Outlook

趨勢展望

Trends in the Market of Waste Solvent Treatment and Recycling

To achieve the goal of net zero emissions, circular economy has become a global trend. In Taiwan, the government has announced the 2050 Net-Zero Emissions Roadmap, in which Resource Recycling and Zero Waste is one of the 12 key strategies to guide the green transformation of industries. Meanwhile, the European Union (EU) released the Carbon Border Adjustment Mechanism (CBAM), the world's first carbon border tax program, in May, 2023, which will be put into trial implementation on October 1, 2023 and officially take effect on January 1, 2026. This signifies that climate regulation has officially been incorporated into global trade rules. Therefore, circular economy is not only the key to achieving net zero, but is also an influence on the future development of businesses. In response to the need for treating enormous amount of waste solvent produced by the booming high-tech industry, ECOVE Environment Corp. (ECOVE) established ECOVE Solvent Recycling Corp. (ECOVE SRC) by leveraging its years of experience in the field of waste management. ECOVE SRC aims to assist the high-tech industry in handling waste, with waste solvents as one of its main business operations. Through active, innovative research and development in the area of waste solvent, ECOVE has obtained multiple patents and assisted numerous domestic high-tech clients in handling process-generated waste liquid and bringing it back to the market supply chain. Additionally, ECOVE can help set up on-site waste solvent treatment facilities according to client needs and circumstantial conditions. With comprehensive customized solutions and diverse services, ECOVE collaborates with clients to reduce waste, decrease capacity, and minimize carbon emissions, effectively implementing a circular economy.

Semiconductor Industry Development Driving the Advancement of Waste Solvent Treatment Technology

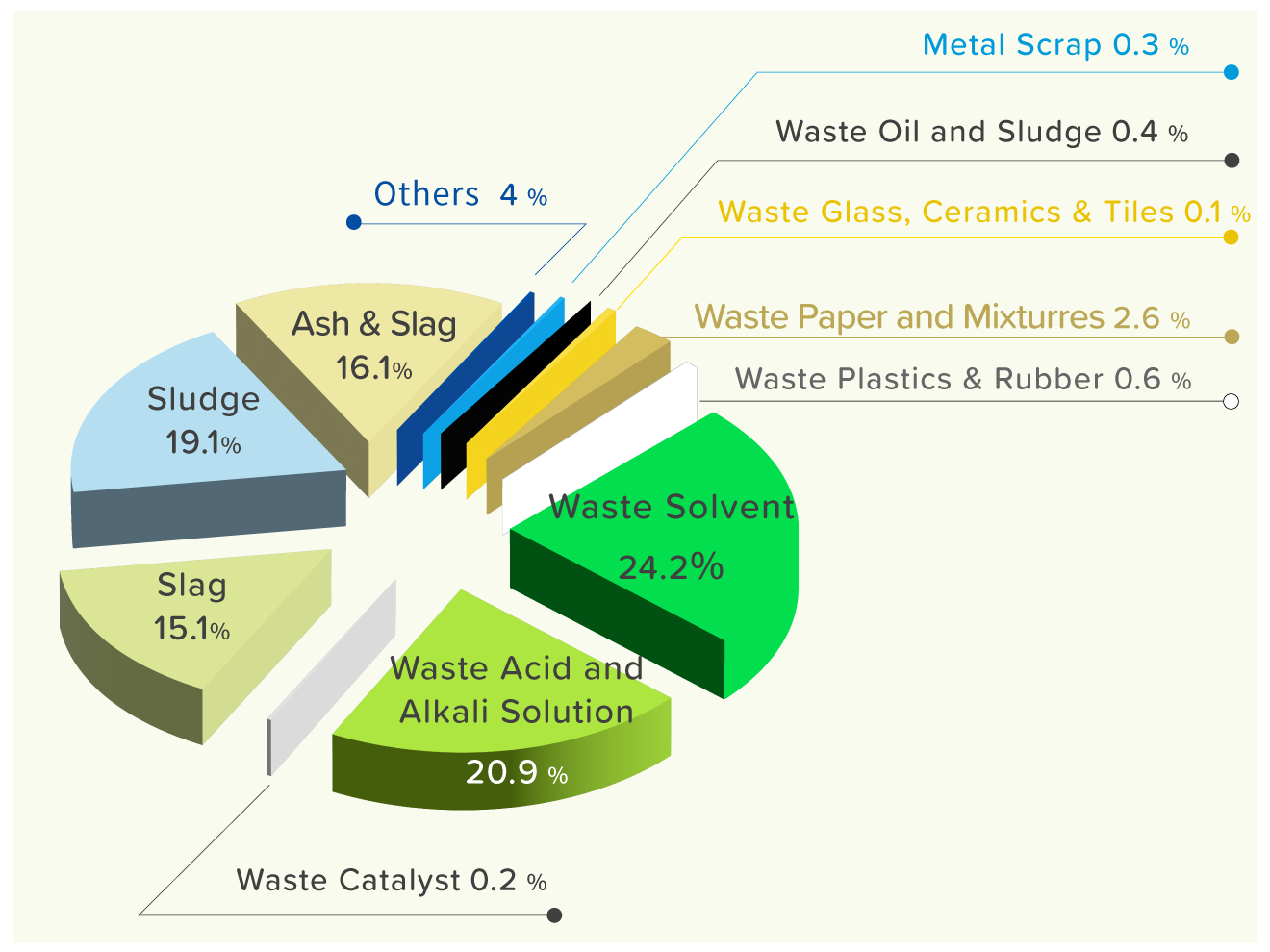

Today, new and innovative technologies such as the Internet of Things, electric vehicles, mobile communication, and high-performance computing are all in need of more optimized chips. This has driven the development of the semiconductor industry and led to the advancement in nanometer scale and adjustments in production processes, resulting in changes to the composition and the volume of waste solvent generated. According to the classification of industrial waste recycling channels by Taiwan’s Industrial Bureau of the Ministry of Economic Affairs, there have been a total of 142 licensed reutilization plants assisting companies in handling industrial waste as of 2022. Based on the actual reutilization declaration data, the estimated reutilization proportion of different industrial waste is charted as below. "Waste solvent" is the most frequently reutilized industrial waste, with a proportion of 24.2%. Among all categories of waste solvent, the largest quantity of reutilization is "waste liquid with a flash point below 60℃ (excluding alcoholic waste with an ethanol volume concentration below 24%)," among which waste isopropanol produced by the integrated circuit manufacturing industry accounts for the majority, and is mainly reutilized as an industrial-grade solvent.

The reutilization of different industrial waste permitted for reutilization in 2022 (source: The 2022 Program of Promotion and Review Management of the Resource Recycling Industry: Current Development - The Information Network of Industrial Waste Disposal and Resourcezation)

To support the circular economy, many high-tech companies not only outsource waste solvent treatment to licensed recycling plants, but also continue to seek new green technologies and invest in the construction of their own reutilization system for waste reduction and minimization. In doing so, the recycling technology is incorporated into their facilities to achieve closed circulation as well as optimize carbon reduction benefits. ECOVE has a good understanding of waste properties and the market, as well as the ability to assess and integrate technical expertise. With its considerable experience in waste solvent recycling, ECOVE offers services in waste solvent treatment and set-up of waste treatment facilities, providing optimal solutions based on business needs and conditions. This is a comprehensive one-stop service that encompasses the generation, collection, disposal, reutilization of waste solvent and its return to the market supply chain.

Connecting and Integrating the Waste Solvent Recycling and Reutilization Techniques

The varying degree of complexity in the composition of waste solvent results in its various treatments. Common disposal methods include incineration, thermal treatment, and recycling. Mixed waste solvent with complex composition is incinerated or thermally treated to become fuel and auxiliary fuel for boilers. On the other hand, waste solvent with relatively simple composition is distilled for purification so that water and impurities are removed before its return to the high-tech industry processes or industrial cycles. For example, distillation is the most common technique for recycling and reusing waste isopropyl alcohol (WIPA). In this process, water is removed from the WIPA to reduce volume. Next, by using the azeotropic distillation technology, the regenerated IPA can be made into high-quality products according to different market demands. Having secured the permission for reuse on a general case basis from the National Science and Technology Council and the Ministry of Economic Affairs, ECOVE Environment Corporation has reached full capacity utilization rate, with annual recovery of approximately 15,000 tons, producing about 3,500 tons of industrial-grade IPA through reutilization. ECOVE Environment Corporation continues to conduct research and development of recycling and reuse of electronic-grade IPA, and has obtained a patent for the invention of the Isopropanol Regeneration System and Method this year. This method can allow one to concentrate the product to a purity level of 99.9% or even higher through valorization, and will be introduced into the high-tech industry in the future. In recent years, ECOVE Environment Corporation collaborated with several high-tech factories, assisting them in establishing on-site waste solvent treatment facilities to reduce carbon emissions generated from the reutilization process and achieve optimal reutilization efficiency. Although it is a trend for high-tech factories to build on-site waste recycling systems, the available space for new facilities in these already-built factories is nevertheless limited. Additionally, issues such as workflow, storage, and fire regulations are also necessary considerations for the establishment of waste recycling systems. Since the circumstantial conditions of factories might not meet these requirements, ECOVE provides customized solutions according to the particular needs of each company. Take a high-tech factory with limited space as an example. Its distillation system that ECOVE helped set up has the advantages such as a smaller footprint and higher processing efficiency. It also allows for the production of high-concentration waste solvent from low-concentration waste solvent through the on-site purification system, thereby reducing the amount of waste generated by approximately 88%. Then the high-concentration waste solvent is sent to ECOVE for further rectification and purification, thus reducing carbon emissions from transportation and valorizing the products for return to the market. In another example, ECOVE leveraged its patents and achievements in the reutilization field to connect and integrate different systems, thereby helping a company set up its on-site waste treatment facilities according to the different properties of various waste types, so that the waste can be regenerated into products and energy, achieving the dual benefits of “turning waste into resources” and “turning waste into energy.” In this way, ECOVE Environment Corporation implements circular economy jointly with its client companies.

ECOVE Environment Corporation offers corporate waste disposal services.

The pervaporation system

Conclusion

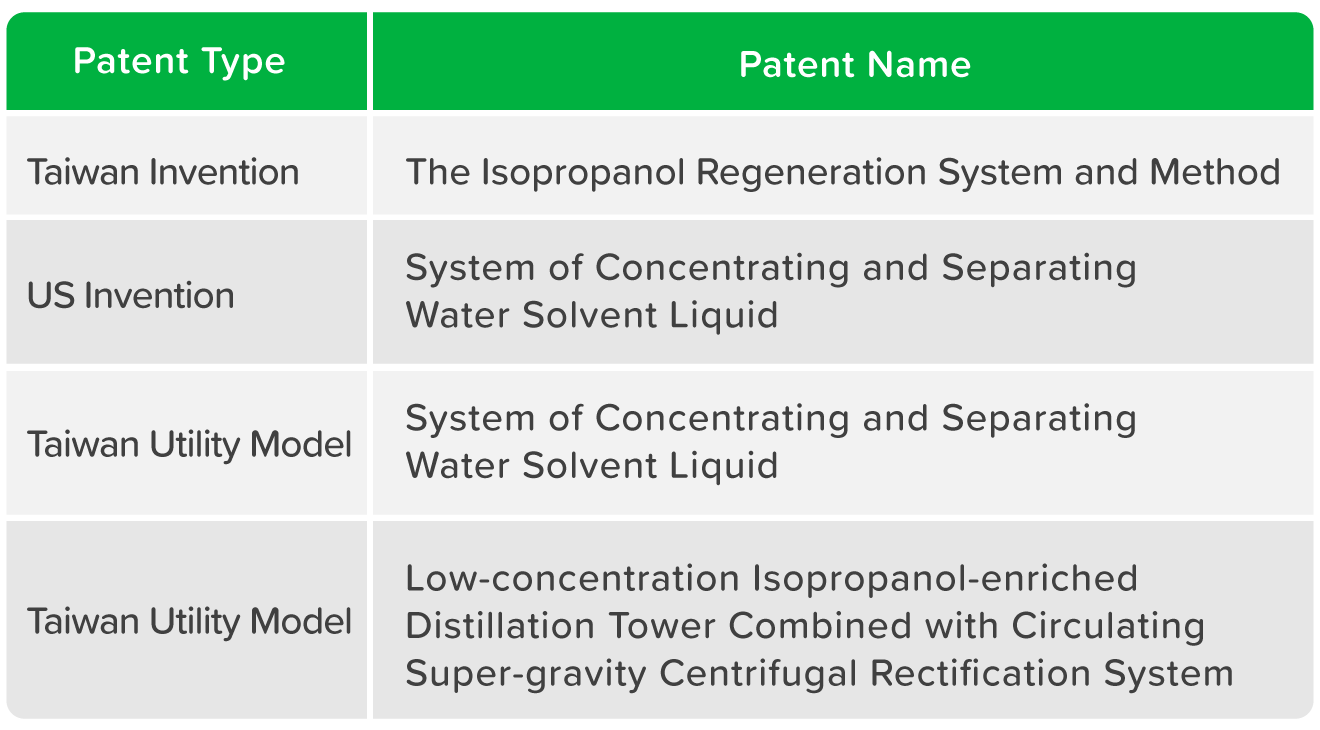

2050 Net Zero Emissions is a target for business sustainable development. ECOVE adheres to the concept of Every Resource Counts, continuing to improve technical integration and invest in the research and development of innovative and cutting-edge technologies. The company customizes the production process designs based on the waste properties and business needs, and has obtained several utility model patents and invention patents as shown in the table below. Fulfilling the spirit of "extending life cycle, re-manufacture and reuse," ECOVE is acting in accordance with its principle of Every Resource Counts. At ECOVE, we strive to provide companies with services that promote resource cycling efficiency and carbon reduction benefits through various improvements, creating a new service model for circular economy through corporate cooperation. In doing so, we put low-carbon sustainable operations into practice step by step, and also aspire to become the most reliable provider of industry-leading resource cycling services.

An overview of ECOVE Environment Corporation's patents in the waste solvent field