ECOVE is Taiwan's first investment holding company with a primary focus on resource cycling as its core business scope. In addition to being committed to technological innovation and actively developing patents, we have established close collaborations with the government, enterprises, and communities over the years. Upholding a corporate culture of being the "most trustworthy," we provide excellent product and service quality. In addition, we forge positive partnerships with suppliers. While pursuing sustainable operation, we also built a sustainable supply chain that co-exist and co-prosper through cooperation with suppliers.

Development, Integration and Application of New Technologies

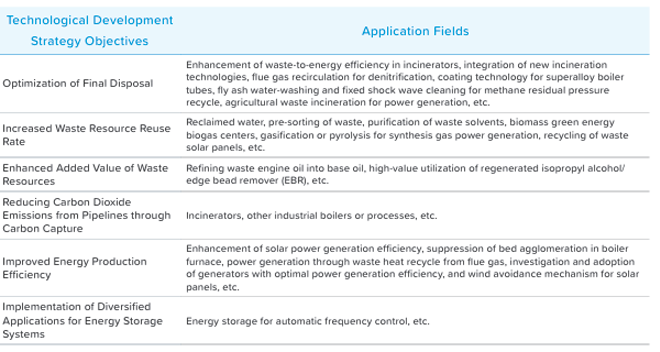

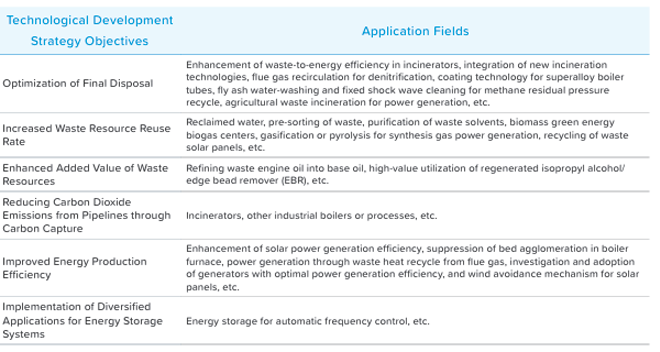

In response to the global trend toward net-zero carbon emissions, ECOVE is actively expanding the synergies of its existing development items. These projects include resource management, renewable energy, recycling and reuse, and electromechanical maintenance and improvement.

In addition, ECOVE is committed to exploring high-value technologies and policy adjustments. Carbon capture technology has been developed through experimentation and simulation to identify key parameters that affect carbon capture efficiency. This technology can also be applied to other industrial sectors for flue gas treatment, helping to reduce the potential impact of climate change. To optimize processing efficiency, increase the value of waste resources, improve energy production efficiency, and implement various applications of energy storage systems.

For example, in the semiconductor industry, ECOVE continues to advance research and development in the recycling and reuse of electronic grade isopropanol (IPA), contributing to sustainable practices within the sector, and has been granted a patent for the invention of the Isopropanol Regeneration System and Process. This process can concentrate the product to a purity level of 99.9% or higher through valorization and will be introduced in the high-tech industry in the future. ECOVE has planned a second phase of process improvements in 2024. The first phase involves replacing the electric boiler of the evaporation and permeation unit with a natural gas boiler for heating. The second phase entails converting the extraction and distillation unit into an evaporation and permeation unit. Upon completion, it is anticipated that the unit carbon emissions can be further reduced by 10%, significantly decreasing the carbon footprint of the IPA product. The Company aims to improve the efficient use of resources through the development, integration and application of new technologies. This will expand the scope of recycling and indirectly reduce reliance on conventional fossil fuels, ultimately contributing to the global goal of achieving net-zero carbon emissions.

Development of Intelligent Management Tools

In response to the global digital transformation of businesses, ECOVE is dedicated to the development of intelligent solutions management, control and maintenance technologies and the implementation of advanced management tools. Through the use of technology automation, our goal is to increase work efficiency and greatly reduce dependence on human labor.

ECOVE has successfully integrated energy storage systems, solar photovoltaic technology, and electric vehicle charging stations to create a smart parking lot with solar charging and energy storage. This initiative is built upon years of rich experience accumulated through efforts in achieving net-zero transformation. Additionally, automated management technologies such as license plate recognition and parking space occupancy detection have been implemented in several large solar photovoltaic parking lots to enhance operational efficiency and the level of intelligence in parking management. The advanced Energy Management System (EMS) integrated within the solar charging and storage system can conduct simulation analyses based on real-time photovoltaic generation, energy storage levels, the status of battery exchange stations, and charging piles. It intelligently optimizes charging and discharging strategies and automatically

adjusts the usage ratios of stored energy, solar energy, and grid electricity, thereby enhancing energy utilization efficiency. In addition, the energy storage equipment is equipped with various sensors that can monitor temperature, smoke, and the concentration of specific gases in real-time. In the event of an

abnormal situation, the fire extinguishing system is activated within seconds, ensuring the safety of both the vehicle and people, and further enhancing the reliability and sustainable value of the system. Through the development and application of intelligent management tools, ECOVE has not only enhanced energy utilization efficiency and site safety but has also provided reliable smart solutions for sustainable urban development.

ECOVE has implemented an automated dispatch system in its waste transportation services. By utilizing AI to assess source requirements and schedule drivers, it is estimated that approximately 780 man-hours per year can be saved. Additionally, the waste collection vehicles are equipped with advanced sensing devices to assist drivers in maintaining alertness and understanding their surrounding environment. The use of driver monitoring systems with on board cameras and sensors powered by artificial intelligence can monitor the condition and behavior of drivers. This proactive approach to driver and vehicle safety improves the prevention of catastrophic consequences that can result from momentary errors, especially during long hours of driving. It contributes to comprehensive, intelligent fleet safety management.

In 2024, the Group established the Smart Innovation Department, which is responsible for the innovative development and design of AI systems for usage in plants. Upholding the Group's synergy, ECOVE has integrated the Group's development results based on operational needs. Currently implemented AI tools, such as conference voice transcription and summary helper, can significantly enhance the efficiency and accuracy when keeping meeting records.

In 2024, the Group's Digital Twin system is officially implemented into the biomass energy plants. This system digitizes all design data, including lists of equipment, pipeline information, instrument configurations, design drawings, vendor documents, and operation manuals, and then integrates them into a 3D

visualization model. This initiative aims to achieve paperless management and significantly enhance data retrieval and management efficiency. Enhancing information retrieval capabilities through digital technology and utilizing 3D visualization techniques to present equipment maintenance status, along with real-time monitoring and visualization functions, enables project managers to quickly grasp engineering progress, ensure the completeness of data at each stage, and optimize operational and maintenance processes. In the future, ECOVE Chiayi Energy Corporation will implement the Group's Digital Twin system when establishing plants, further promoting the development of intelligent management.

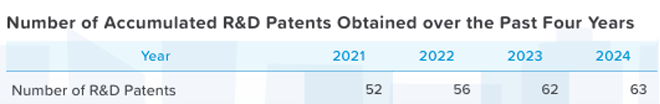

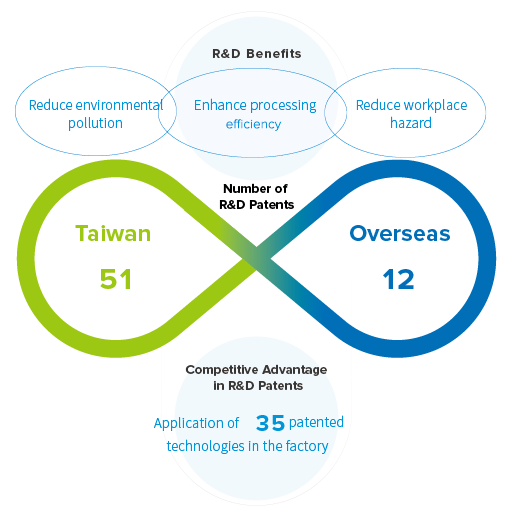

R&D Results - Patented Technologies

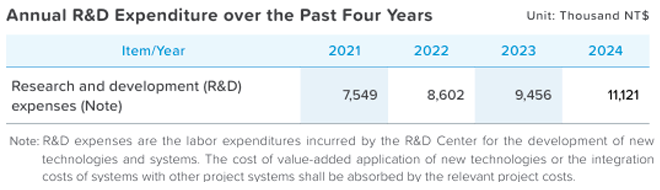

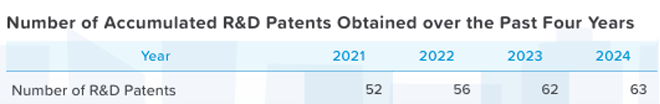

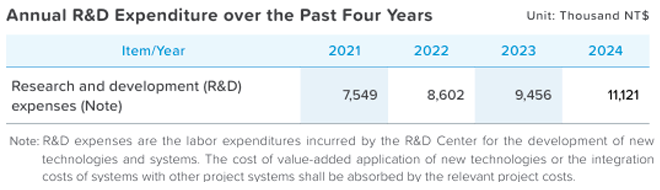

ECOVE fosters innovation and is dedicated to the advancement of new technologies. Over the past four years, our R&D budget has steadily increased, demonstrating our company's strong commitment to technological innovation and our proactive approach to meeting the challenges of the future. Consequences that can result from momentary errors, especially during long hours of driving. It contributes to comprehensive, intelligent fleet safety management. In 2024, the R&D expenditure exceeded NT$11 million. This series of investments will enhance our competitiveness, and the implementation of new technologies will also create new business opportunities.

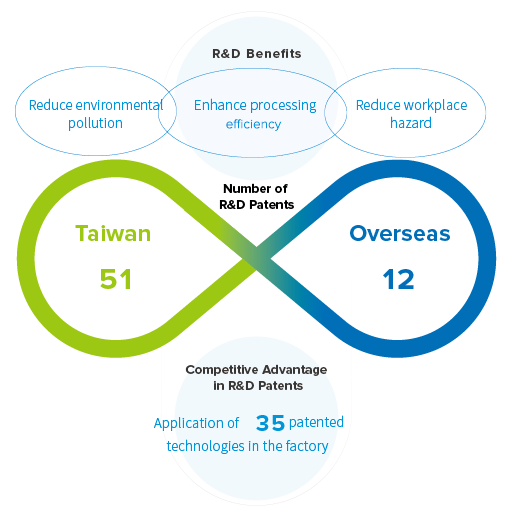

ECOVE places great importance on the management of intellectual property rights, and relevant patent operations are conducted according to standard operating procedures. Additionally, an incentive system is established to encourage innovation among employees. Once the patent certificates are issued, they are publicly disclosed on the company's official website and briefly explained during regular management meetings, highlighting the core content and applications. In 2024, the Company obtained a new patent for the "Acid Removal System Utilizing High-Efficiency Calcium Oxide and Sodium Bicarbonate Reaction Devices in Incineration Plants." Additionally, there are four pending invention patent applications, namely, "Method for Fixed Separation Process of Solar Module Recycling with Flattening and Energy-Saving Features," "Condensation Reduction and Recycling System for Volatile Organic Compounds," "System for Enhancing Fuel Utilization Efficiency of Solid Oxide Fuel Cells Using Membrane Separation Units," and "Recovery System and Method for Edge Bead Remover." Since 2007, a total of 51 domestic patents, 11 patents from Mainland China, and 1 patent from the United States have been obtained by the end of 2024.

The Company also focuses on environmental sustainability and promoting occupational health and safety. Among its research and development achievements, 35 patented technologies effectively improve incinerator operation, exhaust gas treatment and recycling and reuse efficiency, thereby reducing environmental pollution and providing a competitive edge to improve operational performance.

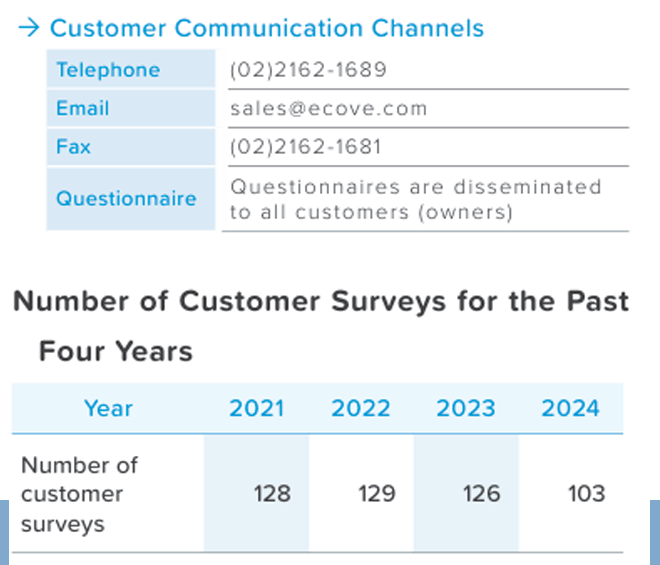

Service Quality

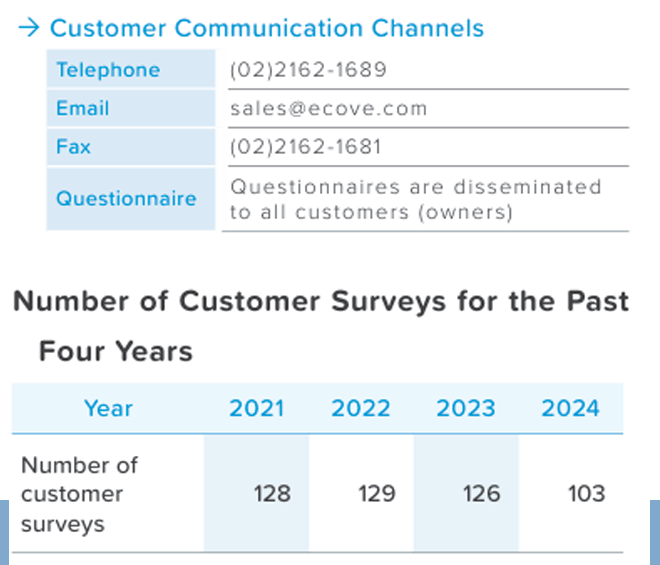

ECOVE has established a comprehensive and systematic service quality management process to ensure that every service meets

international standards and satisfies customer needs. The Company adheres to a customer-centric philosophy, providing clients with diverse communication channels such as telephone, surveys, and project follow-ups to gain a deeper understanding of customer needs.

Additionally, the Company proactively sends out surveys annually to the responsible personnel and their supervisors of ongoing projects for feedback, incorporating customer opinions into improvement plans.

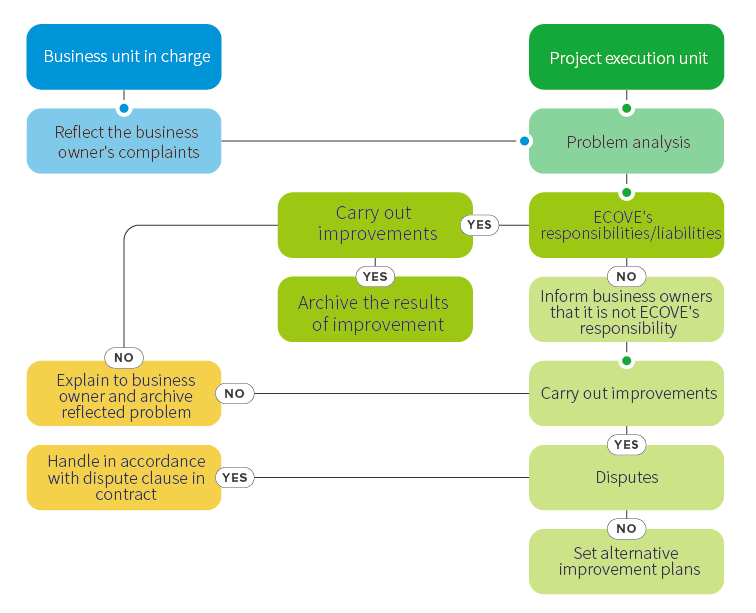

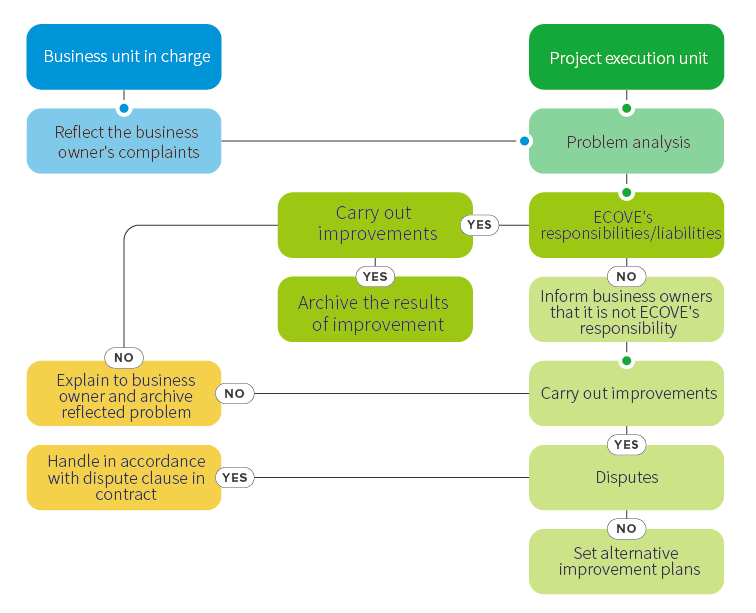

In response to the relevant suggestions put forth by our clients, we have established a comprehensive process for handling customer feedback, ensuring timely responses to our clients. We require the executing units to conduct a careful and thorough analysis of the root causes of issues, propose improvement plans and processes, and enhance the general quality of customer service. In 2024, we received 23 pieces of feedback from questionnaires, primarily praising our personnel for their execution of projects. For example, they actively participated in the Company's circular economy project meetings, completed engineering tasks on time and with quality, demonstrated high levels of cooperation, and received local recognition for their diligence and effective communication with relevant agencies. Additionally, there were clients of construction projects who suggested that the Company strengthen communication and coordination with the owners,

increase the owners' work tasks that the Company can assist, and reduce interface coordination with other vendors during maintenance periods to improve efficiency. The project personnel have been informed internally, and follow-up improvements have been confirmed. In 2024, there have been no verified complaints regarding violations of customer privacy.

Surveys of Customer Satisfaction

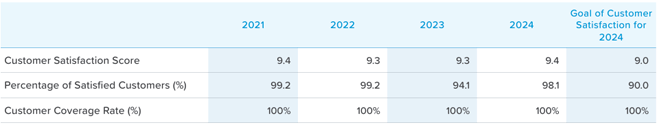

To ensure that our service quality meets customer expectations and needs, ECOVE conducts an annual customer satisfaction survey in accordance with the subsidiaries' Enhancement of Customer Service Operation Management Guidelines. This survey serves as the basis for improving our service quality. The survey covers several aspects, including occupational safety and health, work quality, execution efficiency, communication and coordination, work attitude, and professional expertise, etc. In the survey with a maximum satisfaction

score of 10 points, the average score obtained in the 2024 assessment was 9.4 points, exceeding the annual target of customer satisfaction of over 9 points. In this context, we define a score of 7 or above as satisfactory. In 2024, the number of satisfied customers reached 98.1%, exceeding the target value of 90%.

Sustainable Supply Chain Management

With the vision of "The most reliable provider of industry-leading ‘resource cycling’ services", ECOVE, as Taiwan's largest environmental resource management company, plays an important role in helping supply chain vendors to move towards sustainability by promoting and implementing sustainable supply chain management, so as to cope with future risks and opportunities, and enhance their sustainability.

Overview of Supply Chain

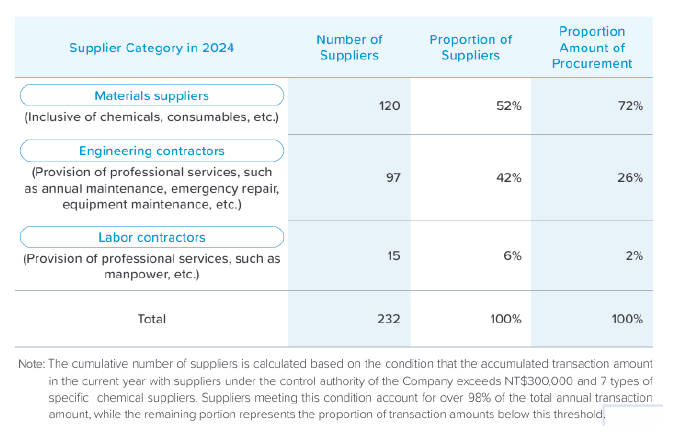

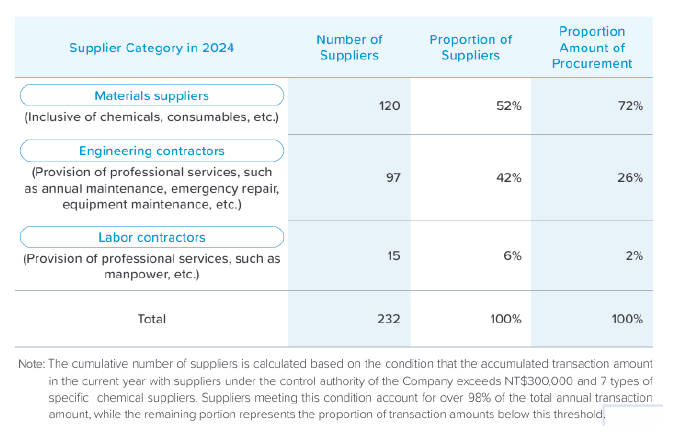

In order to provide better service quality, our supply chain vendors are primarily classified into three major categories: equipment suppliers, engineering contractors, and labor contractors. These major categories of vendors provide the necessary equipment, materials, maintenance assistance, improvement project implementation, and manpower support for ECOVE's operational facilities and stations. This includes various

equipment parts, consumables (including chemicals and disposable supplies), and service providers for major maintenance, emergency repairs, equipment inspections, and labor workforce. By collaborating with various suppliers and contractors, we ensure stable operation of ECOVE's daily maintenance and successful completion of various project works. The number of manufacturers and the annual procurement amount indicate that, in addition to routine equipment maintenance materials and operational consumables, ECOVE's major procurement expenses are primarily focused on maintenance, updates, and repairs to keep the equipment running smoothly and on project contracts.

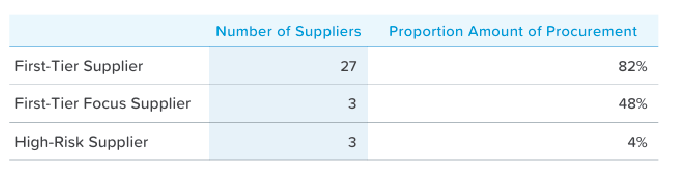

To effectively manage our suppliers, we have further categorized them into tiers. Suppliers that account for the top 80% of annual cumulative transaction amounts, with transactions exceeding NT$300,000 and involving seven types of specific chemical products (quicklime, sodium bicarbonate, activated carbon, cement, chelating agents, urea, and ammonia water), are classified as first-tier suppliers. Among these, suppliers with an annual cumulative transaction amount exceeding US$3 million are designated as first-tier focus suppliers. Those identified as high-risk suppliers following the SAQ questionnaire assessment will be subject to on-site audits and control measures.

Supply Chain Sustainability Development Strategy

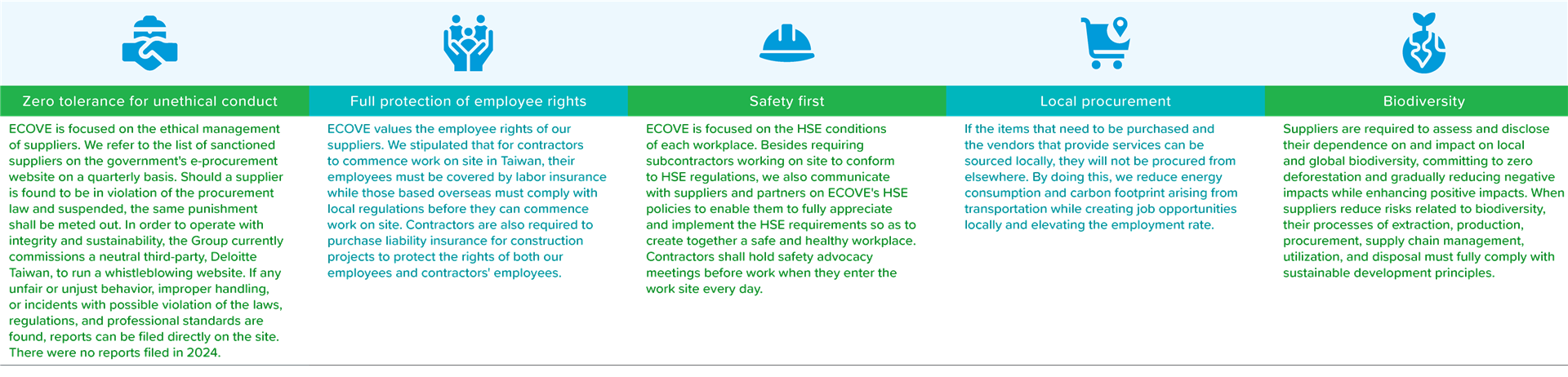

In accordance with the sustainable development strategy of the supply chain of the Group's parent company, CTCI, ECOVE has invited suppliers to join us in our sustainable development strategy in the five aspects of "zero tolerance for unethical conduct", "full protection of employee rights", "safety first", "local procurement" and "biodiversity". We manage vendors' information through the supplier and subcontractor section of CTCI and also provide a whistleblowing platform, thereby establishing a comprehensive communication mechanism:

Strengthening the Culture of Sustainable Supply Chain Management

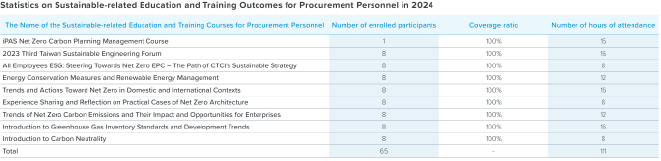

In order to improve the procurement team's understanding of sustainability issues, ECOVE actively organizes sustainability training for its employees. These training courses are tailored to the specific needs of the company and aim to increase the awareness and expertise of employees in the area of sustainability and to enable them to apply this knowledge in their daily procurement activities.

Supplier Code of Conduct and Vendor's Commitments to Corporate Sustainable Management and Net Zero

ECOVE is actively committed to promoting corporate social responsibility and developing partnerships. We adhere to the principlesoutlined in the United Nations Global Compact, Universal Declaration of Human Rights, and the UN Framework and Guiding Principles on Business and Human Rights. In line with these standards on human rights, labor practices, environment, and anti-corruption, we have established the "ECOVE Supplier Code of Conduct." It is applicable to all suppliers, their subsidiaries, affiliates and contractors, and ECOVE continuously requires suppliers and contractors to comply with sustainable standards related to labor and human rights, health and safety, environment, ethical practices and management system. The code applies to all suppliers, including their subsidiaries, affiliated companies, and contractors, who provide goods or services to ECOVE. It mandates that all their business activities, including those of their subsidiaries, affiliated companies, and contractors, fully comply with the provisions of the code as well as with the applicable laws and regulations in their respective jurisdictions.

Meanwhile, ECOVE formulates the "Vendor's Commitments to Corporate Sustainable Management and Net Zero," and the Company has been requiring all new suppliers to sign the agreement since 2023. Alongside maximizing shareholder benefits, ECOVE also prioritizes the rights and interests of relevant stakeholders, adheres to socially recognized ethical norms, and promotes net zero emissions to address the impact of climate change and mitigate global warming. The Company aims to work collaboratively with all stakeholders to create a fair and equitable society and a sustainable living environment.

In terms of practical management, all contracts include the clause "The contract may be terminated or rescinded at any time by the Company if Party B has violated its corporate social responsibility policy and has caused a significant negative impact on the environment and society" to reinforce the actual implementation of the undertaking of social responsibility.

Sustainable Supply Chain Management Mechanisms

Sustainability Risk Survey

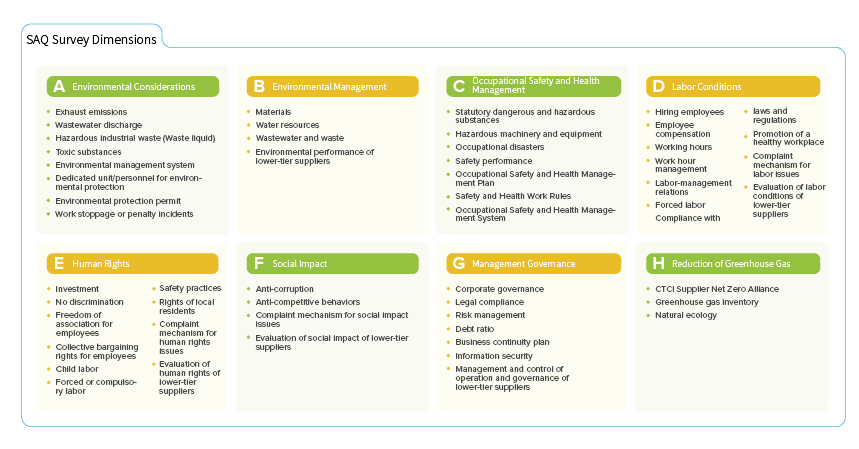

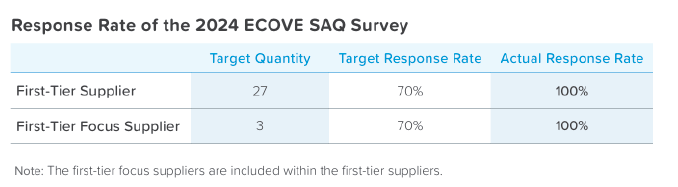

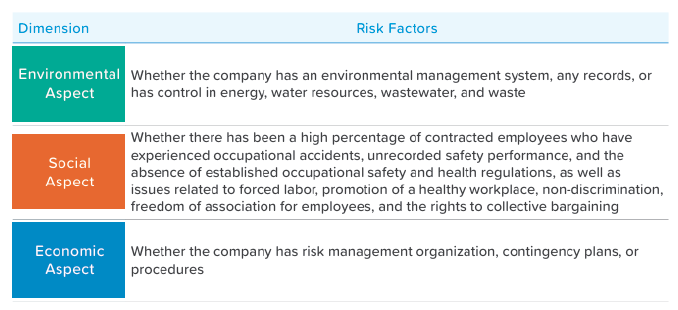

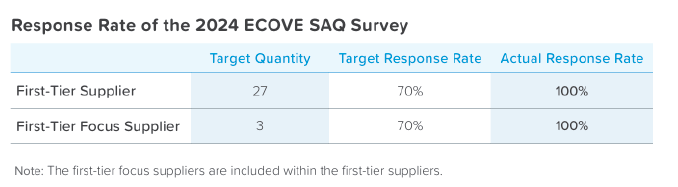

In order to assess the sustainability risk situation of suppliers and the implementation level of sustainable practices, ECOVE has issued a self-assessment questionnaire (SAQ) on sustainability risk to first-tier suppliers. Through an investigation across eight dimensions, the potential risks of suppliers are identified. Based on the scoring results, suppliers who score below 50 points and fall within the lowest 5% among all suppliers are classified as high-risk vendors. Subsequently, on-site visits are arranged for these high-risk vendors to help them understand the importance of the survey items and provide improvement suggestions, such as avoiding the placement of clutter near fire safety equipment and promoting the conservation of water resources, in order to further manage risks.

The 2024 SAQ assessment results indicate a total of three high-risk suppliers. The assessment dimensions and risk factors are detailed in the table below. For the aforementioned suppliers, on-site audits are scheduled to be conducted in 2025; we require suppliers to address deficiencies and providing guidance and improvement recommendations.

Establishment of Supplier Sustainability Capabilities

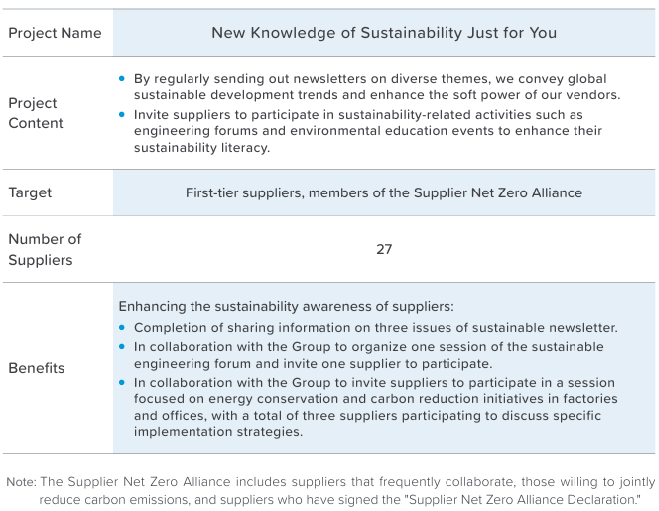

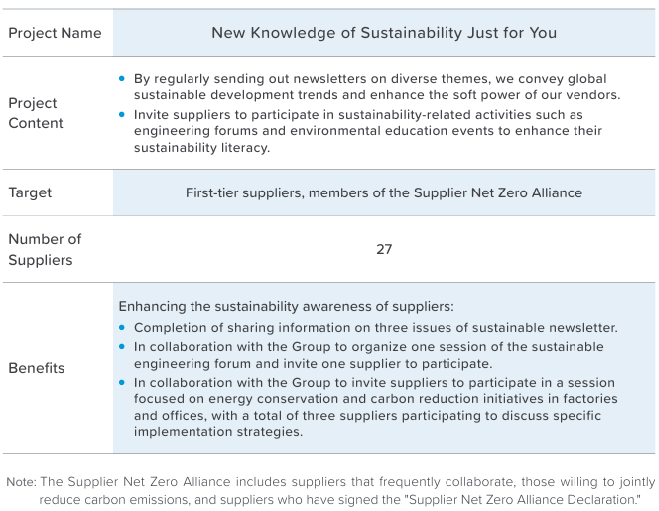

To implement the management and control of sustainability risks among suppliers, the CTCI Group hosted

the "2024 Fourth Taiwan Sustainable Engineering Forum" in December 2024. The theme of the forum is "Sustainable Future - Artificial Intelligence * Natural Solutions * Sustainable Talent." Renowned experts and scholars, as well as key engineering and technical service providers, were invited to participate. The forum featured keynote speeches addressing trends related to COP29, ESG, and other topics, as participants

explore new international sustainability trends and collaboratively creating value chain impact.

To enhance suppliers' performance on ESG issues, ECOVE actively invites suppliers to participate in sustainability-related activities such as the Sustainable Engineering Forum, lectures, and sustainability newsletters. We continue to communicate and engage with suppliers to strengthen their sustainability literacy, promoting and deepening our concept of sustainable net zero throughout the supply chain.

In addition, regarding suppliers of equipment and facilities, ECOVE plans to collaborate with external consultants in 2025 through a government guidance program to assist suppliers in conducting greenhouse gas inventories and providing recommendations for energy conservation and carbon reduction. For subcontractors, ECOVE's carbon seed personnel will assist suppliers in conducting greenhouse gas inventories and providing recommendations for energy conservation and carbon reduction, with the aim of significantly enhancing the suppliers' capabilities in sustainable carbon reduction.

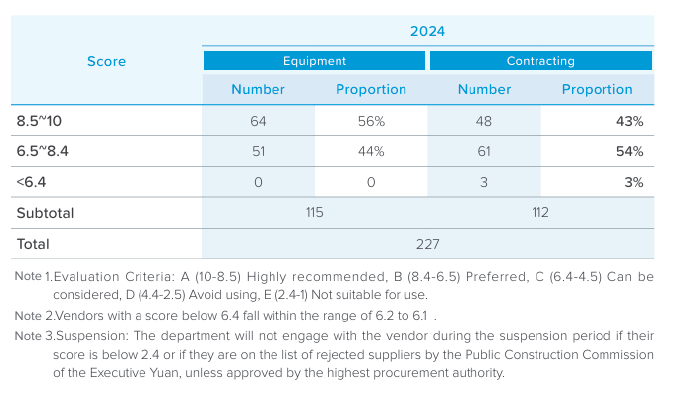

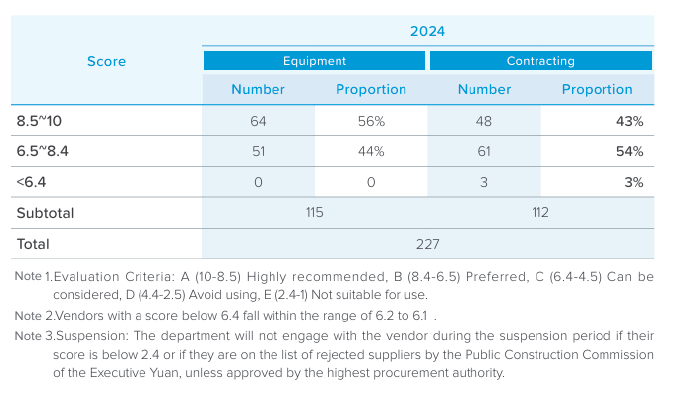

Supplier Performance Evaluation and Audit Guidance

To assess the risks and competitiveness of the supply chain, ECOVE has established a mechanism for supplier evaluation, audit, and guidance. The evaluation, assessment, and audit of supplier and contractor supply and execution quality are conducted by cross-departmental teams comprising the Procurement Center, project managers, the Occupational Health and Safety Management Department, and on-site team leaders. These teams evaluate and assess the quality of supply and execution by suppliers and contractors. On top of listing the quality of suppliers and contractors, costs, service standards, environmental protection, OSH, and technologies into the evaluation items to ensure their quality standards and safety and health, we also uphold the spirit of PDCA, requiring suppliers and contractors to rectify their deficiencies, and we provide necessary guidance in a timely manner, so that ECOVE's supply chain can maintain the best competitive state and mitigate the risk of operational disruptions. For equipment and material suppliers, a comprehensive evaluation is conducted to assess their commitment to compliance, delivery control, product quality, defect handling, and any disputed matters. This evaluation aims to examine the overall service and quality provided by the suppliers and serves as a basis for incentivizing them and providing improvement recommendations.

Contractor Visit and Communication

As the COVID-19 pandemic subsides in 2023, the supply of essential chemical agents for incineration plants has been properly arranged, and the risks associated with procurement and storage have gradually decreased. In addition to the evaluation of the contractor's construction results conducted by the supervisors from various units, the Company also enhances its positive influence on suppliers through procurement strategies.

In 2024, the Company conducted on-site visits and in-depth discussions with key equipment suppliers and subcontractors. Through the process of factory inspection, a total of 30 evaluations and audits of contractors were conducted. The audit content covered aspects such as quality, safety, and compliance with regulations, and further guidance was provided to the vendors to implement corporate social responsibility policies. The evaluation results will serve as an important reference for future procurement and contracting decisions.

In the future, the Company will continue to engage in diverse interactive methods to gain a deeper understanding of the internal operations of suppliers and contractors, and to ensure that their quality management meets the established standards. For example, site visit inspections when key equipment is sent out for maintenance, inspection of customized equipment and materials prior to delivery, and on-site operation audit during annual maintenance will be conducted by quality control and safety and health teams. Through on-site inquiries and visits, we propose recommendations and assist in improvements to enhance the management and execution capabilities of our partners.

In addition, for the development of new suppliers, the Company conducts a comprehensive evaluation through on-site visits. This evaluation includes assessing contracting and management capabilities, facility conditions, manpower allocation, material management, quality control, and warehouse management. These assessments serve as a reference for trial orders and subsequent collaborations,ensuring supply chain stability and overall operational efficiency.

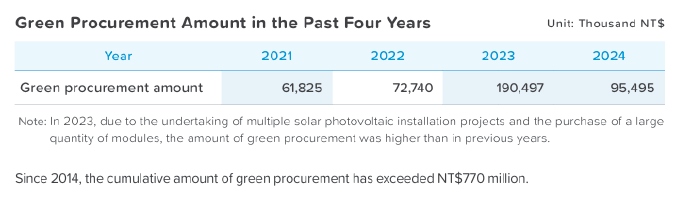

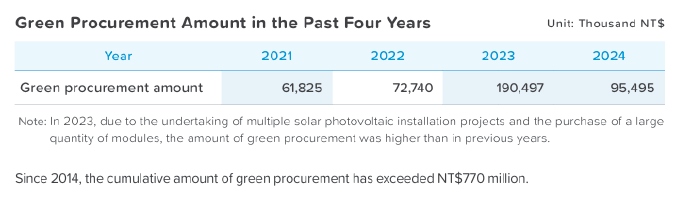

Green Procurement

ECOVE recognizes green procurement and green consumption as essential core values in promoting sustainable development within the Company. In response to the policy on green consumption, the concept of the green living circle has been introduced into the Company. This includes implementing green procurement of environmentally friendly products that are "low-pollution, energy-saving, and recyclable," as well as adopting other green services in daily life, such as green office environments and green transportation. In both production and daily life, ECOVE aims to achieve energy efficiency, carbon reduction, and a love for the Earth as sustainable development goals.

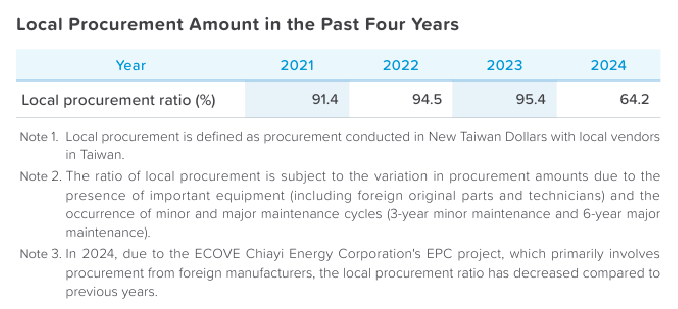

The major operating bases of ECOVE are all located in Taiwan; ECOVE implements the local procurement policy in compliance with the parent company's sustainable supply chain development strategy. We believe that local procurement is conducive to local economic development and can minimize the negative impact on the environment by reducing carbon emissions from transportation. Except for special machinery components, ECOVE strives to source locally without affecting the stable operations, safety, and fairness of procurement. We screen local vendors with potential for the re-engineering of worn parts and equipment and provide them the opportunities to win trial orders and improve autonomy. The spare part engineering is mostly contracted to local vendors to reduce carbon emissions and waste and to create local employment and business opportunities.