Outlook

趨勢展望

ECOVE’s Unceasing Effort to Reach Carbon Neutrality

Due to climate change, countries and companies all over the world are actively making carbon reduction commitments. ECOVE is no exception. In response to the trend of net zero emissions, ECOVE established ECOVE Solvent Recycling Corporation (ECOVE SRC) with recycling as its main business in 2018. The company assists semiconductor manufacturers to recycle and reuse the waste isopropanol generated during the production process; thereby reduces the carbon emissions that would have come from incineration treatment. Moreover, ECOVE SRC improves its plant-wide processes and uses green electricity. Not only have these practices helped the company achieve carbon neutrality for the whole plant, but have also helped it become the first company in Taiwan to obtain double certificates in circular economy and carbon neutrality, as the company moves towards the net zero goal by 2050.

Champion of carbon reduction and provider of one-stop services

Adhering to the concept of circular economy, green production and environmental friendliness, ECOVE selects high energy efficiency equipment for ECOVE SRC plant, introduces intelligent management system, and improves resource cycle performance (Figure 1). In contrast to the conventional way of waste isopropanol treatment by incineration, ECOVE adopts a separation and purification process to distill and concentrate waste isopropanol, so that it can be reused and sold as industrial-grade isopropanol. Compared with the incineration treatment method, this purification method can cut about 484 metric tons in carbon emissions and save energy, helping achieve green production and creating a green future. ECOVE is also actively conducting research with the academia to improve the technologies of waste isopropanol recycling.

Figure 1. A view of ECOVE SRC's process area (left) and plant exterior (right)

ECOVE established a strict control mechanism with regard to the quality and import of waste isopropanol. Waste isopropanol from different sources are inspected by ECOVE and third-party testing agency. Cleaning and transport is carried out by ECOVE Waste Management Corporation, a subsidiary of ECOVE (Figure 2). There is a sound product sales channel and a tracking and inspection mechanism in place to allow ECOVE to know where its products end up, and what purpose they are used for. All products undergo rigorous testing before they leave the plant, and are made sure that they comply with client requirements. In short, the company offers one-stop full services that encompass production, cleaning, transport, reuse, and disposal.

Low-carbon services through integrative technologies

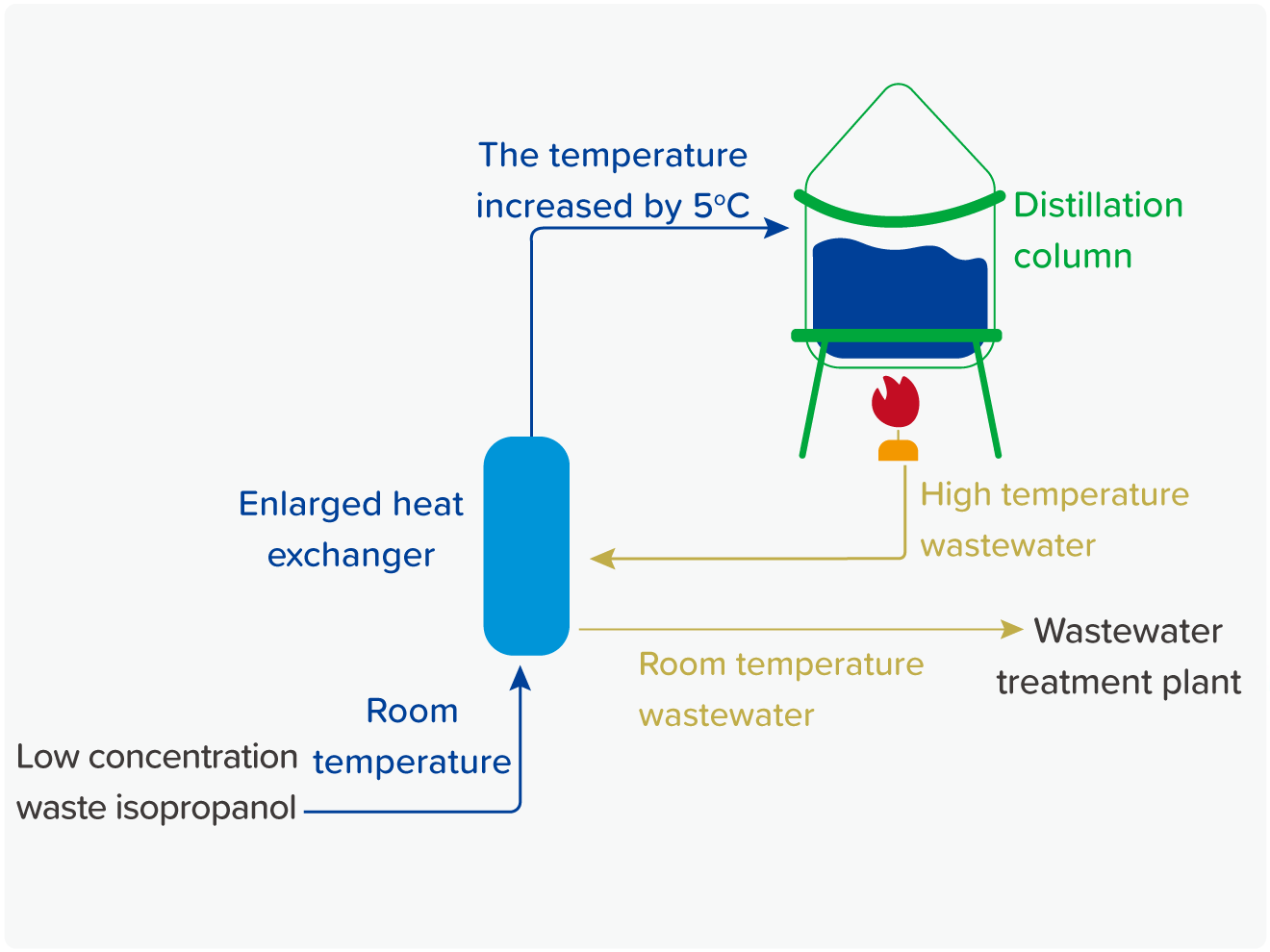

Based on the principle "Every Resource Counts," ECOVE adopts integrative technologies to help optimize resource usage efficiency and cut carbon emissions. Heavy oil, which is currently used as fuel for production, has been replaced by liquefied natural gas, a measure that helps cut emissions. The regulating tank’s transfer pump at the wastewater treatment plant is equipped with a frequency converter to reduce power consumption. The heat exchanger used to preheat raw materials (Figure 3) has been enlarged to improve raw material efficiency, lower fuel costs, and reduce carbon emissions. These are just some examples showing the actions ECOVE SRC has taken towards reaching the goal of "low-carbon and sustainable management."

Figure 3. The heat exchanger is enlarged to increase the temperature of preheated raw materials

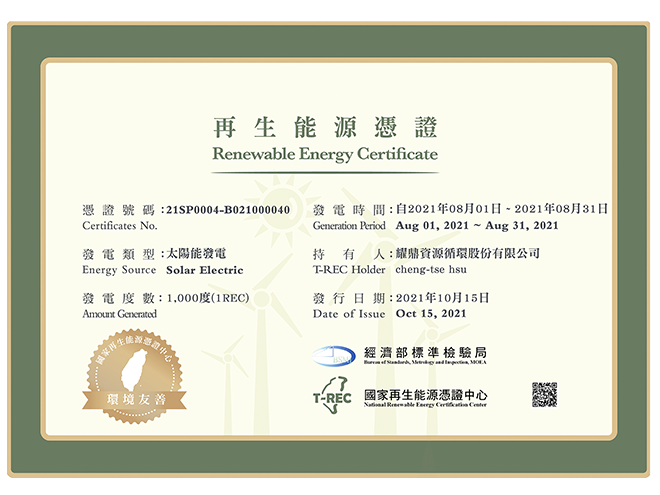

In addition to the above efforts, ECOVE took the lead in consuming renewable energy, as a way of mitigating climate change impact. Beginning in May 2021, green electricity is bought and used for plant operations (Figure 4), and currently accounts for 20% of plant-wide power consumption. This helps cut carbon emissions by about 5.2 metric tons per month. Moreover, ECOVE regularly conducts greenhouse gas inventories, calculating how much emissions the company has emitted. By comparing the historical inventory results, the company can then identify emissions hot-spots and more opportunities for carbon reduction.

Figure 4. ECOVE SRC’s renewable energy certificate

An outstanding company in resource cycling with double certificates in circular economy and carbon neutrality

Another aspect of ECOVE SRC’s carbon emission reduction efforts is its plant design. Its plant features energy-efficient equipment, as well as smart and systematic management. These measures played key role in helping ECOVE SRC reach the milestone of plant-wide carbon neutrality, which was verified by BSI based on the internationally accepted PAS 2060 specification. ECOVE SRC has thus become the first company in Taiwan to obtain double certificates of circular economy and carbon neutrality. Moreover, ECOVE SRC won the most prestigious 2-Star Award in the selection of "Outstanding Circular Economy Enterprise" by the Environmental Protection Administration, Executive Yuan in 2021 (Figure 5), for the contribution of circular economy and green production ECOVE SRC made in terms of waste isopropanol recycling and reuse. Thanks to ECOVE SRC’s integrative technologies, waste isopropanol is given a second life in the market, helping the company, the clients, and the Earth alike. Circular economy and zero emissions are not only what we envision, but also what we have been doing to fulfill that dream.

Figure 5. ECOVE is the recipient of "Outstanding Circular Economy Enterprise 2-Star Award". On behalf of the company, Yun-Peng Shih (right), President of ECOVE, receives the award from Hung-Teh Tsai, Deputy Minister of the Environmental Protection Administration.