In terms of occupational safety and employee health management, ECOVE has fully implemented ISO 45001 to strengthen the construction of the occupational health and safety management system, effectively preventing occupational hazards and ensuring the safety and health of employees. We emphasize creating a safe workplace through risk identification and control, employee participation, and continuous improvement, highlighting a preventive approach and timely handling of potential occupational health risks to ensure that all employees can not only avoid accidents during work but also promptly identify and address potential hazards. At the same time, ECOVE provides a series of health and safety assurance measures, including mandatory occupational safety training, emergency response drills, and regular physical and mental health check-ups. We also place special emphasis on employee participation mechanisms by establishing a representative system for employees and holding regular communication meetings to ensure that every employee can take initiative in their work and participate in discussions and improvements regarding occupational health and safety issues. For our partners, ECOVE similarly requires collaborators to adhere to high standards of safety and health management regulations and actively engage in safety cooperation and technical exchanges. ECOVE regularly conducts safety management reviews and assessments of partners to ensure that all members of the supply chain comply with the requirements of ISO 45001, jointly ensuring the safety of the work environment and reducing the risk of workplace injuries and accidents.

ISO 45001 Certified

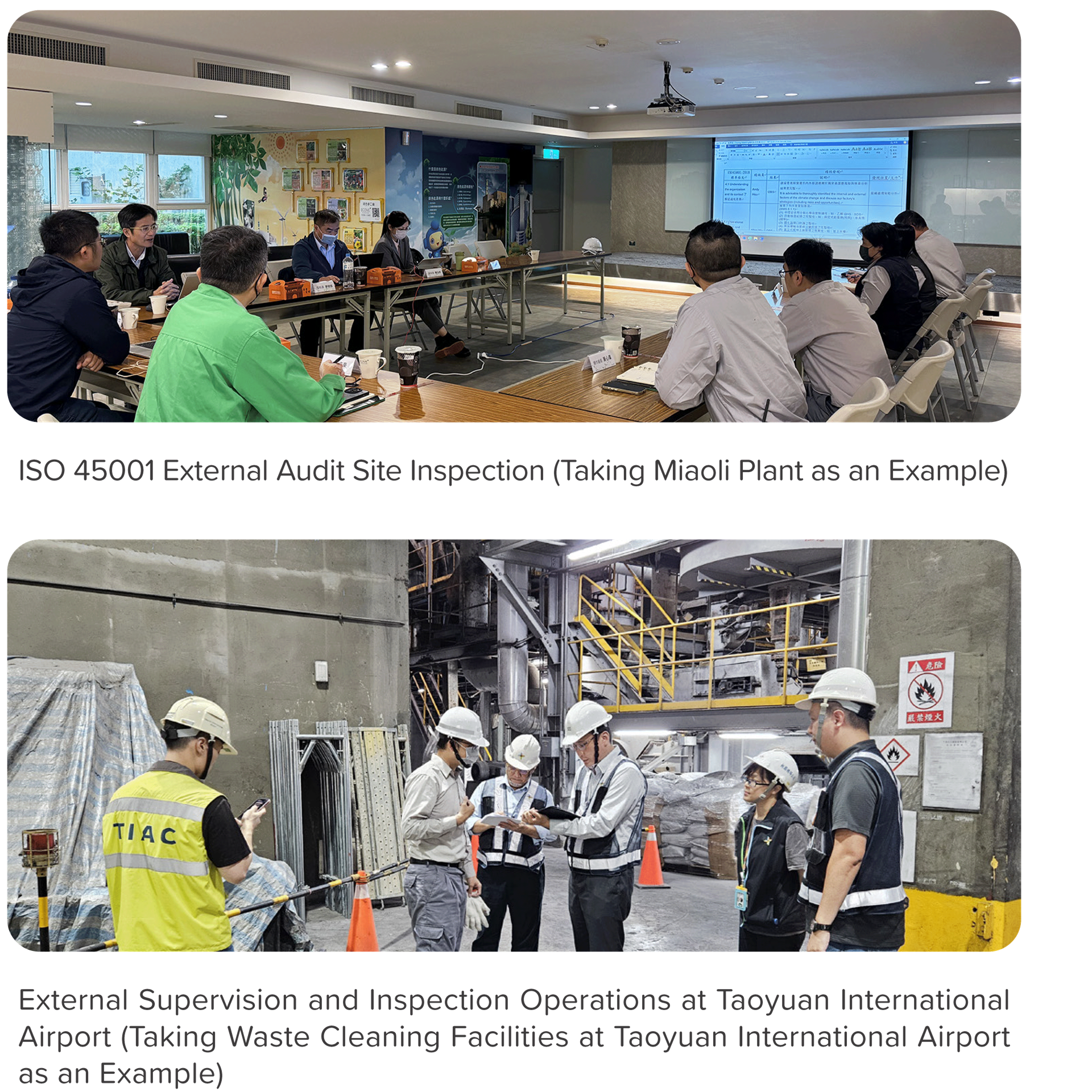

ECOVE has always adhered to the core spirit of prioritizing safety, health, and the environment, following seven major occupational safety and health policies to ensure that all operational sites meet the highest safety standards. Since 2009, ECOVE's ECOVE ESC and ten incineration plants have obtained OHSAS 18001 and TOSHMS certifications, and in 2011, in response to the Ministry of Labor's policies, they upgraded to CNS 15506, continuously passing verification. Since 2018, ECOVE ESC's ten operational sites, ECOVE WMC, ECOVE SRC, and SINOGAL have gradually obtained ISO and CNS 45001 certifications, ensuring that the occupational safety and health management systems, internal audits, and verification coverage at each operational site reach 100%, applicable to all employees, contractors, and subcontractors. In 2024, ECOVE ESC, ECOVE WMC, and ECOVE SRC once again passed ISO and CNS 45001 certifications, ensuring the continuous and effective operation of the occupational safety and health system.

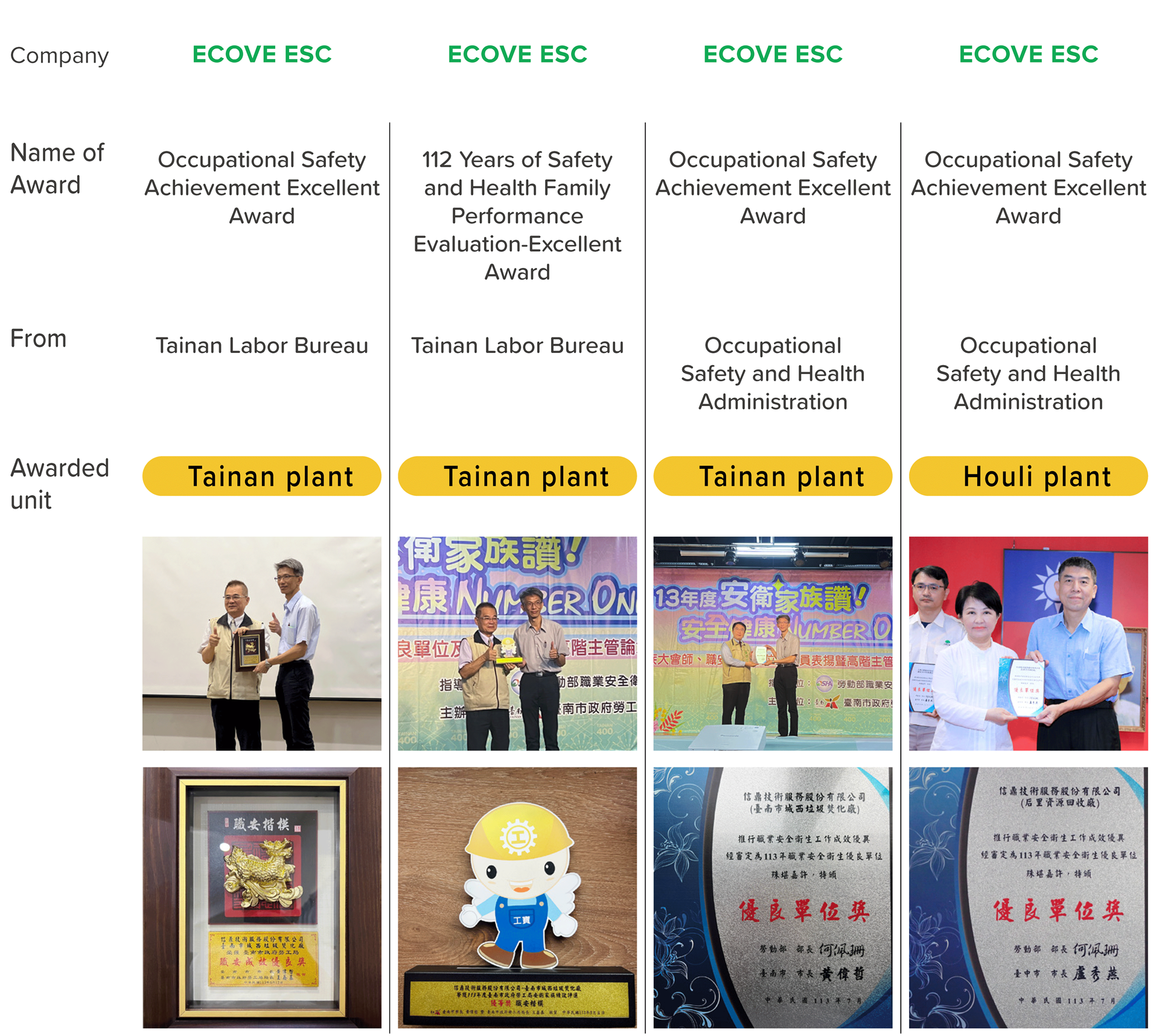

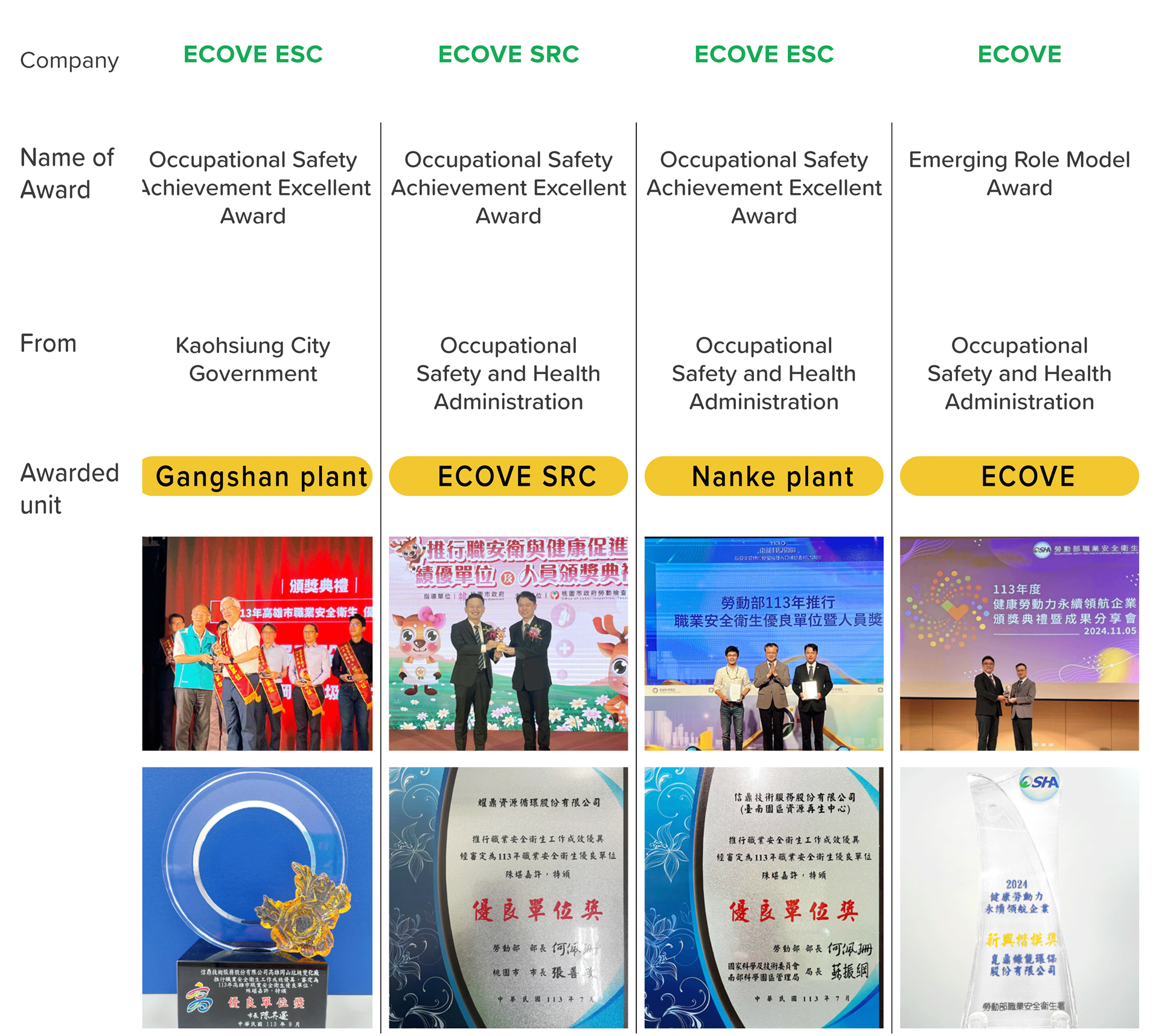

Award Achievements

To actively promote the development of a safety and health culture and strengthen self-management in safety and health, ECOVE encourages various units to participate in external safety and health evaluations, consistently achieving excellent results,showcasing our effectiveness in promoting safety and health. In 2024, ECOVE and its subsidiaries received the following awards:

Policies and Committees

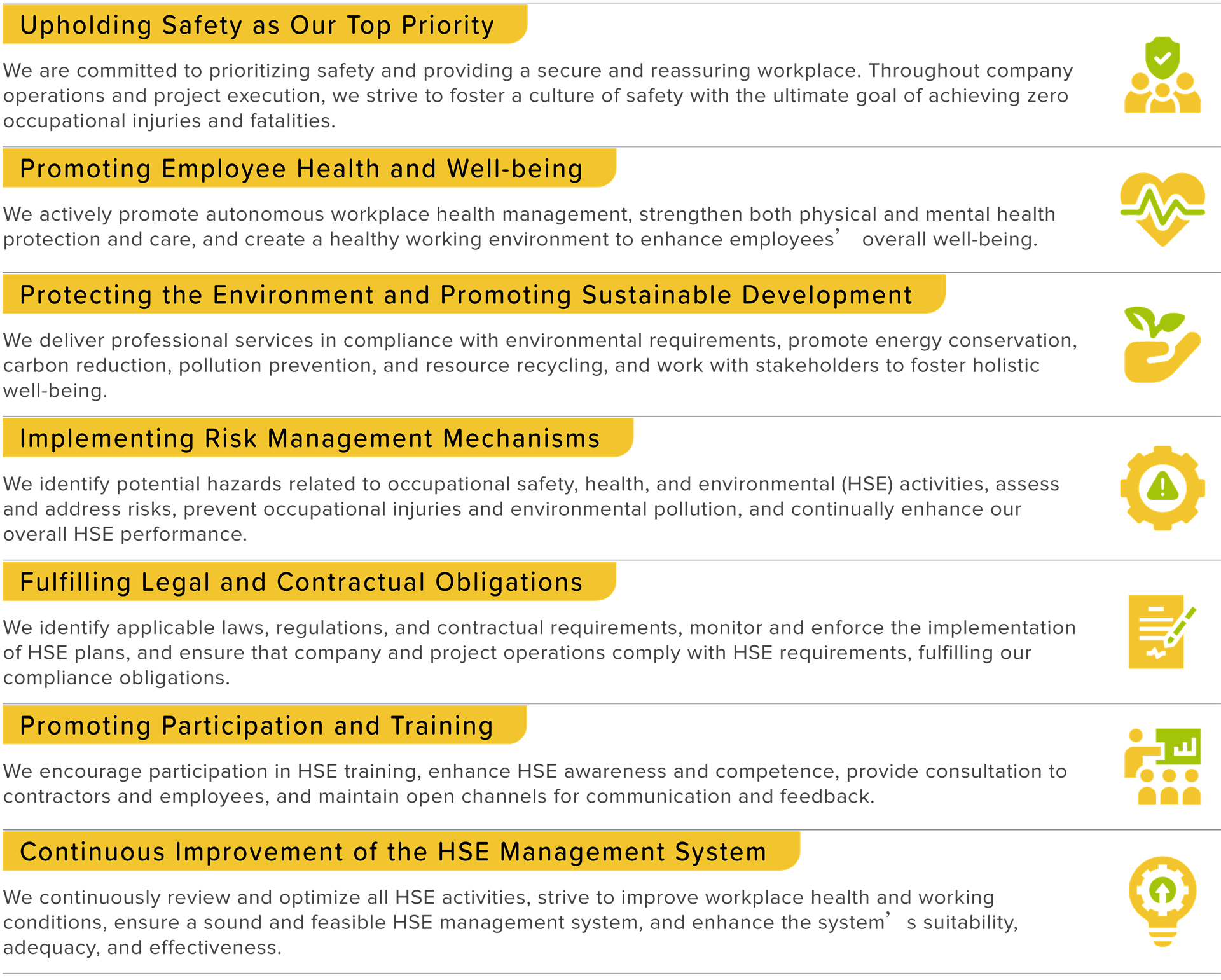

ECOVE's health, safety, and environmental policy is always centered on fulfilling environmental protection and creating a safe and healthy working environment. Furthermore, it integrates the spirit of the ISO 45001 Occupational Health and Safety Management System, committed to creating a worry-free working environment for employees and partners, ensuring their physical and mental health and well being.

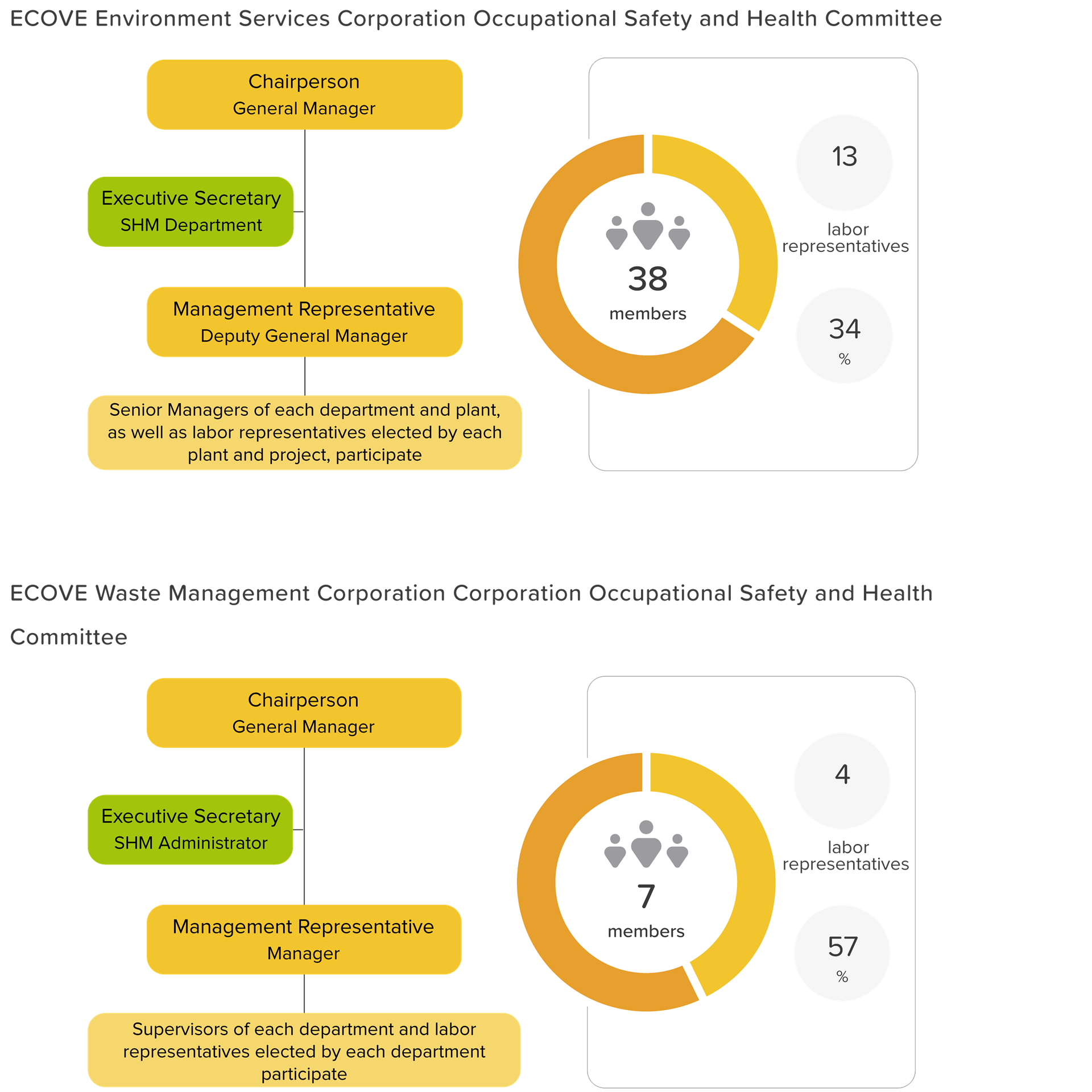

The Occupational Safety and Health Committee is an important organization within the ECOVE safety management system, responsible for coordinating and guiding all employees in matters of occupational health and safety. This committee is composed of both management and employee representatives, tasked with monitoring workplace safety conditions, promoting safety culture, investigating and handling incidents, and regularly reporting safety management progress to management. It ensures that the safety training needs of employees are met, as well as the continuous improvement and effectiveness of safety management policies and measures. In ECOVE and its subsidiaries, ECOVE ESC and ECOVE WMC have reached the legal scale and established committees, while ECOVE, ECOVE WEC, ECOVE MEC, and ECOVE SRC have not met the establishment standards and therefore do not have committees. However, the spirit of the system is still followed on-site, allowing employees to regularly participate in weekly or monthly meetings with supervisors to communicate on occupational safety and health issues on the agenda. The Occupational Safety and Health Committees of ECOVE ESC and ECOVE WMC meet quarterly, and the results of these meetings are communicated to employees and non-employees through the website or bulletin boards to convey the spirit and content of the safety committee.

Risk Assessment and Operational Safety Control

ECOVE and its subsidiaries adopt a tiered management strategy, integrating a risk management committee to systematically identify, assess, and control occupational safety and health risks. The core of safety and environmental risk management involves conducting at least two comprehensive risk assessments annually, covering operational processes, chemical management, hand tool usage, and environmental exposure. Risks are categorized based on their severity, and corresponding standards are established to ensure employee safety. To enhance risk awareness, the company regularly holds promotional activities to ensure that all regulations are implemented in daily operations. In terms of occupational safety and health discussions, ECOVE provides employees with an email system, proposal improvement, and reporting mechanisms through the EIP (Enterprise Information Platform) to achieve rapid hazard reporting and allow for anonymous feedback, thereby protecting employee rights and strengthening the organization's ability to respond to potential risks in real-time. Additionally, ECOVE conducts regular on-site audits to review the applicability of operational standards and makes adjustments based on on-site feedback to ensure continuous optimization of standards. Through dynamic adjustments to operational regulations, the company not only enhances the efficiency of operational processes but also further strengthens overall workplace safety, ensuring employee health and workplace safety. We have established a series of operational safety control regulations for high-risk and hazardous jobs, such as rotating equipment maintenance, pipeline maintenance, hot work operations, confined space operations, elevated work, hoisting operations, and electrical work, to ensure that each high-risk operation is conducted in a controllable environment, striving to achieve the goal of "zero accidents." ECOVE utilizes the self-developed MMIS (Maintenance Management Information System) for daily work task allocation, and during morning meetings, potential hazards are identified and safety regulations are promoted through Job Safety Analysis (JSA) to ensure that employees understand the operational risks. Before operations commence, operators, maintenance personnel, and safety personnel must jointly inspect the on-site safety conditions according to risk control regulations, including de-energizing, isolating, and implementing lockout/tagout procedures, confirming that there are no hazards before starting work to ensure safety throughout the process.

Occupational Health and Safety Environmental Risk Assessment Process

- STEP 01:Occupational safety and health hazard identification

- STEP 02:Risk Assessment

- STEP 03:Determine control measures based on risk assessment

- STEP 04:Safety and health objectives/operational controls/emergency response/training/monitoring

Occupational Safety Control

- STEP 01:Establish safety control regulations for hazardous and harmful work

- STEP 02:MMIS job assignment

- STEP 03:Job Safety Analysis (JSA) hazard communication

- STEP 04:Work permit application

- STEP 05:Work can only proceed after joint confirmation by all three parties

Strengthening Security Management and Auditing

To strengthen safety management, ECOVE ESC continuously improves through an auditing system and implements safety management and improvements in a gradual manner. Through audit verification, the safety knowledge and skills of employees are confirmed, areas needing enhancement are identified, and these are incorporated into training programs and the basis for revising operational standards to ensure the continuous optimization of safety management. ECOVE ESC promotes a three-tier auditing management system to ensure the implementation of safety management. The audit results are reported in committee meetings, detailing the number of sessions and deficiencies, while the improvement aspects are managed by the responsible departments for each incineration plant and project. Additionally, the effectiveness of improvements is confirmed through a re-audit mechanism to ensure the continuous advancement of safety management.

The Safety and Health Management Department requires subordinate units to conduct root cause analysis and develop improvement measures in response to audit deficiencies. After implementing corrections, they report back to the relevant departments (Operations Departments One and Two or Project Department) and notify the Safety and Health Management Department. The results of the improvements will be presented at senior meetings and concluded. Audits include internal inspections, cross-project audits, and regular or irregular inspections conducted by external supervisory agencies according to annual policies, with results immediately communicated to project units for effective improvement.

Management of Machinery and Equipment and Contractor Management

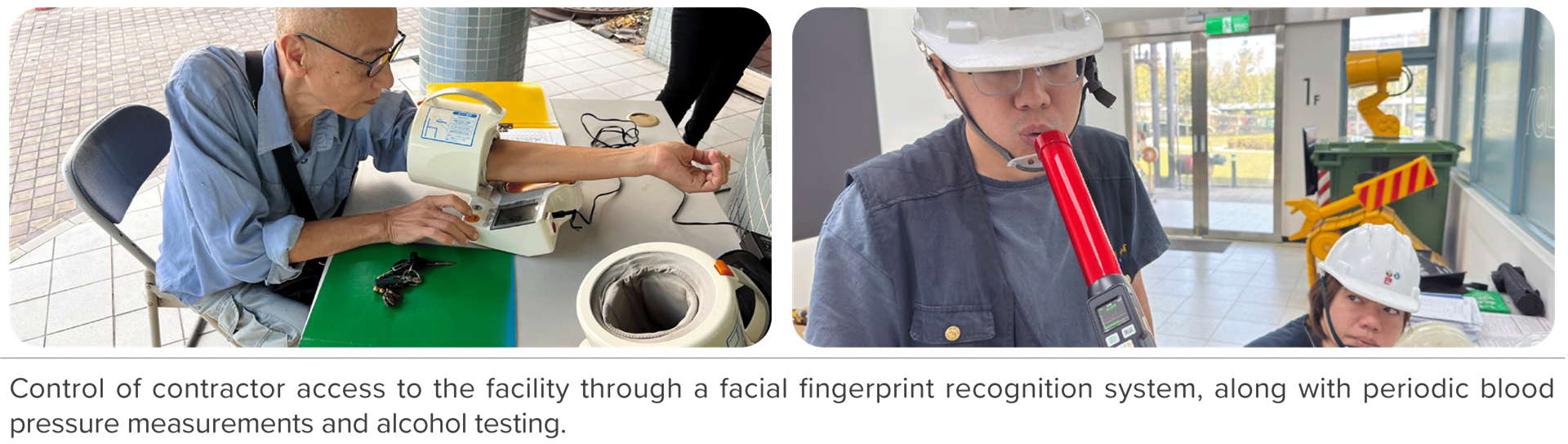

ECOVE ESC enhances machinery and equipment management through the MMIS system, ensuring the safe and stable operation of the incineration plant. Regular inspections of machinery and equipment at each operational incineration plant are included in the schedule, and maintenance and repair tracking are planned through the electronic system to eliminate management oversights. Additionally, an automatic inspection plan has been established, covering pre-operation checks, in-operation observations and audits, and post-operation confirmations, which are incorporated into an evaluation mechanism to ensure the implementation of safety control processes. Through electronic verification of licenses and permits, the qualifications and validity of operators' certificates are effectively confirmed, ensuring operational safety. In terms of project management, ECOVE ESC clearly specifies safety and health regulations and hazard factors in the procurement project specifications and carefully selects contractors. Annual safety and health training is provided to enhance awareness of occupational safety laws and to teach workers how to protect themselves in unsafe situations. Hazard notifications and agreement meetings are conducted before operations, reviewing the equipment and machinery entering the site; daily toolbox meetings and inspections are held during construction, with immediate corrections made for any identified issues. After completion, contractors are evaluated based on the seven major performance indicators of occupational safety, with those rated below D classified as unqualified, ensuring continuous improvement of safety management standards. Each plant employs facial or fingerprint recognition systems for access control, reviewing the qualifications of construction personnel before integrating them into the system. During construction, regular blood pressure and alcohol tests are conducted, and any abnormalities detected result in immediate cessation of work, along with reminders for health management. Vehicle safety and hazardous material management are promoted through JSA analysis during morning meetings, assessing personnel health conditions before operations, adjusting work for those unfit, prohibiting alcohol beverages on-site, and conducting alcohol tests as needed. Vehicle maintenance is managed through the MMIS system, and in 2024, ECOVE WMC's fleet experienced four traffic accidents.

Occupational Hazard Prevention

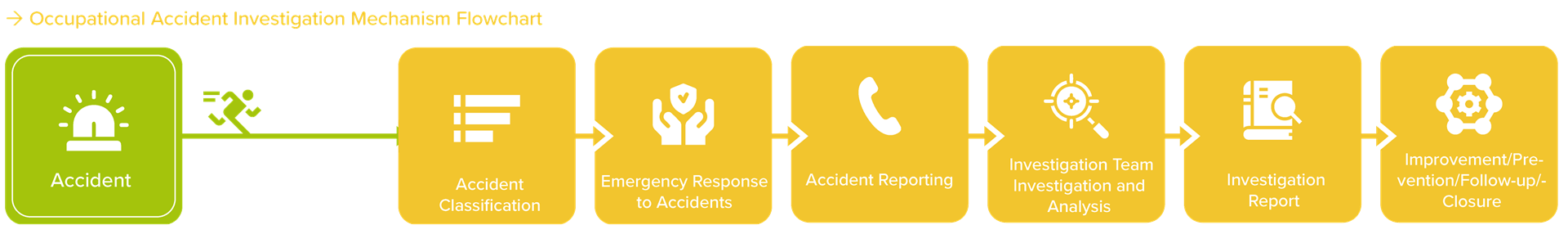

ECOVE conducts a comprehensive review of potential hazards in its operations through risk identification and assessment mechanisms, combining various measures such as education and training, operational safety control processes, and emergency response drills to ensure that employees are equipped to handle potential risks. Additionally, ECOVE strengthens its investigation and improvement mechanisms for occupational accident incidents, ensuring that every event leads to learning and enhancement, further optimizing the safety of the work environment. We believe that a safe working environment is not only the responsibility of the company but also a common goal that all employees strive for together. By continuously promoting safety and health-related plans and systems, the company is committed to creating a disaster-free workplace culture. In the future, ECOVE will continue to invest manpower and resources to provide employees with a healthy and safe working environment, achieving the goal of zero accidents and jointly moving towards a new milestone in corporate sustainability.

For ECOVE and its subsidiaries, providing a safe, healthy, and friendly working environment is the core mission of business operations. "Safety first" is not just a slogan; it is the foundation of daily work for all employees, deeply embedded in every operational detail and internalized as a guideline for action. ECOVE implements safety management through a systematic approach, covering general safety and health education training, specialized hazard education training (such as confined space operations, elevated work, hot work, hoisting operations, etc.), hazard awareness education training, and contractor safety and health education training, providing all employees with comprehensive and effective safety knowledge and skill guidance. In total, 66 emergency response drills, 188 occupational safety-related training sessions, and 4,263 participants were involved in training throughout the year. In addition, the company regularly conducts emergency response drills to simulate various unexpected situations, ensuring that employees have sufficient response capabilities in real dangers. At the same time, supervisors at all levels continuously remind employees of the importance of safety in their daily work, interpreting their commitment to safety through practical actions. To strengthen safety awareness, the company innovatively replaces traditional textual teaching with the sharing of "safety maxims," conveying safety concepts through concise and powerful phrases, embedding a safety culture in the hearts of employees.

Occupational Health Management

Health Check and Comprehensive Health Management: Creating a Safe Workplace

ECOVE values employee health and creates a safe workplace through a robust health management system. New employees undergo health checks, while current employees have regular health examinations every two years, with examination items exceeding regulatory standards. For highrisk operations, such as dust environments, special health checks are conducted annually. In the 2023 health checks, moderate abnormalities and above accounted for 46.6%, with guidance and follow-up provided by healthcare professionals; in 2024, there were no level 3 or 4 abnormalities in special health checks, indicating the effectiveness of protective and monitoring mechanisms.

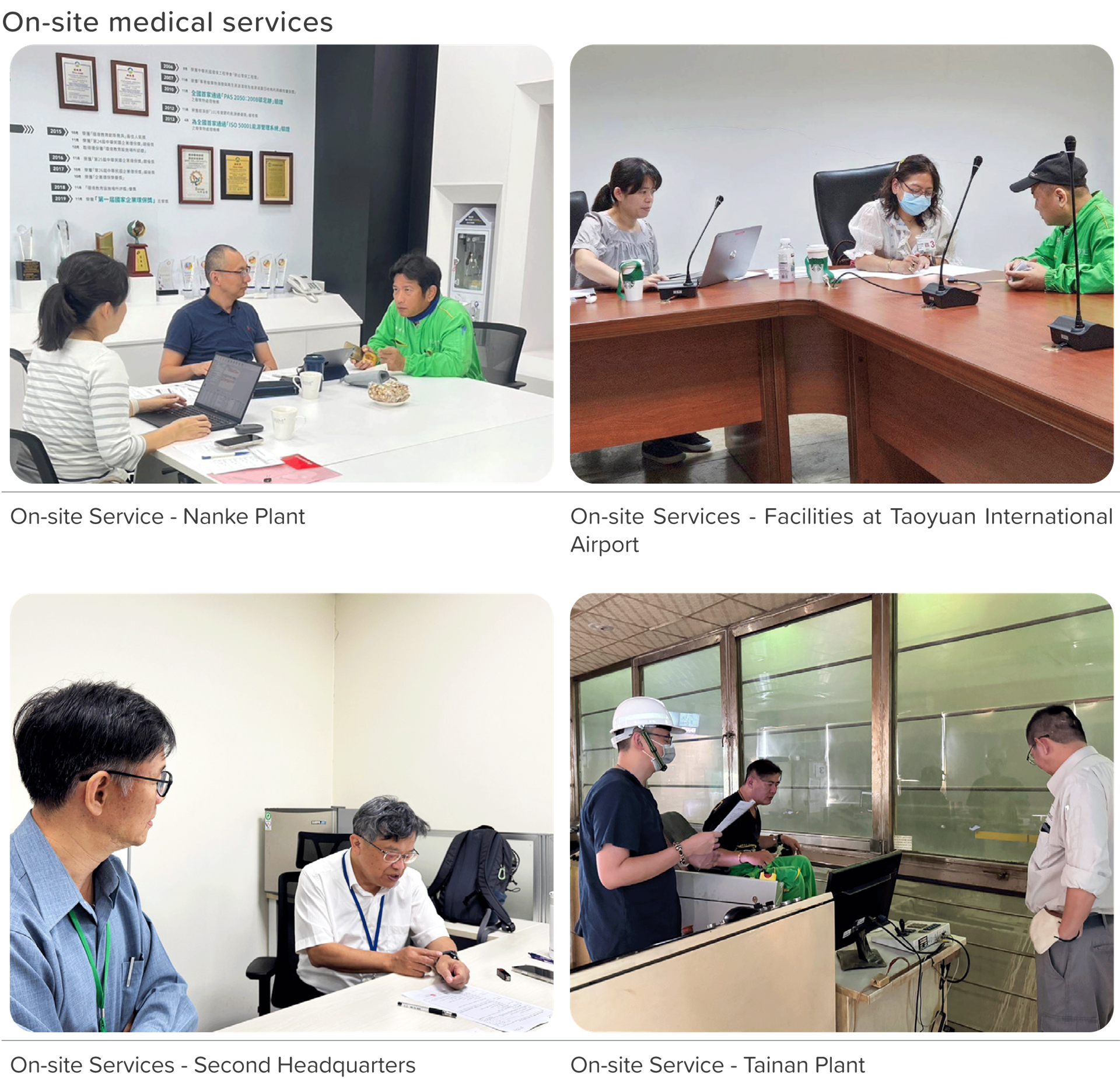

Professional Healthcare Team On-Site, Providing Immediate Health Consultations

The company has dedicated nurses and contracted occupational specialists who regularly provide on-site services at ECOVE and its subsidiaries, conducting hazard assessments at work sites and offering interpretations of health check reports, follow-up care for employees with moderate to severe abnormalities, chronic disease management, and injury tracking services. In 2024, a total of 18 on-site medical service sessions were held, accumulating 48 hours, with 83 individuals consulted, including 3 subjects under maternal health protection. Employees can utilize this free resource to receive guidance on physical and mental health, further enhancing health awareness and self-protection capabilities.

Workplace Health Education: Enhancing Self-Protection Skills

We regularly assess the occupational hazards employees may encounter and conduct relevant training to help employees understand the risks in their work environment, learn how to protect themselves, and reduce health impacts. Additionally, we organize health promotion activities based on regular health check results and common diseases, such as:

- Introduction to Stroke and Hypertension

- Reminding employees to pay attention to hypertension, known as the "silent killer," and learn to quickly identify stroke symptoms.

- Vision Care Seminar

- Guiding employees on how to reduce the adverse effects of prolonged exposure to electronic devices on their eyes through diet, nutritional supplements, and eye exercises.

- Stress Relief, Starting from the Heart

- Continuously promoting the Employee Assistance Program (EAP), publishing articles on stress management, and holding essential oil relaxation workshops to help employees alleviate physical and mental stress.

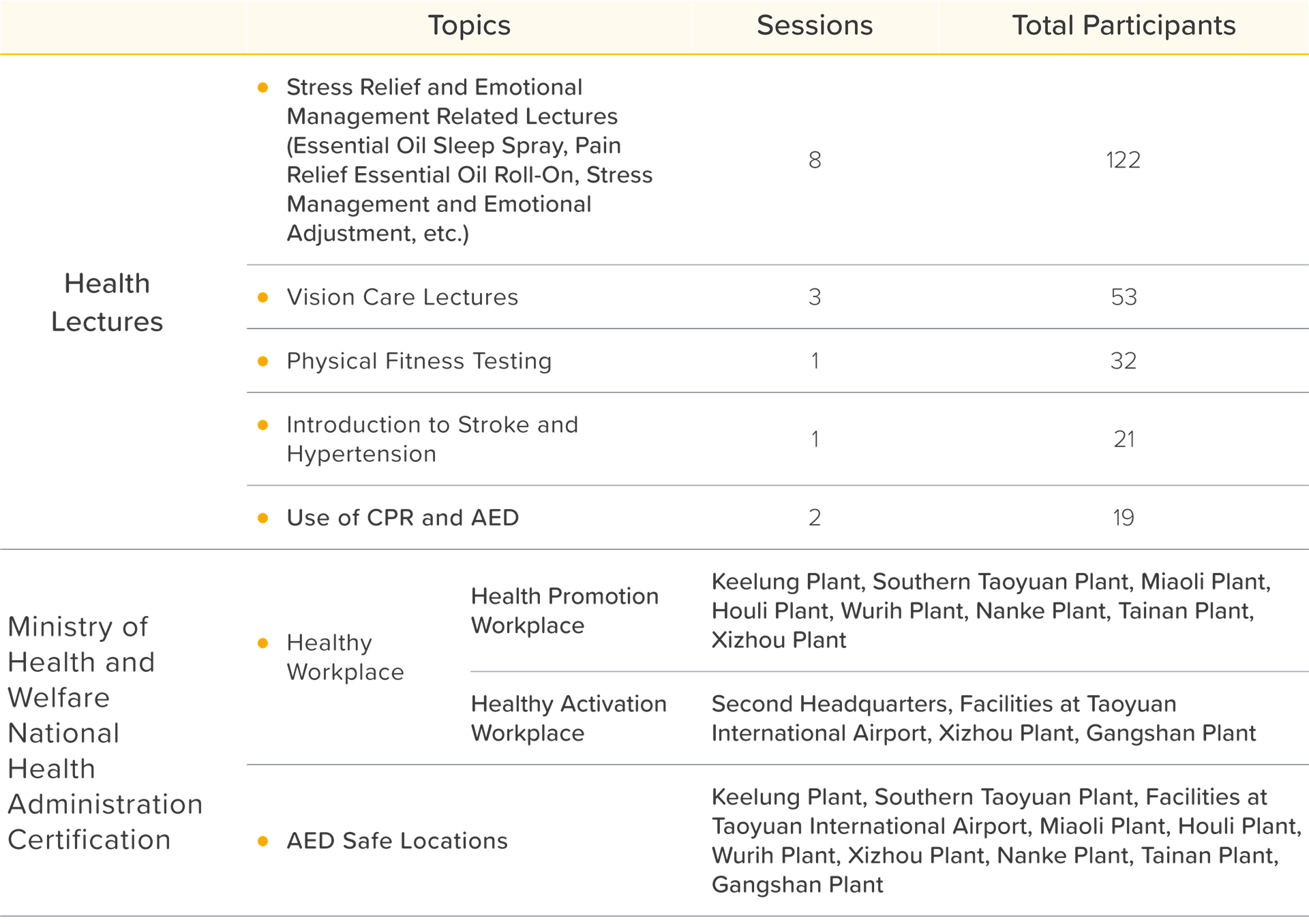

In 2024, we held a total of 15 health seminars, attracting 247 participants, making health management not just a system but an integral part of the corporate culture. Through rigorous health management, professional healthcare support, and ongoing health promotion activities, ECOVE will continue to deepen health care measures, safeguarding the physical and mental health of every employee and creating a safer, healthier workplace environment!

To care for employee health, the CTCI Group has established a "Health Care System Platform," which provides functions such as health knowledge, hospital appointment scheduling for health check-ups, health questionnaire completion, health promotion activities, and medical health consultation registration. We are also committed to promoting the intelligent and systematic "Hygeia Health Management System," which effectively utilizes collected and analyzed health check data to grasp employee health information, report statistics, and risk management. While promoting corporate health and sustainable development, we deeply recognize the importance of health management for contractors. Therefore, we actively collaborate with contractors to ensure that their work environment and employee health receive adequate attention and protection. Our contractor health management measures cover the following key aspects:

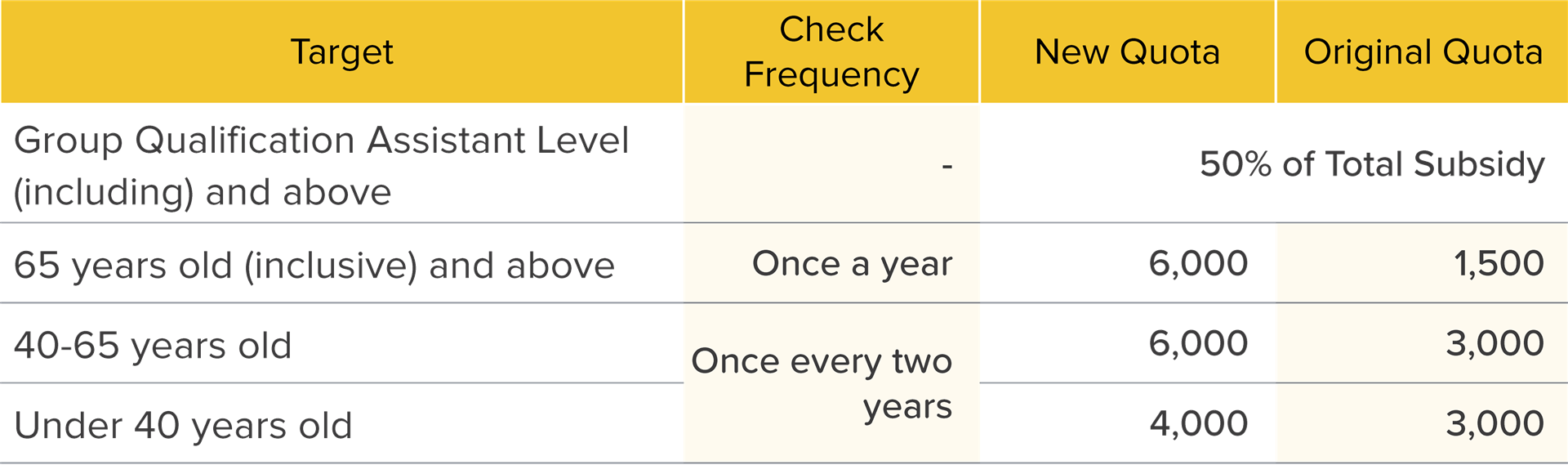

Through these measures, we work hand in hand with contractors to create a safe, healthy, and sustainable work environment, ensuring that every worker can work with peace of mind under health and protection. In addition, we continue to optimize employee welfare measures, allowing every colleague in the ECOVE family to focus on learning and growth without worries. Starting in 2024, we will adjust the health check content based on the needs of different age groups to ensure that health management is more personalized and comprehensive. Furthermore, we will enhance the health check subsidy amounts for employees: those under 40 will see a 33% increase in their health check subsidy every two years, employees aged 40-65 will see a 100% increase every two years, and those aged 65 and above will see a 300% increase in their annual health check subsidy, providing colleagues with more comprehensive health care.

Health Management and Seminars

The health seminars, health certifications, and health promotion activities of ECOVE and its subsidiaries in 2024 are briefly outlined as follows:

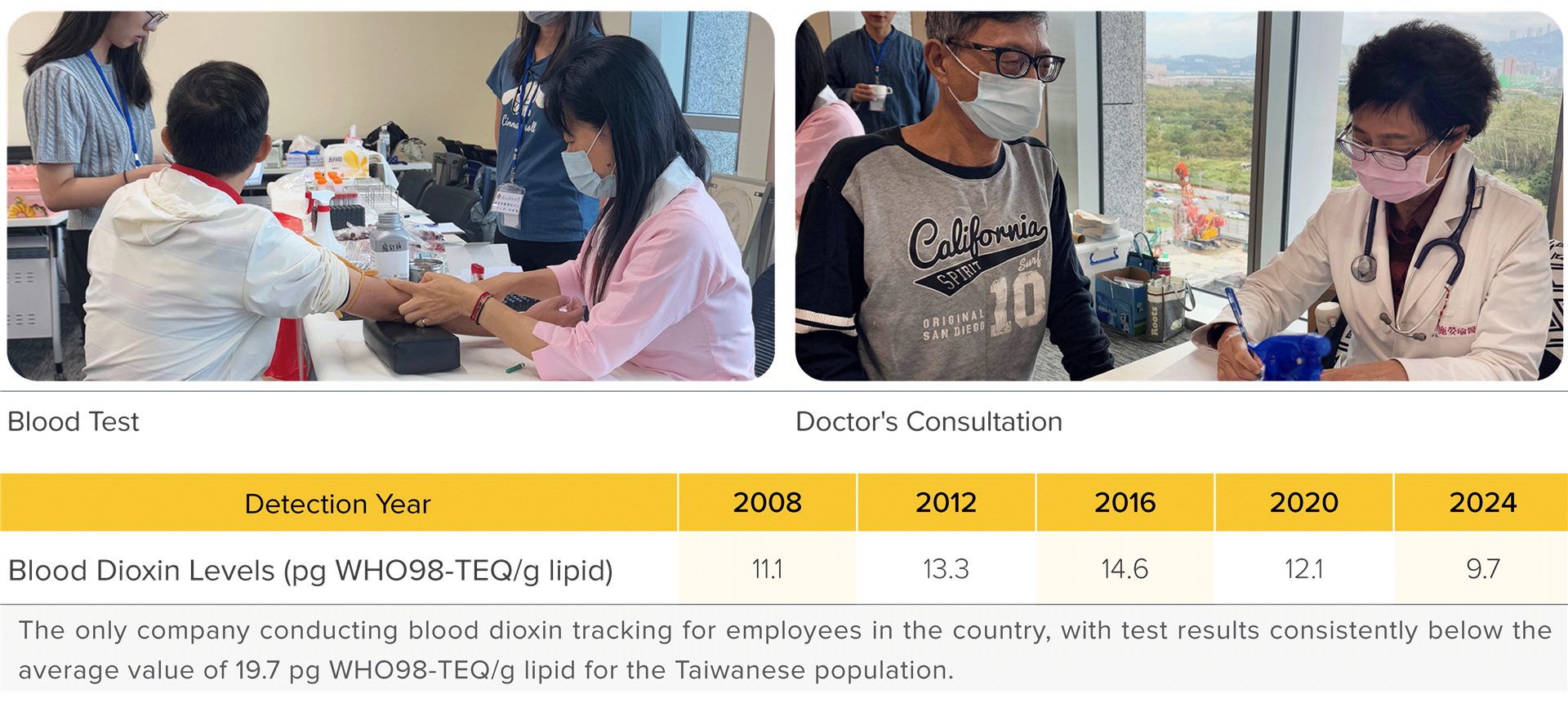

Dioxin tracking and detection - Strictly monitoring the working environment to protect the health of our colleagues!

Since 2008, every four years, the Environmental Trace Toxicology Research Center of Cheng Kung University has been commissioned to conduct blood dioxin testing and tracking for representative employees of the incineration plant, combined with health checks, dietary assessments, and occupational exposure evaluations for analysis. The results show that the dioxin concentration in employees' blood is lower than the average in Taiwan and the recommended values by WHO, reflecting the company's effective measures in air pollution control and employee health protection. As of 2024, five tests have been completed, with the next one scheduled for 2028. Additionally, safety and health training is conducted before annual maintenance work to reinforce the correct use of protective equipment and operational safety, ensuring the health and safety of employees at work.

In 2024, blood tests for polychlorinated dibenzo-p-dioxins/furans were conducted on 38 operators of the company's municipal waste incinerators, with an average value of 9.7 pg WHO98-TEQ/g lipid. This is significantly lower than the average values from previous years, which were 12.1 pg WHO98-TEQ/g lipid in 2020 and 14.6 pg WHO98-TEQ/g lipid in 2016. Additionally, there was no elevated level compared to workers in other metal smelting industries, indicating that the concentration of polychlorinated dibenzo-p-dioxins/furans in the blood of our incinerator operators has not increased due to exposure in the work environment, despite their long-term work at the incinerators. However, polychlorinated dibenzo-p-dioxins/furans are cumulative and may increase with occupational exposure time, improper use of protective equipment, aging of workers, and abnormal dietary habits. Therefore, the company will continue to provide relevant health education to employees. In addition to the correct use of safety protective equipment, we will also emphasize the importance of a balanced diet and regular exercise, and we will continue to monitor the concentration of polychlorinated dibenzo-p-dioxins/furans in workers' blood. In the future, the company will continue to pay attention to the latest news and academic research, and will continuously improve the protective measures for incinerator operators. We will also track the latest developments in related fields to ensure that we provide the most comprehensive health and safety protection for our employees. Through ongoing learning and improvement, we are committed to creating a safer working environment for our staff.

Safety and Health Environmental Series Activities

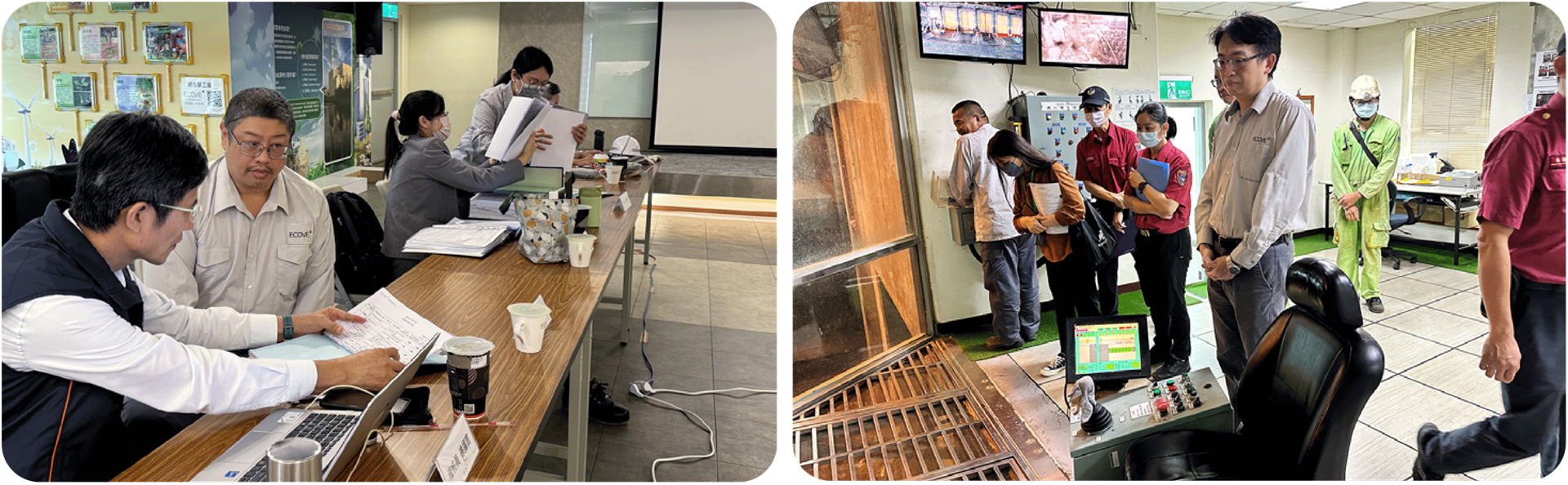

The Safety and Health Environmental Series of activities is held annually. In 2024, we will continue to remind all colleagues of the importance of building a safety consensus, recognizing potential hazards, and implementing safety measures through the safety open letter from the General Manager of ECOVE. Additionally, supervisors at all levels will provide on-site guidance and inspect work safety requirements. Emergency response training will utilize hands-on teaching to immerse colleagues in real situations, helping them understand how to respond when faced with actual emergencies. Management will also continuously engage in safety reflections, proposing innovative or improvement suggestions to achieve the implementation of safety and health practices.

Safety

Chairman's Open Letter: Internalizing Safety Awareness, Implementing Safety and Health Mechanisms, Demonstrating Safety Importance

All management levels personally host safety and health environment meetings

Safety and Health Environment Capability Training

Safety and Health Environment Promotion Meetings(left)、 Employee General/On-the-Job Safety and Health Education Training(right)

On-site Inspections

Emergency Response Drills

Comprehensive Fire Emergency Response Drills(left)、 First Aid and Bandaging Emergency Response Drills(right)

Contractor Safety Management

Contractor Education and Training/Agreement Organization

Regular Safety and Health Environment Training for On-site Supervisors

Operational Safety Control

Technology Application

XR Virtual Reality Application

Contractor Safety Management

Contractor Blood Pressure Measurement (left)、Contractor Toolbox Meetings(right)

Internal and External Safety Audits

ISO 45001 Occupational Health and Safety System Certification(left)、 Joint Inspection by Fire Brigade(right)