation, we use root cause analysis to select the two most important system operating parameters, "reaction temperature" and "sufficient chemical dosing," to address problems encountered for the semi-dry scrubbing tower—the existing pollution control equipment. We then carry out system optimization design to improve the stability of the waste gas treatment system and reduce pollution emission. Detailed explanations are as follows:

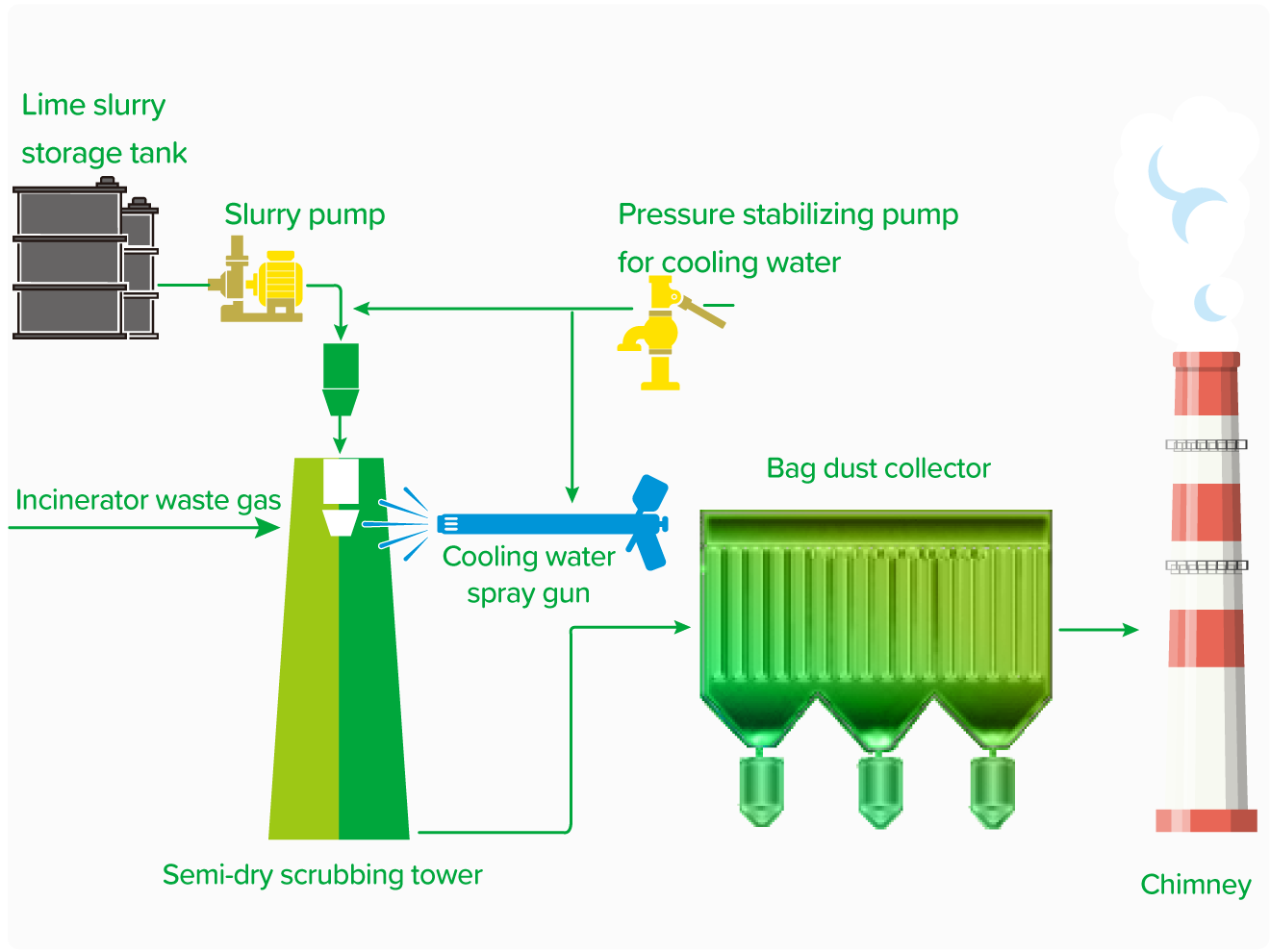

Figure 2 Addition of cooling water injection system.

- To ensure that the system maintains optimal reaction temperature

Figure 1 above shows the effect of semi-dry acid removal system on acid gas removal rate under different reaction temperatures. When the dosage is controlled at twice the theoretical value, lower reaction temperature will lead to better removal efficiency. When the reaction temperature of waste gas is controlled below 160℃, the acid gas removal rates for HCl and SOx can reach 95.7% and 70.6%, respectively.

Several situations may occur when the system operating temperature will rise to more than 160℃ , resulting in reduction of the acid removal system efficiency, including:1) the system cannot spray water for cooling purpose during the replacement of the atomizer wheel, or 2) the slurry pipeline is clogged and the system cannot provide sufficient slurry. If an auxiliary spray water cooling device can be added, this problem will be effectively solved. At ECOVE, we design and install a redundant cooling water supply unit on the top of the semi-dry scrubbing tower, as shown in Figure 2. When the reaction temperature of the waste gas rises, cooling water is atomized and sprayed into the scrubbing tower to mix with the waste gas for cooling purpose using double fluid atomizing spray gun, so as to keep the system in optimal reaction temperature or temperature range, improving the removal efficiency of acid gas, reducing the dosage required and achieving the benefits of energy conservation and carbon reduction. - To ensure sufficient dosage of slaked lime

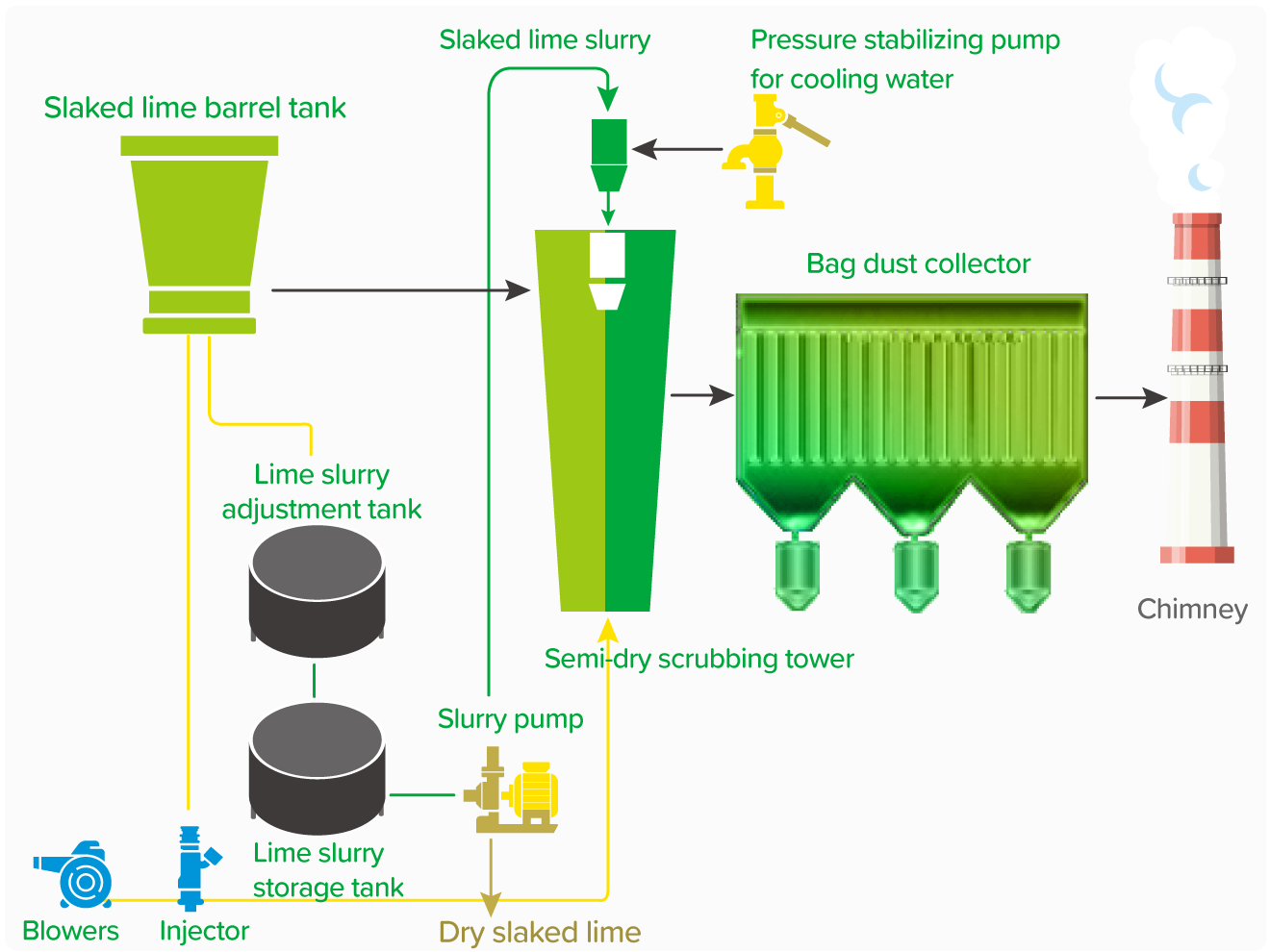

When the semi-dry system is not working or the waste property varies significantly, the acid gas will not be properly controlled to meet the management target value. In order to increase the dosage of chemical agents immediately and maintain the stability of acid gas pollutant emission, we design an auxiliary dosing unit in addition to the existing dosing system as shown in Figure 3. By adding a set of dry slaked lime injection system, we make sure the system will be initiated to increase the dosage of chemicals, improving the removal efficiency of acid gas and reducing the emission concentration of acid gas, in situation where an abnormal increase of acid gas emission concentration in waste is detected resulted from the sharp changes of waste property or broken facilities of semi-dry scrubbing tower.

Figure 3 Addition of dry slaked lime injection system.

Conclusion

With rich operating experience in EfW plants and continuous improvement of technology, we take the key factors affecting the acid gas removal rate obtained through this study as the best strategy to improve the stability of waste gas treatment system, effectively prevents and controls air pollution, which has also obtained the patent of "waste gas treatment system improvement—device for improving the performance stability of semi-dry waste gas treatment system" (see Figure 4). Looking forward to the future, we at ECOVE will continue to uphold the vision of being "the most reliable provider of industry-leading ‘resource cycling’ services " and do our part for environmental sustainability

Figure 4 Patent certificate of "device for improving the performance stability of semi-dry waste gas treatment system."