Environmental Performance

Waste Collection and Management

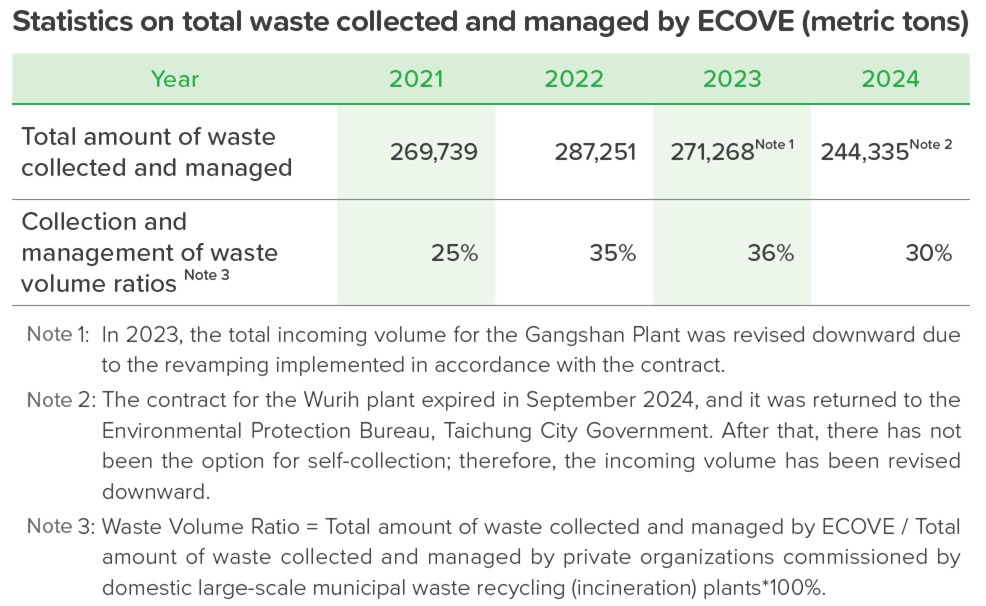

ECOVE Waste Management Corp. provides waste collection and transportation, as well as waste incineration residue removal services. The number of customers it served exceeds 22,000. In 2024, the total amount of waste collected and managed by ECOVE was 244,355 metric tons, which accounted for 30% of the total amount of waste collected and managed by domestic large-scale municipal waste recycling (incineration) plants on behalf of private organizations. To effectively manage waste quality, ECOVE utilizes an intelligent management system that screens vendor qualifications, approves waste types, establishes and stores entry data, and performs real-time monitoring of entry information. Through the analysis of entry statistics, waste quality is effectively controlled. In 2022, the management system was further optimized by adding functionality to interface with the declaration system of the Ministry of the Environment. This allows for the rapid and accurate upload of data to the regulatory center, ensuring legal compliance and reducing redundant work. In addition, the environmental protection laws and regulations/entry management information can be updated and announced immediately, and the management system can be introduced into each energy from waste plant to establish a list of unsuitable wastes or manufacturers, so as to strengthen the management of energy from waste plants, and at the same time, analyze the characteristics of wastes in each area to enhance the efficiency of incinerator combustion. The decrease in the ratio of waste management received in 2024 is attributed to the expiration of the contract for the Wurih plant in September 2024, along with the commencement of operations at the Taiwan Cement Corporation (TCC) DAKA Renewable Resource Recycling Center (RRRC) and the Taoyuan Biomass Energy Plant.

To enhance incineration efficiency, maintain processing effectiveness, and ensure the safety of waste removal vehicles entering the facility, ECOVE Waste Management Corp. conducted on-site guidance and inspections for business units and waste removal organizations in 2024, auditing a total of 47 business units and 1 waste removal organization. Through audits, the company checked the quality of the production process, the output and storage conditions of waste, the clearance permit deadlines, and the proper operation rates of waste transport vehicles. Additionally, we promote relevant environmental regulations and the management specifications for the entry and exit of energy from waste plants, providing recommendations for optimizing waste management.

The audit results indicate that all 12 business units that previously violated the incineration plant's entry regulations have completed improvements following guidance. An investigation was conducted on the waste output and disposal conditions of 29 business units. Three business units require enhanced awareness campaigns and further investigation. One business unit needs to have the waste it generates further analyzed and conduct sampling tests. Additionally, two business units underwent on-site inspections due to concerns regarding the waste entering the facility. Among them, the waste testing from Li Sing Environmental Co., Ltd. revealed the presence of PVC components, and the chlorine content exceeded the acceptable standards; therefore, their application for entry was rejected. In addition, the inspection agency reviewed one business unit and found no areas requiring improvement. Through this guidance and audit, we ensure that the business units and disposal organizations comply with environmental protection regulations, enhance waste management efficiency, and maintain the stable operation of the incineration plant.

To enhance the efficiency of waste collection operations, a waste collection dispatch management system was introduced in 2021. This system digitized traditional paper-based operations such as vehicle dispatch management, driver management, and vehicle management. This not only reduced paper usage but also improved operational efficiency and decreased the burden of manual tasks. In 2023, further optimizations were made, including the addition of features for warnings on abnormal results of alcohol testing, attendance anomalies, and API reporting, aimed at enhancing safety management and improving the accuracy of reported weights. In 2024, based on feedback from the user units and the waste collection drivers, continuous system optimization and adjustments were carried out to enhance operational convenience and overall management efficiency.

Energy from Waste Performance

ECOVE Environment Service Corp., a subsidiary of ECOVE, focuses on the operational management of energy resource centers (waste incineration power plants and biomass energy centers). It converts high calorific value waste into electrical energy through incineration technology, while low calorific value waste is processed through advanced anaerobic fermentation to generate biogas for electricity production, which is then resold as one of Taiwan's sources of electricity. This process not only reduces dependence on fossil fuels but also effectively decreases the environmental pollution caused by waste landfill. ECOVE Environment Service Corp. utilizes optimal operational techniques to enhance energy conversion efficiency, ensuring the maximization of waste resource utilization benefits while simultaneously reducing waste, emissions of exhaust gases, and wastewater discharge. The company actively implements its mission of "optimizing resource recycling efficiency" to promote sustainable environmental development.

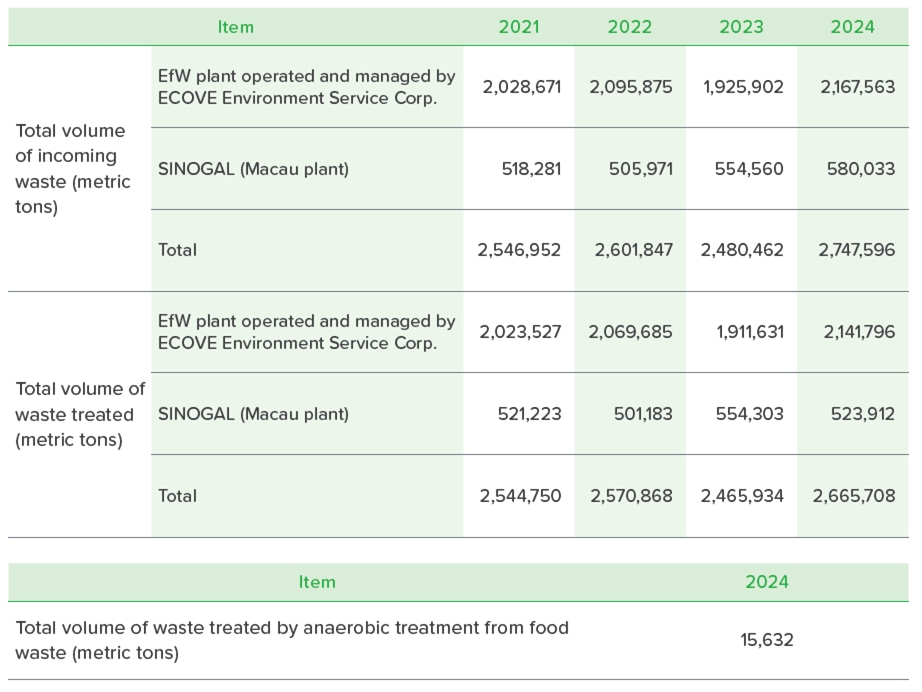

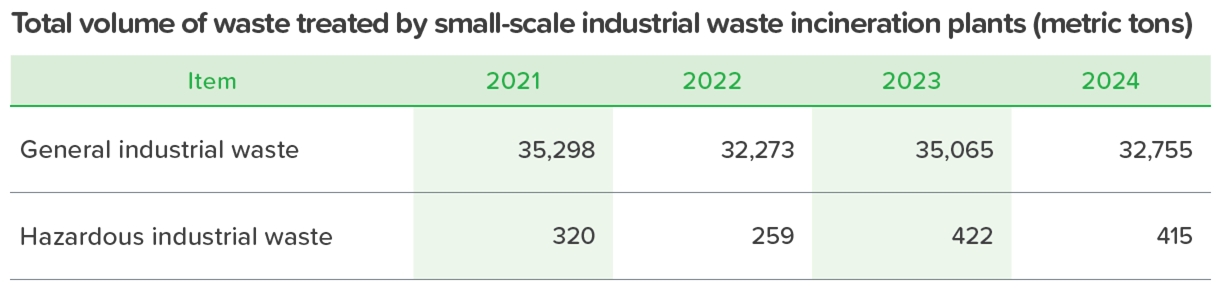

Currently, ECOVE Environment Service Corp. manages a total of nine large energy resource centers in Taiwan , which include a biomass energy center equipped with anaerobic digestion facilities from food waste, as well as two small-scale industrial waste incineration plants. The company undertakes operations for nine local environmental protection bureaus and government agencies. In 2024, the total amount of waste entering the large-scale energy resource centers (general waste and general utility waste) was 2,167,563 metric tons, and ECOVE Environment Service Corp. accounted for 34.32% of the total amount of waste entering the plant in Taiwan. The energy resource centers reported that the total amount of general waste was 1,568,036 metric tons, accounting for 72.34% of the total incoming volume; the amount of general industrial waste was 599,527 metric tons, representing 27.66% of the total incoming volume. According to the latest statistics released by the Ministry of Environment, the average waste generated per person in Taiwan is approximately 1.36 kilograms per day. Of this amount, 35.77% is processed through incineration. The processing volume at ECOVE Environment Service Corp. corresponds to the annual waste generation of approximately 8.83 million people. In 2024, the anaerobic treatment volume from food waste reached 15,631.93 metric tons. Additionally, in 2024, the incineration capacity for general industrial waste at small-scale incineration facilities was 32,755 metric tons, while the processing volume for hazardous industrial waste was 415 metric tons, which constitutes 0.015% of ECOVE Environment Service Corp.'s total processing volume. The total amount of waste processed through energy recovery incineration and food waste treatment is 2,681,340 metric tons.

In addition to Taiwan, our waste incineration services have also expanded overseas, with our subsidiary SINOGAL undertaking general waste disposal business in the Macau region. With a local population of approximately 700,000 people, the total intake of waste in 2024 was 580,033 metric tons, of which general waste accounted for 421,431 metric tons, representing 72.66% of the total, and general industrial waste accounted for 158,602 metric tons, representing 27.34% of the total. Based on the average of the past four years, the annual average total intake was 539,710 metric tons, and the average total processing quantity was 525,155 metric tons.

1 9 large-scale energy resource centers including Keelung Plant, Southern Taoyuan Plant, Biomass Plant, Miaoli Plant, Houli Plant, Wurih Plant, Xizhou Plant, Chengxi Plant and Gangshan Plant. 2 The main source of data is from the Solid Waste Incinerator Management System (SWIMS) of the Environmental Management Administration, Ministry of Environment. Based on the total waste intake of 6,314,882 metric tons from 27 waste energy from waste plants plants in Taiwan in 2024.

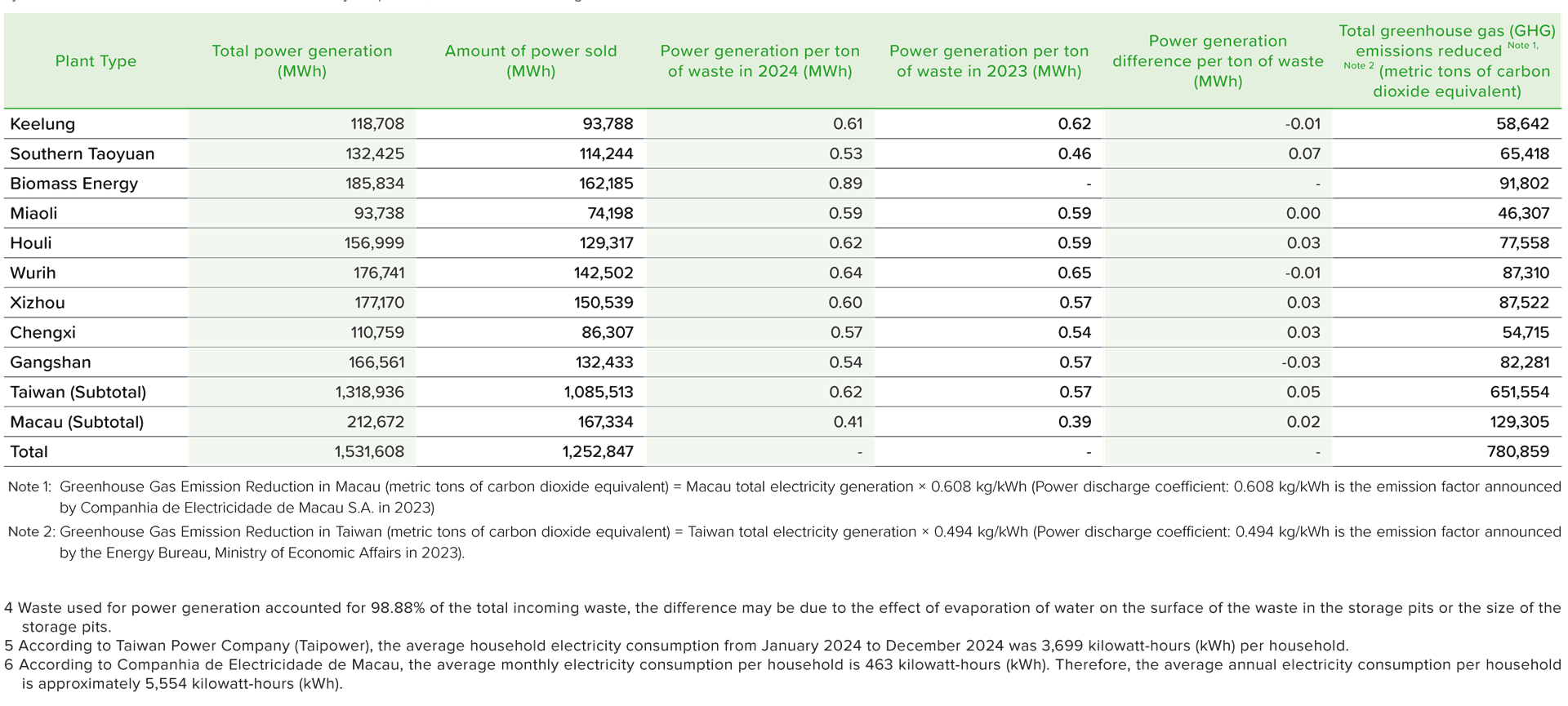

■ Energy-from-Waste Power Generation

The energy from waste plants operated and managed by ECOVE Environment Service Corp. (including Macau and excluding the two small plants (no power generation)) not only treat waste, but also generate electricity from the heat generated by incinerating waste. The percentage of waste-to-energy power generation is 98.8%. In 2024, a total of 2,665,708 metric tons of waste was incinerated , generating a total of 1,531,608 MWh of electricity. After deducting the incineration plant's self-consumption, the total amount of electricity to be sold back to the power company was about 1,252,847 MWh, which means that 81.80% of the total amount of electricity generated will be exported to the power grid. The electricity to be sold back in 2024 can supply the annual electricity consumption of approximately 290,000 customers in Taiwan and 30,000 customers in Macau . With the electricity generated from the incineration plant, a total of about 780,900 metric tons of CO₂e was reduced in 2024 for Taiwan and Macau power companies. The anaerobic digestion power generation system for food waste has achieved an electricity output of 1,656.2 MWh, resulting in a carbon reduction benefit of 818.2 metric tons of CO₂e.

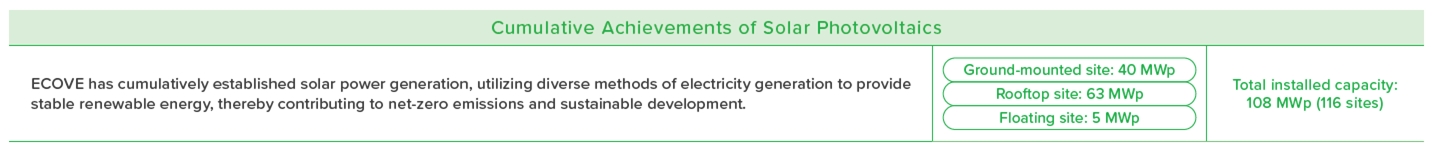

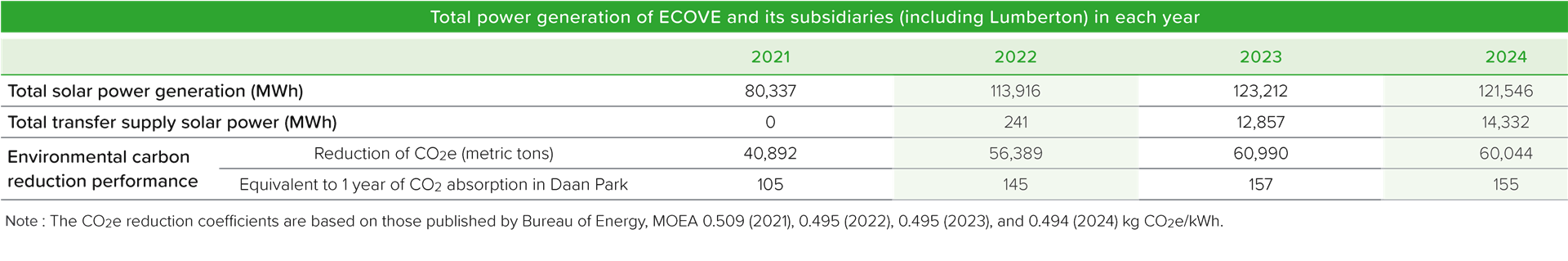

■ Solar Photovoltaics

Solar photovoltaics is one of the world's most important clean energy sources and one of the key development projects of the National Development Council's "12 Key Strategies Toward National Net Zero." ECOVE actively focuses on the development, investment, construction and operation of solar power systems. By the end of 2024, the cumulative developed capacity both domestically and internationally is approximately 164 MW. The Company has collaborated with key partners such as the Taiwan High Speed Rail, Kaohsiung Metro, Taipei Metro, Taichung Metro, Port of Kaohsiung, and Tainan City Government to complete multiple project installations, ensuring a stable supply of renewable energy.

Furthermore, with the integration of renewable energy generation into the power grid, Taiwan Power Company has launched a power auxiliary service market to address its volatility and promote the development of energy storage systems. ECOVE has currently established a 5 MW energy storage project, providing Taiwan Power Company with ancillary services to assist in the stable operation of the power grid. With the amendments to the Electricity Act and the Renewable Energy Development Act, Taiwan has fully opened up direct supply, transfer, and sales transactions for renewable energy, providing enterprises with more options for green electricity procurement. ECOVE has long been deeply engaged in the solar energy sector in Taiwan and officially entered the green electricity trading market in 2021, assisting enterprises in achieving their carbon neutrality and net-zero emission goals. As of the end of 2024, nine green electricity supply contracts have been signed, and efforts to expand collaboration opportunities continue, providing enterprises with the highest quality green energy solutions.

Ground-mounted/Lumberton Photovoltaic Power Plant, New Jersey, USA/9.5 MWp

Rooftop type/Taichung Metro Beitun Depot/2.9 MWp

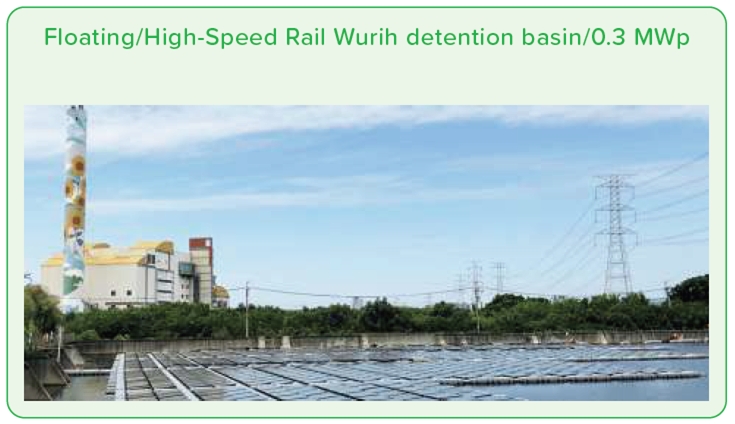

Floating/High-Speed Rail Wurih detention basin/0.3 MWp

Recycling

In an environment with limited resources, ECOVE firmly believes that the circular economy is the key to sustainable operations. Through innovative design, flexible business models, and enhanced resource efficiency, we aim to reduce pollution and waste at the source, creating maximum value with minimal resources. ECOVE is actively promoting the value-added processing of waste materials. For instance, the waste isopropyl alcohol (IPA) produced from the concentration and purification process is being transformed into industrial-grade products for reintroduction into the market. Additionally, wastewater treatment technologies are being utilized to convert wastewater into reclaimed water, which is supplied for industrial cooling or irrigation purposes. These practical actions not only enhance the efficiency of resource utilization but also successfully transform waste into economically valuable resources, achieving a win-win situation for both environmental and economic benefits.

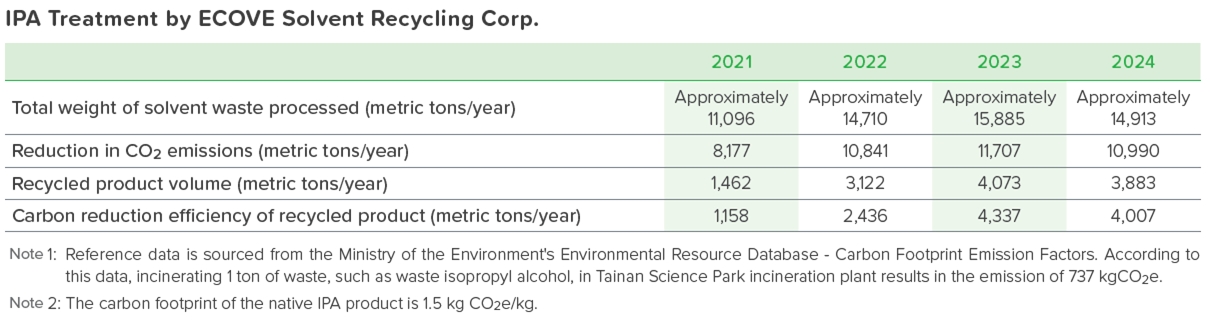

IPA Recovery and Carbon Reduction

ECOVE's subsidiary, ECOVE Solvent Recycling Corp., focuses on the high value-added recycling of waste resources. The technology of recycling is extended to apply to the waste Isopropyl Alcohol (IPA) produced by the semiconductor industry, which is then concentrated and purified to be converted into an industrial-grade product that can be re-sold to the market, thus effectively re-utilizing the resources. In 2024, the processing of approximately 14,913 metric tons of waste isopropyl alcohol equates to a reduction of 10,990 metric tons of carbon dioxide emissions.

Wastewater Treatment and Reclaimed Water

The core operations of ECOVE in the water resource sector encompass three main categories: wastewater treatment, river restoration, and water resource regeneration. We integrate various technologies, including primary treatment, secondary treatment, advanced treatment, and ecological engineering methods, to precisely remove pollutants from water. Furthermore, we aim to achieve the recovery and reuse of water resources, providing comprehensive solutions for the sustainable development of the water environment. To ensure that the effluent quality from the wastewater treatment plant meets standards and is transparent, we have established an automatic continuous monitoring system within the plant. This system monitors the effluent water quality trends around the clock and provides relevant data in real-time for inquiry by regulatory authorities and the public, demonstrating ECOVE's professionalism and responsibility in water resource management.

■ Wastewater Treatment

The current operational site for wastewater treatment is Linkou Water Resources Plant. The treatment process consists of pretreatment and primary treatment to remove garbage and suspended solids from the water, followed by secondary biological treatment to tame microorganisms to remove water-soluble contaminants, and then simple tertiary treatment to produce recycled water for internal/external use. The commercial operation of the Zhongli BOT sewer system is expected to begin on January 1, 2025. In 2024, the total volume of wastewater treated reached 26,275,867 cubic meters. According to the estimation criteria set forth by the Ministry of the Interior's "Technical Specifications for the Design of Sewage Treatment Facilities" (225 liters of sewage per person per day), the efforts and achievements of ECOVE in sewage treatment and water resource reuse are equivalent to serving 116.78 million person-days, which corresponds to processing nearly 4.99 days' worth of sewage generated by the entire population of Taiwan.

■ River Restoration

In terms of river restoration, we are responsible for the operation of the New Taipei City Gravel Contact Oxidation Treatment and the Zhonggang Water Resource Center. We are committed to improving water quality by allowing wastewater to flow through underground gravel areas while aerating to supply oxygen. This process enables microorganisms to attach to the gravel, forming a biofilm that decomposes pollutants and effectively enhances water quality. In addition, the ground facilities combine an ecological park and observation corridors, serving the functions of ecological conservation, recreation, and environmental education. This not only improves the water environment but also provides the public with opportunities to connect with nature and learn about the water resource cycle.

Annual treatment volume for river regulation (cubic meter/year)

Annual treatment volume for river regulation (cubic meter/year)

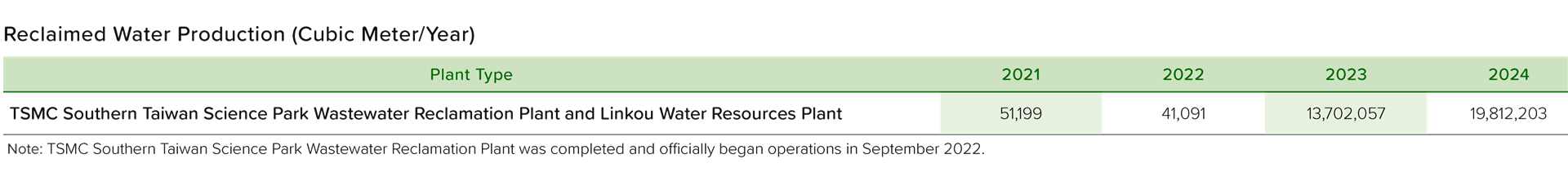

■ Water Reclamation

In the field of water reclamation, we are actively establishing operations, including TSMC Southern Taiwan Science Park Wastewater Reclamation Plant and Linkou Water Resources Plant. Through advanced technology, we convert wastewater into reusable water sources, effectively enhancing the efficiency of water resource circulation. The TSMC Southern Taiwan Science Park Wastewater Reclamation Plant utilizes advanced membrane filtration methods to remove contaminants from water. It employs technologies developed by the Industrial Technology Research Institute, including Biological New Environmental Technology (BioNET), anaerobic fluidized bed (AFB), and fluidized bed crystallizer (FBC), to conduct in-depth treatment of specific pollutants such as boron and nitrogen, ensuring that the water quality meets the standards required for high-tech manufacturing processes. The reclaimed water produced by the plant is consolidated at Yongkang Water Resources Recycling Center and Anping Water Resources Recycling Center, supplying 67,000 cubic meters daily to the high-tech industry. The cumulative production of reclaimed water reached 19,812,203 cubic meters, equivalent to the daily water consumption of 69.032 million people, continuously enhancing the efficiency of water resource utilization.