| Projects |

Tainan Science Park Resource Recycling Center,Taiwan

CTCI provides turnkey services for plant planning, design and operation

The Southern Taiwan Science Park (STSP) is divided into two parks, the Tainan Science Park and the Kaohsiung Science Park. The Tainan Science Park is situated across Xinshi, Shanhua and Anding Districts of Tainan City. During the planning phase of the park, in compliance with the EPA’s Waste Disposal Act and the STSP’s EIA commitments, the governing authority (the Southern Taiwan Science Park Administration) planned and established the “STSP Hazardous Industrial Waste Treatment Center” (hereinafter referred to as "the Center") and adopted the “Build-Operate-Own” (BOO) model to openly select qualified investors. After intense competition among many domestic and foreign companies, CTCI won over the project as the best applicant, and was responsible for implementing the turnkey project for the construction of the Center.

In July 2001, EnviNergy Recycling Corp., a subsidiary of CTCI Group, signed a contract with STSP Provisional Office for the construction and operation of the Center, which has a 17-year concession period. After the construction was completed, due to changes in the market environment, the Center was repossessed by the government agency after the process of asset appraisal in November 2003. For the continuation of the implementation of this project, the government agency re-administered the tender. In the same year, ECOVE Environment Services Corp. (ECOVE), also an affiliate of CTCI Group, took over the responsibility for operation since.

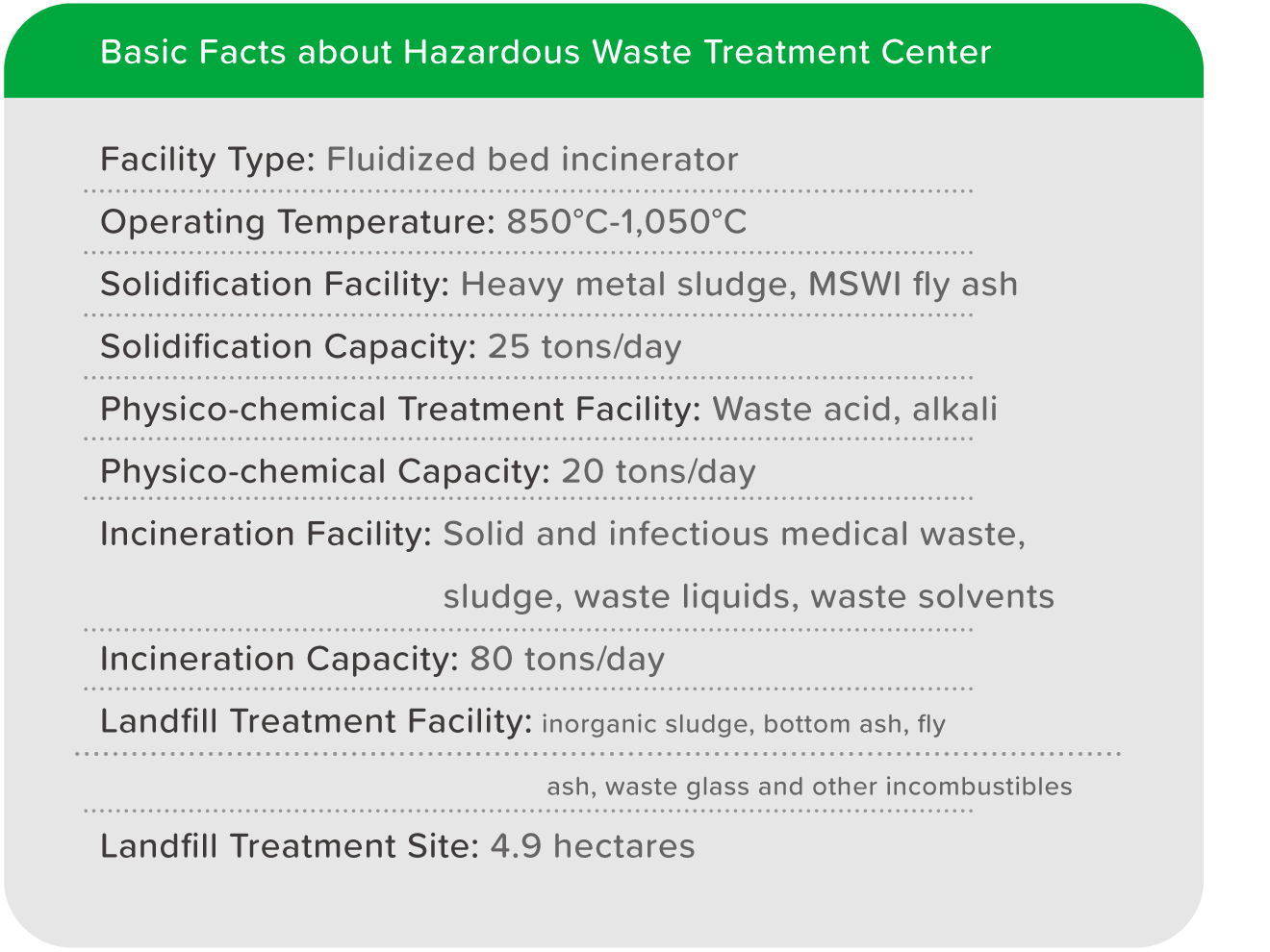

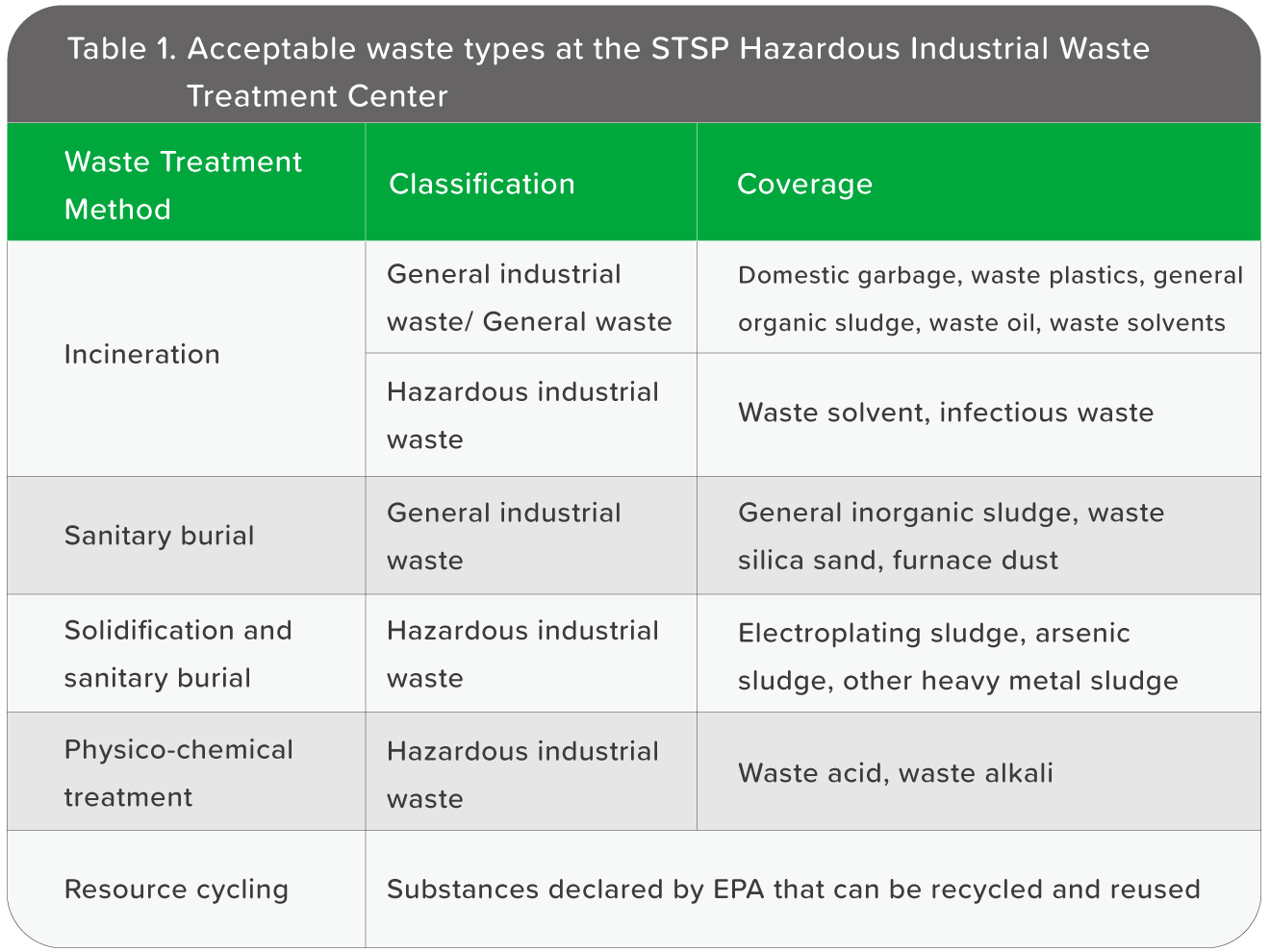

Seek professional resource recovery companies for proper treatment of industrial waste

The daily operation of the STSP’s Tainan Science Park not only processes general household waste, but also processes general industrial waste and hazardous industrial waste, with more than 90 different types in estimation. If classified by waste types, they contain solids, liquids, and sludge waste (see Table 1). These wastes are diverse and complex in nature. Therefore, the planning of the Center's treatment facilities must include functions such as pre-treatment, incineration, solidification, physico-chemical treatment, and landfill burial.

In addition, for the storage and feeding management of waste, such as the storage and disposal arrangements of waste solvents, it is necessary to additionally consider the factors such as the safety of storage, the compatibility among solvents, the corrosion characteristics, the output of production sources, and the frequency of removal and transportation. All these have virtually increased running and operational difficulties for ECOVE.

ECOVE greatly improves the operational efficiency of the Center

Founded in 1994, ECOVE has more than 20 years of experience in the operation and management of large-scale environmental resource management facilities such as incineration power plants. It has in-depth knowledge of the complex chemical and physical properties of hazardous and special wastes. The main performances achieved so far by ECOVE since taking over the operation of the Center are described below:

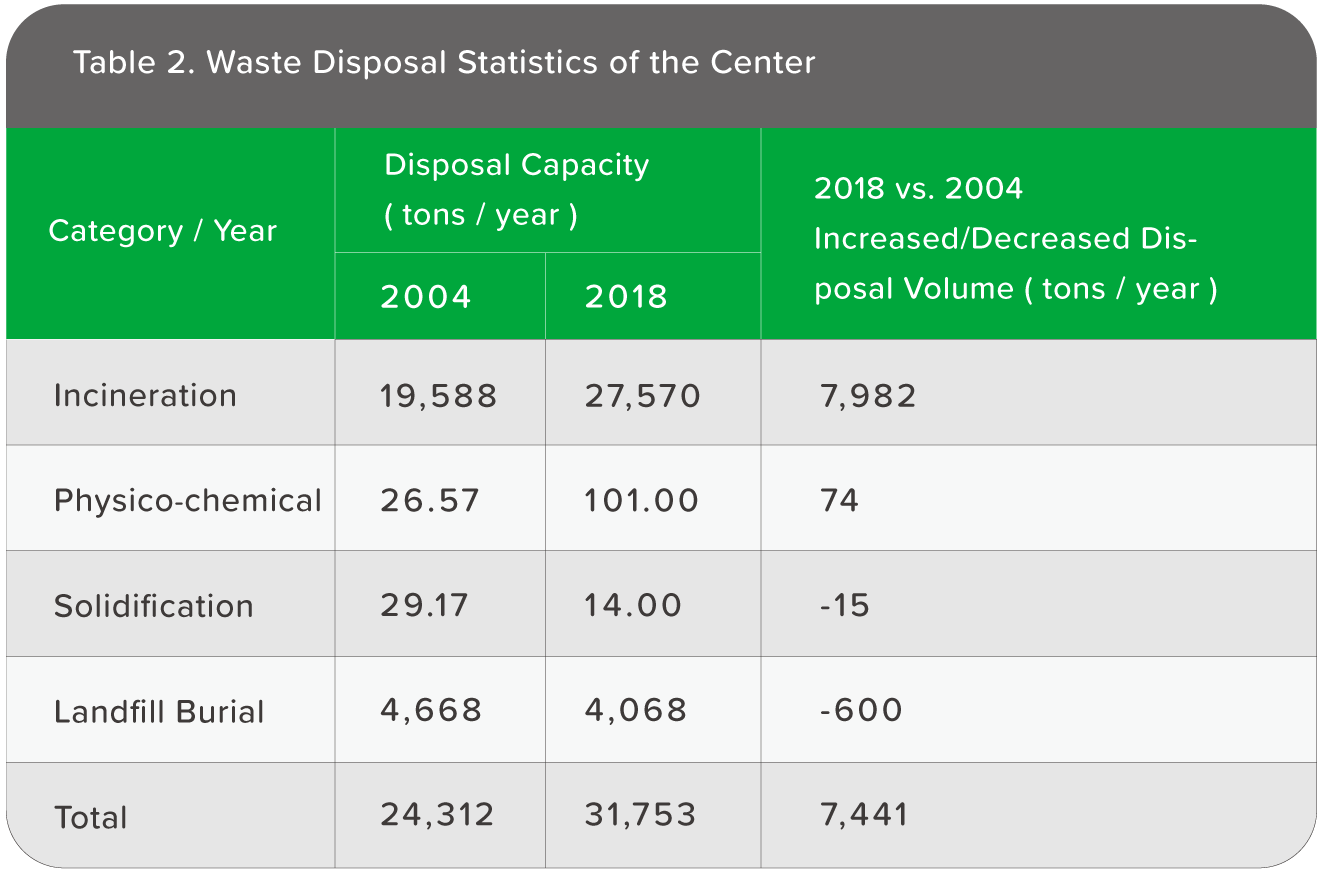

A.) Increase in waste disposal volume

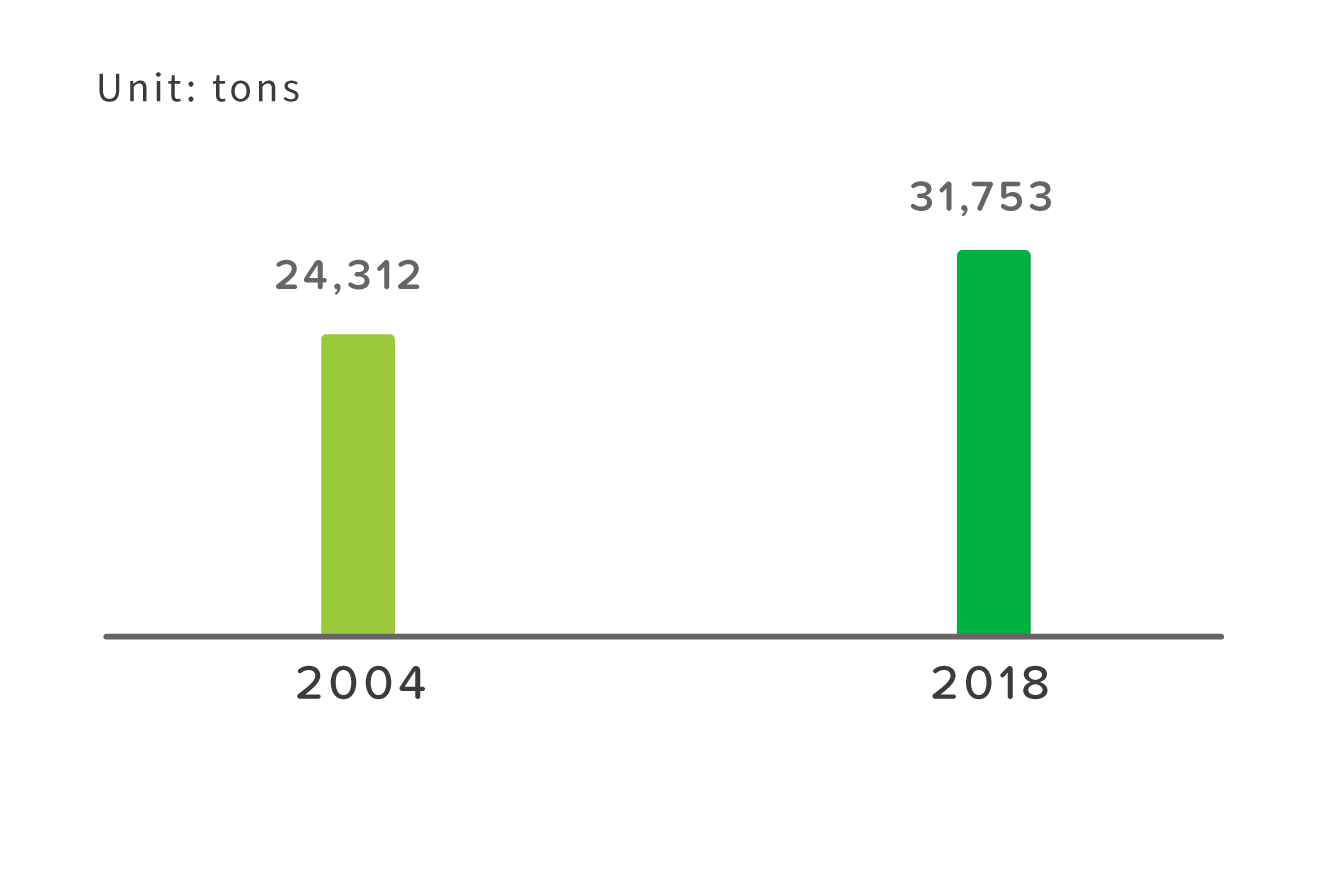

During the period when ECOVE is running and operating the Center, the waste disposal has achieved the goals of “reduction,” “stability,” and “harmless.” In 2018, the incineration volume increased by 7,982 tons compared to that in 2004. In landfill disposal, the Center has successfully reduced 600 tons of landfill waste thanks to its promotion of the zero-burial landfill policy and assistance to industries in reducing waste and recycling. Comparing 2018 to 2004, the total waste disposal volume has increased by 7,441 tons (see Table 2 and Figure 1).

Figure 1. Change in total disposal volume at the Center.

B.) Loss on ignition of bottom ash

ECOVE adopts quartz sand in the Center as the heat transfer medium in the furnace to transfer heat to the pretreated or homogeneous waste. Through the air turbulence inside the hearth, the waste and heat transfer medium are forced to flow and burn on the sand beds. With this method, the loss on ignition of bottom ash after fluidized bed incineration is about 0.1%, which is much lower than the loss on ignition of bottom ash of the large incinerators (about 2-3%), indicating that the incineration effect is good and the combustion efficiency is high.

C.) Air quality monitoring and air pollution reduction

ECOVE adopts dry scrubbing and selective non-catalytic nitrogen oxide reduction in air pollution control, effectively remove acid gases and reduce flue dust. ECOVE also closely monitors the emissions of hydrogen chloride, sulfur oxides, nitrogen oxides, and carbon monoxide using the air pollution continuous monitoring equipment.

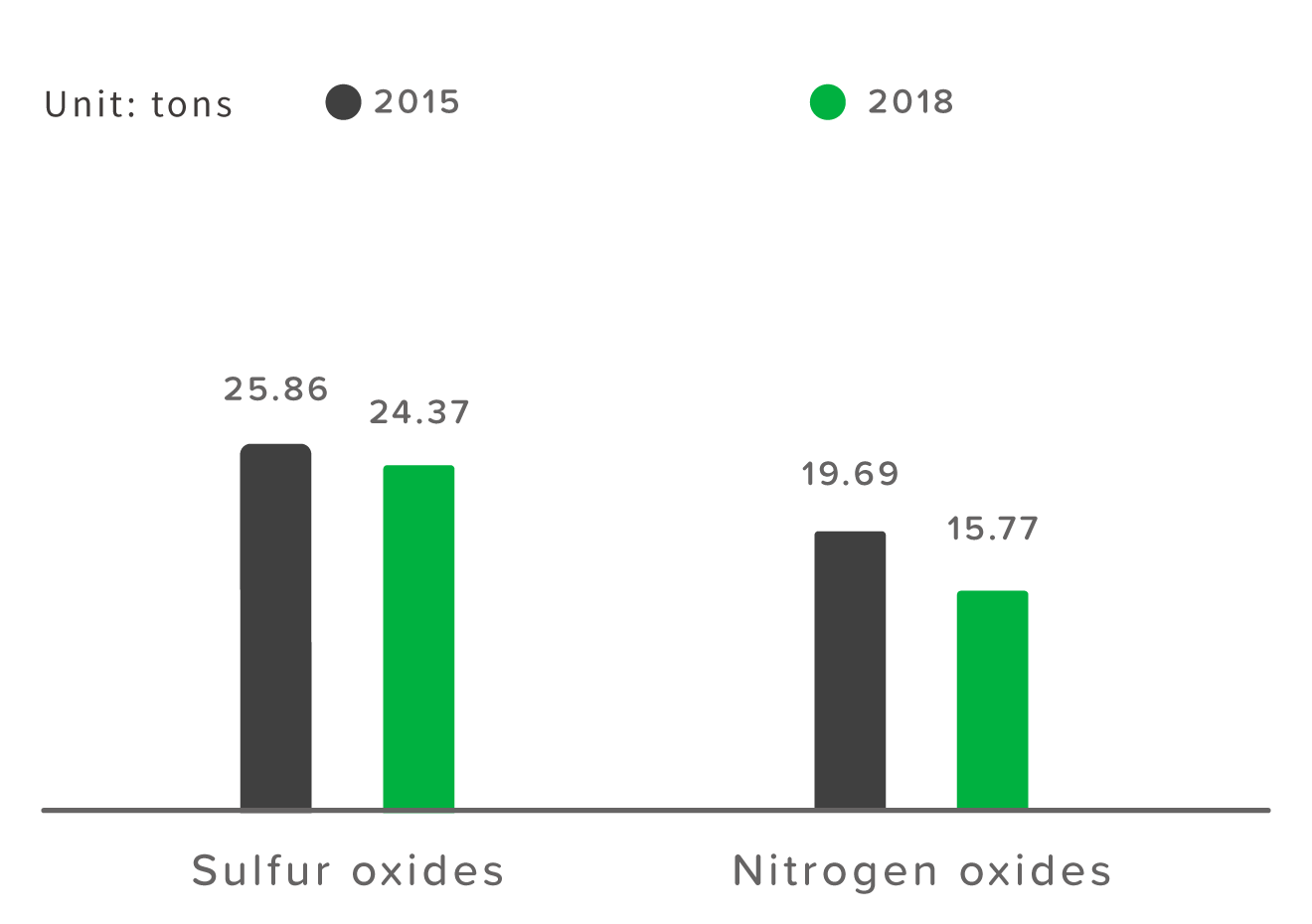

At the same time, daily inspections and verifications of the nature of wastes are strictly carried out to analyze the sulfur, chlorine, and calorific value components of the waste. The test results are used by the Center to adjust the incineration parameters to achieve the goal to handle waste disposal properly. The reduction of air pollutants from stationary sources in the past three years has reached 5.41 tons (see Figure 2).

Figure 2. Air pollutant emissions comparison from stationary sources at the Center

Effective energy saving and water saving

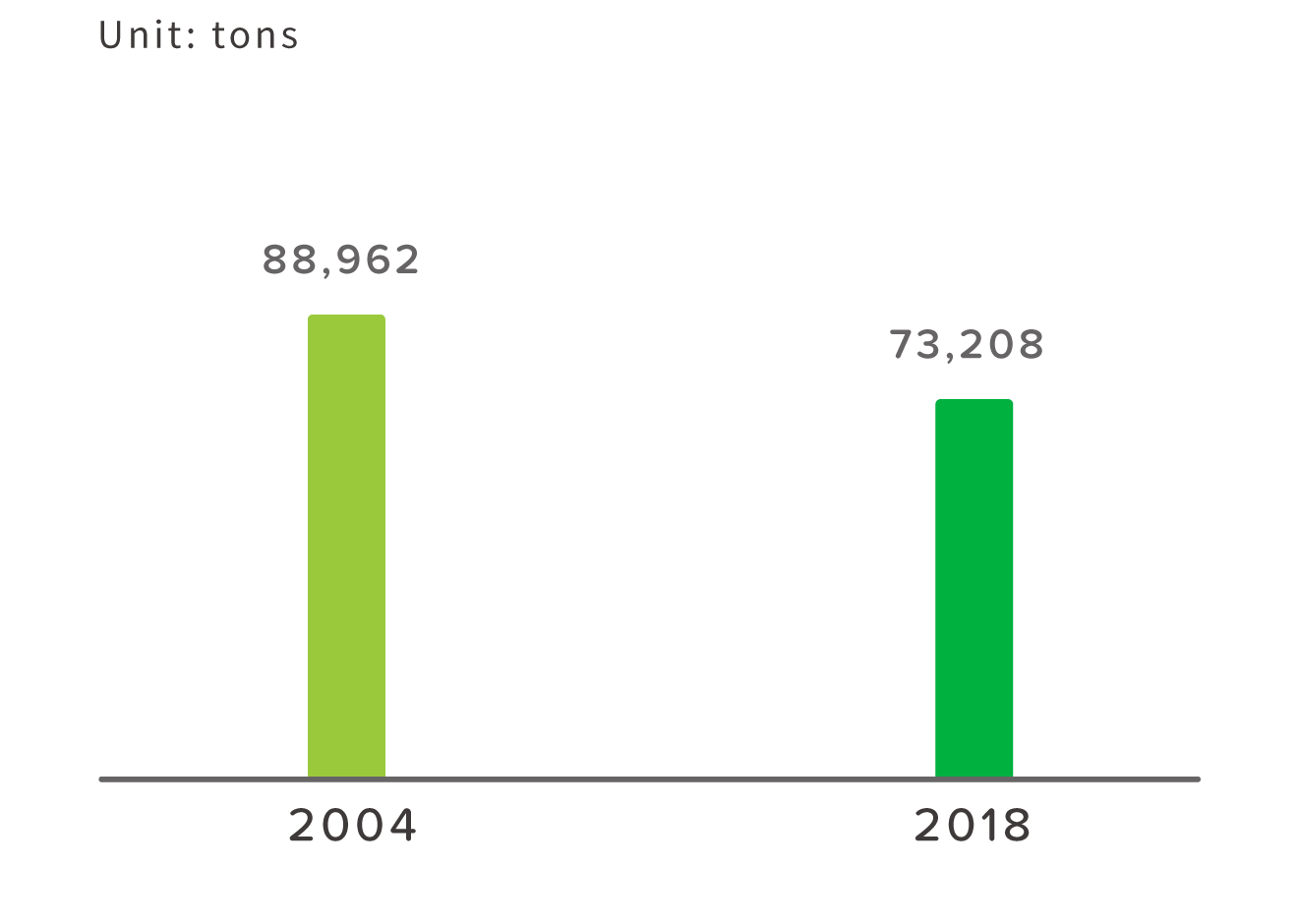

With the core concept of "Every Resource Counts", our colleagues in ECOVE have adhered to the principle of recycling and reuse of resources, and implemented water-saving measures for domestic and process water in the facility. In 2018, we saved 15,754 m3/year compared to 2004 (see Figure 3).

Figure 3. Water consumption statistics at the Center.

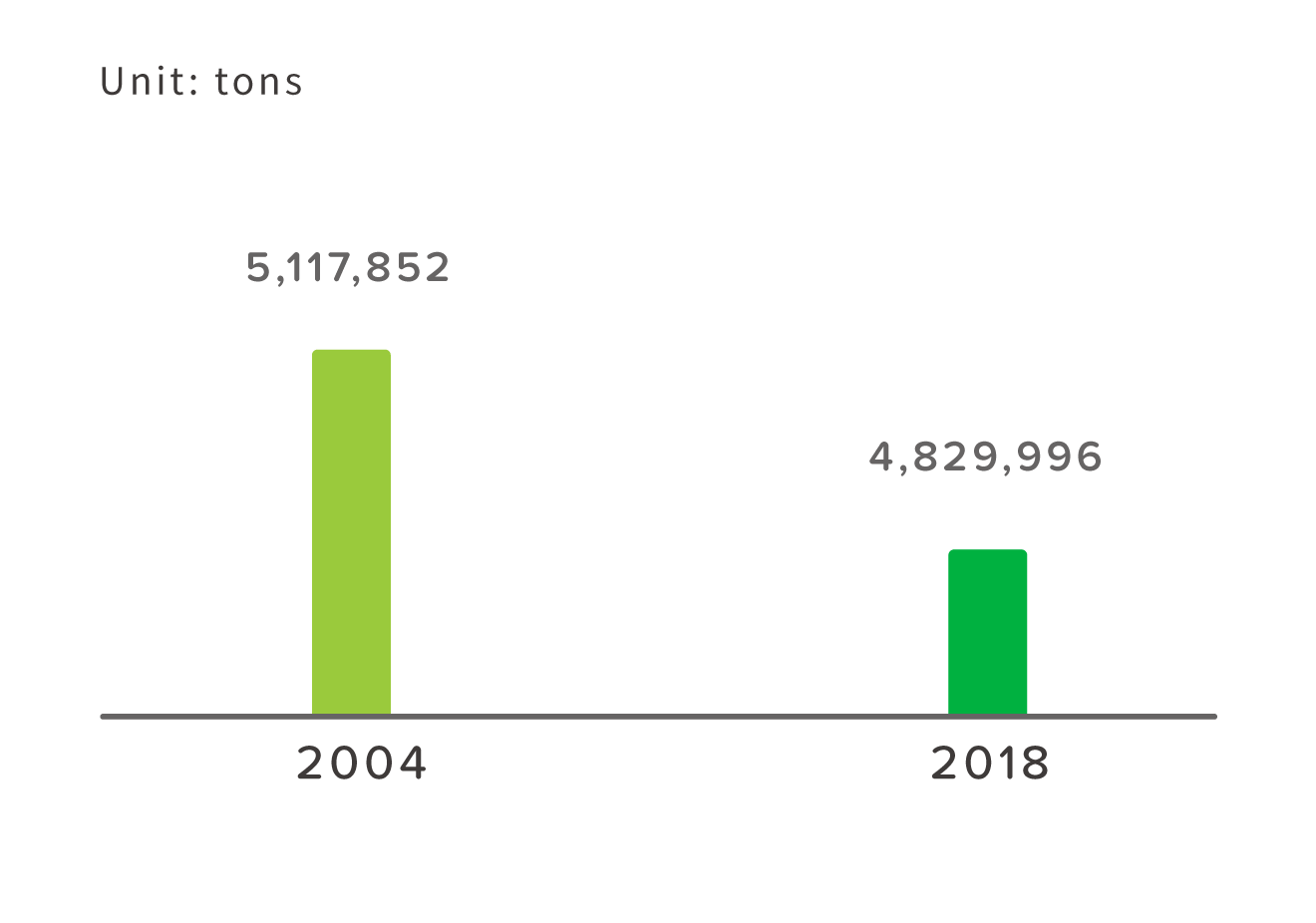

At the same time, ECOVE has also been promoting energy conservation and carbon reduction at the Center. Through the optimization of equipment maintenance and management, energy-saving and carbon reduction plans and energy conservation measures, coupled with minimizing non-scheduled shutdowns, we have been able to achieve annual energy savings greater than 1%. To further increase electricity savings and continue to promote energy saving measures for processes and lighting facilities. In 2018, we saved 287,856 kWh compared to 2004 (Figure 4).

Figure 4. Electricity consumption statistics at the Center.

Why ECOVE?

We can provide a comprehensive industrial waste solution for the clients to achieve the goals of both industrial economy and sustainable development of the environment.

The industrial manufacturing processes in the Science Park are changing rapidly. The types of waste to be treated and disposed of are complex in nature. The process flow needs to integrate different treatment mechanisms, including incineration, solidification, Physico-chemical, and landfill to achieve effective handling and operation. Since ECOVE took over the operation of the facility, there has no any dispute in issues such as public hazards, public protests, and irregularities.

ECOVE has 20 years of professional experience in the operation and maintenance of incineration plants. Our hands-on operating experience of incineration plants ranges from the urban waste incineration plant to the cleanup, operation, and management of hazardous industrial waste in the Science Park. We are familiar with the relevant environmental protection regulations and the characteristics of various types of hazardous industrial wastes and can meet the waste disposal needs of the governing authorities and various businesses in the Science Park.

The STSP’s long-term vision for sustainable development is to become an environmentally green science park with “clean production, comfortable life, and rich ecology." After taking over the operation of the Center, ECOVE has been actively creating an ecological environment for the STSP and has won the “ROC Enterprise Environmental Protection Award - Silver Award” for the third consecutive year. ECOVE was also awarded the “Environmental Protection Honor Award", making the Center the first one to ever receive this award among all the waste disposal centers in Taiwan’s science parks.

The Center has won the “ROC Enterprise Environmental Protection Award - Silver Award” for the third consecutive year. ECOVE Environment Services Corporation President H.H.Tiao (2nd from the left) and Tainan Science Park Resource Recycling Center manager H.C. Han(1st from the left) at the ceremony.

The Center has won the “ROC Enterprise Environmental Protection Award - Silver Award” for three years in a row, and was also awarded the “Environmental Protection Honor Award".

At the same time, ECOVE has also introduced relevant energy management systems, making it not only the first waste disposal entity in Taiwan that has acquired the "PAS2050 Carbon Footprint Certification", "ISO 50001 Energy Management System Certification" and "Outstanding Energy Saving Performance Award", but also passed the "ISO 14064-1 Greenhouse Gas Inventory Certification." In addition to positively enhancing the image of the Client (Southern Taiwan Science Park Bureau) and the Science Park, these achievements can also make the Center become a demonstration facility for energy saving and carbon reduction to all public and private waste treatment plants in Taiwan, making STSP a model for sustainable green science park.